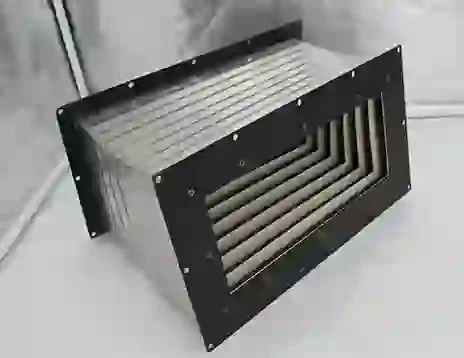

Flexible Accordion Bellows Cover for Enhanced Protection and Versatility in Machinery Applications

The Importance of Accordion Bellows Covers in Engineering Applications

Accordion bellows covers are essential components used across various industries for protecting mechanical systems. Their unique design, resembling an accordion, allows them to expand and contract while maintaining flexibility. This characteristic makes them ideal for safeguarding intricate machinery, especially in environments where dust, debris, and other contaminants pose a threat to operational integrity.

Understanding Accordion Bellows Covers

Accordion bellows covers are essentially protective casings made from flexible materials, such as rubber, plastic, or fabric. They are engineered to shield moving parts, such as rail tracks, screws, and linear guides, from external elements while allowing for unrestricted motion. This design is particularly beneficial in applications involving linear motion, where components must traverse long distances while maintaining precision and safety.

One of the primary functions of these covers is to prevent contamination from entering sensitive areas of machinery. Dust, dirt, and other particles can lead to wear and tear on mechanical components, resulting in reduced efficiency and increased maintenance costs. By using accordion bellows covers, companies can significantly extend the lifespan of their equipment and minimize downtime related to repairs or replacements.

Applications in Various Industries

Accordion bellows covers find use in a variety of fields, including manufacturing, robotics, and aerospace. In manufacturing, for instance, they are commonly used on CNC machines, which require high precision and cleanliness to produce high-quality products. The covers protect these machines from metal shavings, coolant splashes, and other contaminants that could interfere with their operation.

In the robotics industry, accordion bellows are used to safeguard the moving parts of robotic arms and other automated systems. These systems are often exposed to harsh environments and require robust protection to ensure they can operate smoothly without failure.

The aerospace sector also benefits from these protective covers. Aircraft components are subject to extreme conditions, and accordion bellows covers help protect delicate mechanisms from debris and environmental factors. This protection is crucial in maintaining the reliability and safety of aircraft systems.

accordion bellows cover

Material Selection and Customization

The effectiveness of accordion bellows covers largely depends on the materials used in their construction. Manufacturers often prioritize materials that offer excellent durability, flexibility, and resistance to environmental factors. Common choices include neoprene, polyurethane, and various engineered plastics. Each material has unique properties suited for specific applications, such as high-temperature resistance or chemical resistance.

Customization is another significant aspect of accordion bellows covers. Manufacturers can tailor the size, shape, and material of the covers to meet the specific needs of the application. This bespoke approach ensures that the covers provide the optimal level of protection for different environments and operating conditions.

Benefits of Using Accordion Bellows Covers

The incorporation of accordion bellows covers into mechanical systems offers numerous advantages. By providing a reliable barrier against contaminants, they help to maintain the cleanliness of equipment, which is critical for optimal performance. Additionally, their flexible design allows for smooth movement, reducing stress on mechanical components and potentially lowering maintenance costs over time.

Moreover, the use of these covers contributes to overall safety in the workplace. By preventing debris from interfering with machinery, the risk of accidents is minimized, fostering a safer working environment.

Conclusion

In summary, accordion bellows covers represent a vital component in modern engineering and industrial applications. Their ability to protect sensitive mechanisms from contaminants, coupled with their flexibility and customizability, makes them an indispensable asset in various sectors. As technology advances and the demand for precision and reliability escalates, the role of accordion bellows covers will continue to grow, ensuring that machinery operates efficiently and safely in challenging environments.