Flexible Protective Covers for Accordion Mechanisms and Bellows Systems

Understanding Accordion Bellows Covers Functionality and Importance

Accordion bellows covers are essential components in various mechanical applications, particularly in machinery that requires protection for moving parts. Used extensively in manufacturing, robotics, and automation, these specialized covers serve to shield delicate mechanisms from dust, dirt, moisture, and other contaminants that could lead to wear and tear.

The design of accordion bellows is tailored to accommodate linear motion while offering maximum protection. Made from flexible materials, they expand and contract in a manner akin to an accordion, allowing for significant movement without compromising the integrity of the cover. This elasticity is crucial for environments where space is limited and where machine components must have the ability to move freely.

One of the major functions of accordion bellows covers is to safeguard critical mechanical elements such as shafts, pistons, and linear guides. By providing a protective barrier, these covers help prolong the lifespan of machinery, reducing the need for frequent repairs and maintenance. In industries like CNC machining, where precision is paramount, having proper protective measures in place is vital to ensuring consistent quality and efficiency.

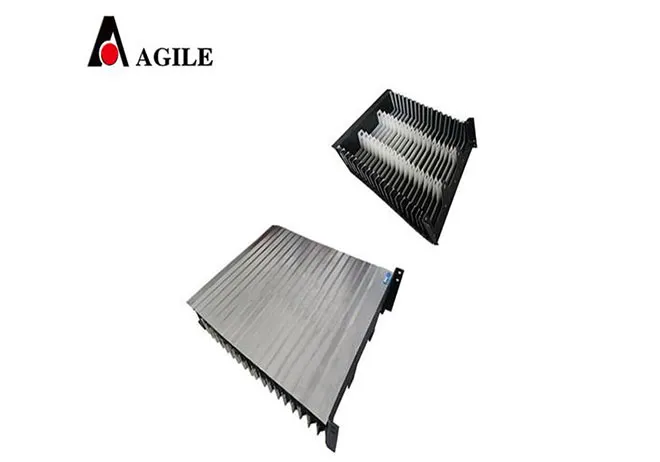

accordion bellows cover

In terms of materials, accordion bellows can be made from various substances, including rubber, plastic, or composite materials. The choice of material often depends on the specific application's requirements, such as temperature tolerance, chemical resistance, and environmental exposure. For instance, a manufacturing facility that deals with cutting oils and metal shavings would benefit from bellows covers made of resistant materials that can withstand harsh conditions.

Installation of accordion bellows covers is typically straightforward. However, careful attention must be paid to ensure they are properly fitted to the equipment. Any gaps or improper seals can lead to the very contaminants these covers are designed to keep out, ultimately compromising the equipment's integrity. Regular inspection and maintenance of the bellows themselves are essential to catch any signs of wear or damage early on, ensuring optimal performance.

Moreover, in the face of increased automation and the need for more sophisticated machinery, the demand for effective protective components like accordion bellows covers continues to grow. As industries evolve, manufacturers are exploring innovative designs and materials to enhance the efficacy of these covers, ensuring they meet the needs of modern machinery.

In conclusion, accordion bellows covers are a vital component in protecting sensitive machinery from environmental factors. Their ability to adapt to movement while providing robust protection is invaluable across numerous industries. Investing in high-quality accordion bellows covers is not merely a choice; it’s a necessity for maintaining the longevity and efficiency of mechanical systems in today’s fast-paced manufacturing landscape.