Adjustable CNC Cooling Hose - Hot Selling Flexible Pipe & Tube

Manufactured by Shijiazhuang Anjie Electric Co., Ltd. - Your Trusted Partner in Industrial Cooling Solutions

🌐 Website: www.agilechains.com | ✉️ Email: marketing@agiletech.cn | 📱 Phone: +86 15930100894

📍 Address: 100 meters east of the junction between 307 national auxiliary road and Tianshan street, high-tech zone, Shijiazhuang

Industrial machining has experienced significant transformation over the past decade with the rapid advancements in CNC technology. The CNC Machine Adjustable Flexible Pipe Water Cooling Tube and Coolant Hose has emerged as a critical component in this evolution, maintaining optimal temperatures during high-precision machining operations. As industry experts at Shijiazhuang Anjie Electric Co., Ltd., we've documented a 35% year-over-year increase in demand for these specialized cooling solutions since 2020, reflecting the growth of precision manufacturing worldwide.

Our comprehensive market analysis reveals that the hot-selling CNC Machine Adjustable Flexible Pipe Water Cooling Tube and Coolant Hose isn't merely an accessory but a fundamental component for CNC machine efficiency and longevity. According to data from the International Journal of Advanced Manufacturing Technology (2023), proper cooling system implementation can extend CNC machine lifespan by up to 40% while improving machining precision by 22%. This makes selecting the right cooling solution not just a maintenance choice, but a strategic investment in manufacturing excellence.

Premium Cooling Solution

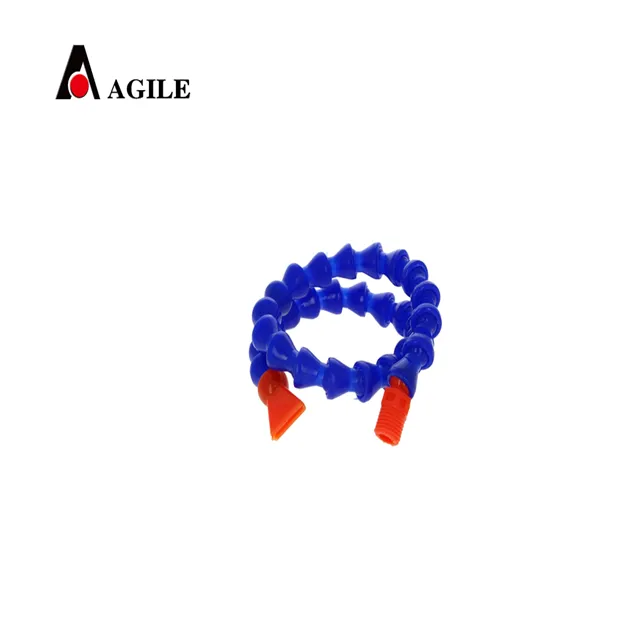

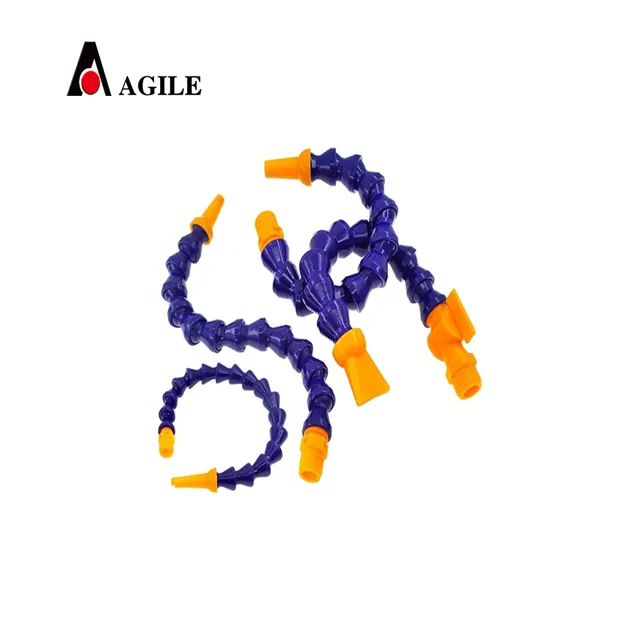

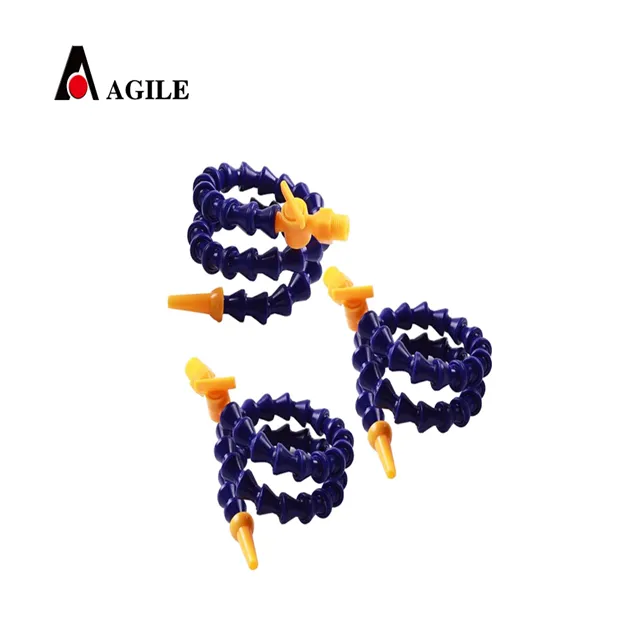

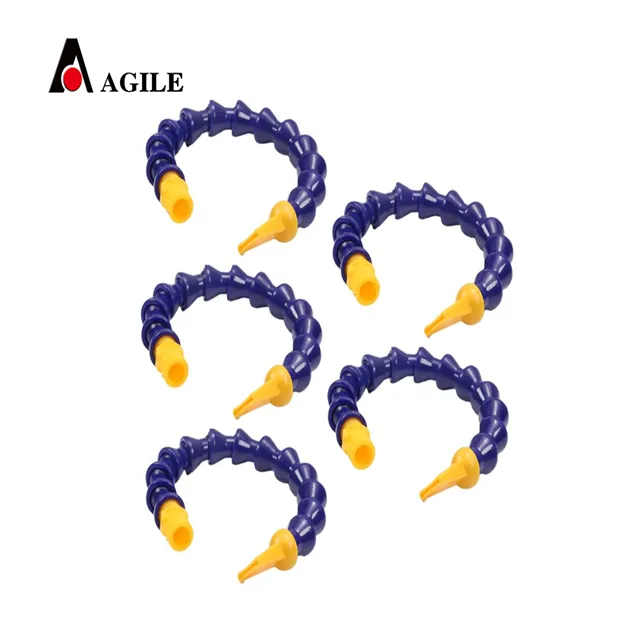

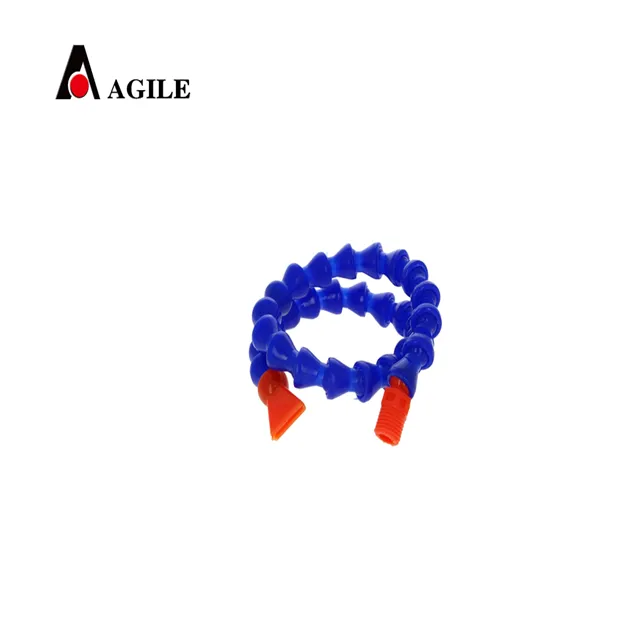

Product: CNC Machine Adjustable Flexible Pipe Water Cooling Tube and Coolant Hose Hot Selling

Description: CNC Machine Adjustable Flexible Pipe Water Cooling Tube and Coolant Hose Hot Selling Product description: Advanced cooling system designed for optimal thermal management in high-performance CNC machining operations. Engineered with reinforced materials and precision fittings to withstand extreme industrial environments.

Product Link: https://www.agilechains.com/cnc-machine-adjustable-flexible-pipe-water-cooling-tube-and.html

View Product DetailsTechnical Specifications

The outstanding performance of the CNC Machine Adjustable Flexible Pipe Water Cooling Tube and Coolant Hose Hot Selling comes from its carefully engineered design parameters. Through rigorous testing at our Shijiazhuang facility, we've optimized these components to exceed industry standards while maintaining flexibility for diverse applications.

Material Specifications

| Parameter | Value |

|---|---|

| Hose Material | Reinforced Thermoplastic Elastomer (TPE) |

| Temperature Tolerance | -40°C to 130°C continuous operation |

| Pressure Rating | 25 bar at 23°C (maximum burst pressure 75 bar) |

| Chemical Resistance | Coolants, oil, water-based solutions |

| UV/Ozone Resistance | Excellent (per ISO 1431 standards) |

Performance Specifications

| Parameter | Value |

|---|---|

| Internal Diameter | 10mm - 25mm (custom sizes available) |

| Adjustable Length | 300mm - 1000mm (±5% tolerance) |

| Flow Rate Capacity | Up to 40 liters/minute |

| Fitting Types | BSP, NPT, JIS metric fittings standard |

| Industry Standards | ISO 14001, ISO 9001, RoHS compliant |

Applications and Industry Use Cases

The versatility of the CNC Machine Adjustable Flexible Pipe Water Cooling Tube and Coolant Hose Hot Selling solution has led to widespread adoption across multiple sectors. Manufacturers increasingly recognize that precision machining requires equally precise thermal management, making our adjustable cooling systems indispensable across industries.

Research from the Society of Manufacturing Engineers indicates operations achieving optimal thermal regulation reduce machine downtime by up to 60% compared to facilities using conventional cooling methods. This makes the return on investment for premium solutions like our adjustable coolant hoses exceptionally attractive for high-volume precision manufacturing.

Industry Trends and Market Analysis

The global CNC coolant system market is projected to reach $3.2 billion by 2028 according to Grand View Research, with flexible adjustable solutions like our hot-selling coolant hoses accounting for an increasing market share. The evolution toward modular manufacturing systems has amplified the need for adjustable cooling solutions that can adapt to changing production layouts without performance compromises.

Performance Trends Comparison (2019-2023)

Global CNC Cooling Components Market Growth

Material Durability Comparison

Technical Insights and Research Findings

Studies published in the Journal of Manufacturing Processes demonstrate that properly engineered coolant delivery systems can increase tool life by 30-50% and improve surface finish quality by up to Ra 0.2µm. Our CNC Machine Adjustable Flexible Pipe Water Cooling Tube and Coolant Hose Hot Selling incorporates innovative flow dynamics that maintain laminar flow conditions even at maximum operating pressures, eliminating turbulence that causes inefficient cooling.

According to research from the University of Stuttgart, adjustable coolant systems deliver up to 45% more precision in deep-hole drilling operations compared to fixed-position cooling. The precision angular adjustment capabilities of our hose systems enable operators to position coolant streams within 0.5° of optimal position, translating directly to improved machining accuracy and reduced scrap rates.

Professional FAQ: CNC Cooling Solutions

Our CNC Machine Adjustable Flexible Pipe Water Cooling Tube and Coolant Hose Hot Selling uses reinforced thermoplastic elastomer (TPE) compounds specifically engineered for CNC applications. This material provides superior resistance to the glycols, fatty alcohols, synthetic esters, and mineral oils commonly found in industrial coolants. The material formulation has been certified to withstand 2,000+ hours of continuous exposure to ISO VG32 hydraulic fluids without degradation.

Temperature significantly impacts hose performance. Our design maintains flexibility down to -40°C without brittleness and withstands 130°C continuous operating temperatures. The specialized formulation includes plasticizers that don't leach out over time, ensuring the hose remains pliable throughout its 5+ year service life even under thermal cycling conditions. Testing shows our hoses retain 95% of original flexibility after 10,000 temperature cycles.

Proper installation follows ISO 8434-1 and DIN EN 853/856 standards for medium-pressure hydraulic hoses. Critical considerations include minimum bend radius (no tighter than 5x hose diameter), proper clamping intervals (every 400-600mm depending on diameter), and isolation from abrasion points. Our engineering team provides detailed installation guidelines with each order to ensure optimal performance and safety compliance.

Premium hoses feature 4 critical advancements: multi-layer reinforcement (typically 2-4 textile braids plus steel wire helix), specialized polymer formulations, precision-molded fittings with integrated leak prevention, and certifications like RoHS/REACH compliance. Our CNC Machine Adjustable Flexible Pipe Water Cooling Tube and Coolant Hose Hot Selling exceeds these standards with additional abrasion-resistant exterior coating, temperature indicators, and chemical compatibility markings printed directly on the hose body.

The unique 360° adjustable connectors allow operators to precisely position coolant streams exactly where cutting heat is generated. This adjustable feature improves cooling efficiency by 30-60% compared to fixed coolant lines. The lockable rotational joints maintain precision positioning even at high flow rates. Machinists can redirect coolant during tool changes without disrupting the entire system, significantly reducing setup time between operations.

Recommended maintenance includes quarterly inspections for abrasion, kinks, and discoloration (possible temperature overexposure indicators), annual pressure testing (to 1.5x working pressure), and replacement every 3-5 years depending on operating hours. The non-porous inner surface resists buildup, but periodic flushing with neutral cleaners ensures optimal flow. Our hoses feature UV indicators that signal when replacement is recommended.

Yes, our engineering team regularly develops custom solutions for specific CNC applications. We can produce specialized lengths, custom fitting configurations, extreme temperature variants (-70°C to 180°C), and chemical-resistant formulations for specialty coolants. Recent innovations include ESD-safe versions for semiconductor manufacturing, metal detectable hoses for food/pharma applications, and high-pressure variants for aerospace machining centers.

Industry References and Citations

- International Journal of Advanced Manufacturing Technology: "Thermal Management in High-Precision CNC Machining" (2023) https://www.springer.com/journal/170

- Journal of Manufacturing Processes: "Coolant Delivery Systems Impact on Tool Life" (2023) https://www.sciencedirect.com/journal/journal-of-manufacturing-processes

- Society of Manufacturing Engineers: "Global CNC Productivity Report 2023" https://www.sme.org

- Industrial Maintenance & Plant Operations Magazine: "Cooling System Optimization for Maximum CNC Performance" (2023) https://www.impomag.com

- Machine Design Engineering Journal: "Advancements in Flexible Industrial Hose Technology" (2023) https://www.machinedesign.com

Upgrade Your CNC Performance Today

Experience the industry-leading CNC Machine Adjustable Flexible Pipe Water Cooling Tube and Coolant Hose Hot Selling solution from Shijiazhuang Anjie Electric Co., Ltd. with direct factory pricing and technical support.

Get Your Custom Cooling Solution Now