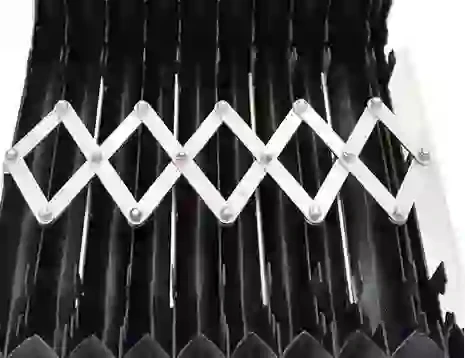

accordion bellows protector

The Importance of Accordion Bellows Protectors in Machinery

In the world of machinery and manufacturing, the longevity and efficiency of equipment play a critical role in operational success. Among the various components that ensure the smooth functioning of machines, accordion bellows protectors stand out as essential protective elements. These flexible coverings provide significant benefits, safeguarding delicate parts from environmental factors and enhancing overall machine performance.

Understanding Accordion Bellows Protectors

Accordion bellows protectors are flexible, accordion-shaped covers, typically made from materials like rubber, plastic, or fabric. Their primary function is to shield moving parts from dust, debris, moisture, and other contaminants that can lead to wear and tear. This protective barrier is crucial in various applications, particularly in CNC machines, robotics, and other industrial equipment where precision is paramount.

The design of accordion bellows allows them to expand and contract as machinery operates, effectively accommodating the movement of components while maintaining a tight seal against external elements. This adaptability not only protects the internal parts but also ensures that lubrication remains intact and operational efficiency is not compromised.

Benefits of Using Accordion Bellows Protectors

1. Protection from Contaminants One of the primary benefits of accordion bellows protectors is their ability to keep harmful substances away from critical components. Dust and debris can cause significant damage over time, leading to costly maintenance and repairs. By blocking these contaminants, bellows protect machinery and extend its lifespan.

2. Improved Energy Efficiency Machines that operate under clean conditions are more energy-efficient. The absence of contaminants ensures that all moving parts function smoothly, reducing friction and energy loss. This efficiency can lead to considerable savings in operational costs.

accordion bellows protector

3. Enhanced Safety In industrial settings, safety is paramount. Accordion bellows protectors can minimize the risk of injury by covering sharp edges and moving parts. This safety feature is critical for operators working in close proximity to machinery.

4. Versatility in Application Accordion bellows protectors are versatile and can be used across a wide range of industries, from manufacturing and automotive to aerospace and medical devices. Their adaptability makes them an ideal choice for various machinery types, ensuring comprehensive protection.

5. Customizability Many manufacturers offer custom accordion bellows to meet specific dimensions and application requirements. This customization enhances their effectiveness, ensuring a perfect fit for the equipment they protect.

Installing and Maintaining Accordion Bellows Protectors

Proper installation and maintenance of accordion bellows protectors are crucial to their effectiveness. During installation, it is essential to ensure that the bellows are correctly sized and fitted without any gaps. Regular inspections should be conducted to identify any signs of wear or damage. Any tears or holes should be addressed promptly to maintain protective integrity.

Cleaning the bellows periodically is also important. While they are designed to keep debris out, dust and grime can accumulate on the surface over time. A simple wipe down or a gentle wash with appropriate cleaning solutions can help prolong the lifespan of the protectors.

Conclusion

In conclusion, accordion bellows protectors are invaluable components in modern machinery. They provide essential protection against contaminants, enhance energy efficiency, and contribute to workplace safety. Their versatility and customizability make them suitable for a wide array of applications, ensuring they can meet the diverse needs of various industries. Investing in high-quality accordion bellows protectors not only enhances the performance and longevity of machinery but also protects workers, making them a wise choice for any operation focused on efficiency and safety.