Accordion Style Cover for Enhanced Design and Functionality

Exploring the Versatility of Accordion Bellow Covers

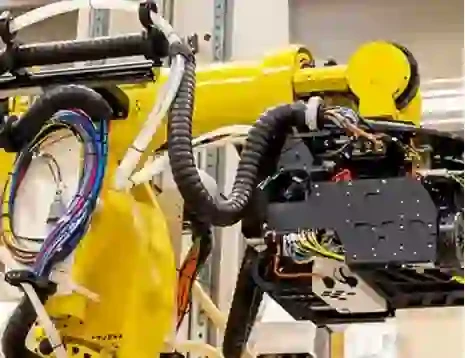

Accordion bellow covers, often simply referred to as bellows, have become an integral part of modern machinery and equipment. These unique structures provide essential protection and functionality, making them a popular choice across various industries. In this article, we will explore the significance, design, manufacturing, and applications of accordion bellow covers, highlighting their versatility and importance in enhancing the longevity and efficiency of machinery.

What are Accordion Bellow Covers?

Accordion bellow covers are flexible, elongated covers that resemble the folds of an accordion. They are typically made from durable materials such as rubber, plastic, or metal. Their primary purpose is to shield components from dust, dirt, debris, and moisture, which can cause severe damage or malfunction. Additionally, they help prevent the ingress of harmful substances and provide a degree of insulation against temperature variations.

Significance in Machinery

The importance of accordion bellow covers cannot be overstated. In many industrial applications, precision machinery is rendered useless if its internal components are contaminated or damaged. Bellow covers serve as a protective barrier, optimizing the performance and lifespan of machines.

Moreover, in environments with high moisture or chemical exposure, bellows can prevent corrosion and degradation, ensuring that machinery operates smoothly. They also reduce the risk of accidental contact with sharp edges or moving parts, thereby enhancing workplace safety.

Design and Customization

One of the key advantages of accordion bellow covers is their customizable design. Manufacturers can create bellows in various sizes, shapes, and materials to fit specific machinery requirements. The folds in the bellows allow for flexible movement, accommodating the machinery's range of motion while still providing maximum protection.

accordion bellow cover

Design considerations may include factors such as the operating environment, expected temperature ranges, and the types of contaminants the bellow covers will face. For instance, in high-temperature applications, silicone or specialized rubber compounds may be used, while in environments with exposure to chemicals, materials resistant to such substances are essential.

Manufacturing Process

The manufacturing process of accordion bellow covers typically involves several stages. First, manufacturers assess the specific requirements based on the application and environment. Next, they select appropriate materials that match these needs. The materials are then cut and shaped to form the required bellow structure.

The assembly may involve techniques such as welding, bonding, or sewing, depending on the material used. Lastly, rigorous quality control measures are conducted to ensure that the final product meets industry standards for durability and performance.

Applications Across Industries

Accordion bellow covers are used in a plethora of applications across different sectors. In the automotive industry, they protect machinery components such as steering racks, shafts, and transmissions. In manufacturing, they safeguard CNC machines, milling equipment, and lathes from harmful contaminants.

The aerospace sector also employs bellows to protect parts of aircraft engines and landing gear mechanisms, highlighting their crucial role in high-stakes environments. Additionally, medical equipment manufacturers utilize bellow covers to guard sensitive devices from contamination, ensuring patient safety.

Conclusion

In conclusion, accordion bellow covers are an indispensable component of modern machinery and equipment. Their design versatility, along with their protective capabilities, makes them essential in various industries. From automotive to aerospace, these innovative covers enhance the functionality and durability of crucial machinery. By investing in quality accordion bellow covers, companies can significantly extend the operational life of their equipment, reduce maintenance costs, and improve overall safety. As industries continue to evolve, the demand for effective protective solutions like accordion bellow covers is likely to grow, underscoring their importance in the technological landscape.