Accordion Style Cover Design for Enhanced Visual Appeal and Functionality

The Versatility and Elegance of Accordion Bellow Covers

In the realm of machinery and equipment, protecting delicate components from dust, debris, and mechanical wear is of paramount importance. One of the unsung heroes in this protective endeavor is the accordion bellow cover. These flexible covers, designed to shield various components, are a perfect blend of functionality and elegance, making them indispensable in numerous applications across different industries.

Understanding Accordion Bellow Covers

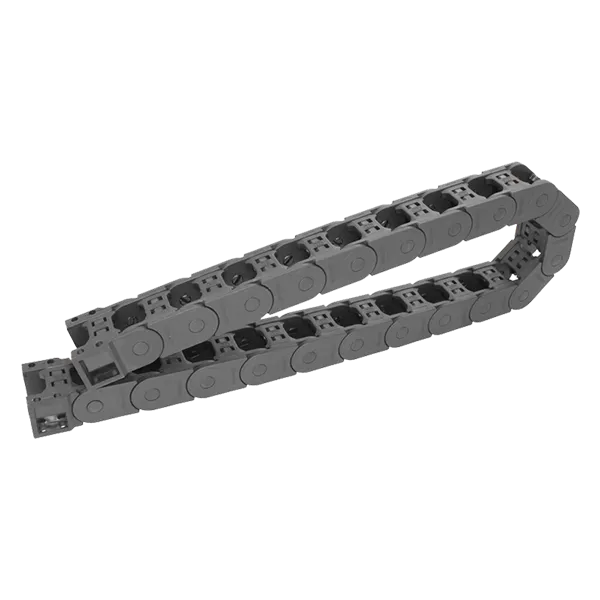

Accordion bellow covers, also known as accordion-type bellows or simply bellows, are flexible, foldable covers that can extend and contract. They are primarily constructed from materials such as rubber, fabric, or plastic, designed to endure harsh environments while providing robust protection. The distinctive accordion-like design not only allows for substantial movement but also offers excellent resilience against physical wear and moisture intrusion.

Applications Across Industries

The versatility of accordion bellow covers means they can be found in several industries, ranging from manufacturing and automotive to packaging and food processing. In manufacturing, these covers protect numerous moving parts on machinery, such as linear guides, ball screws, and telescopic arms. By preventing contamination from dirt, chips, and other particulates, they contribute significantly to the longevity and efficiency of the equipment.

In the automotive industry, accordion bellow covers are commonly used in steering mechanisms, drive shafts, and suspensions. Here, they prevent foreign objects from entering sensitive areas, minimizing the risk of mechanical failure. Likewise, in the food processing sector, these covers help maintain hygiene standards by keeping contaminants away from essential machinery, ensuring the products remain safe for consumption.

Importance of Material Selection

Choosing the right material for accordion bellow covers is crucial, as it directly impacts their performance and lifespan

. Common materials includeaccordion bellow cover

1. Rubber Known for its durability and flexibility, rubber bellow covers can withstand extreme temperatures and harsh environmental conditions. 2. Polyurethane This synthetic material offers excellent abrasion resistance and can endure a wide temperature range, making it ideal for demanding applications. 3. Fabric Often used when lightweight yet strong covers are needed, fabric bellows can also be treated to improve water resistance.

The selection depends on the specific application and environmental factors, such as temperature, moisture, and the type of contaminants involved.

Customization and Aesthetics

One of the remarkable aspects of accordion bellow covers is their ability to be customized according to the specific needs of a client or application. Manufacturers can tailor the size, shape, and even the color of the bellow covers, ensuring they fit perfectly and meet aesthetic preferences. This level of customization not only enhances functionality but can also contribute to the overall design of the machinery, ensuring that even when functional, the equipment looks visually appealing.

Maintenance and Longevity

To ensure the effectiveness of accordion bellow covers, regular maintenance is essential. This can include periodic inspections for signs of wear and tear, cleaning to remove accumulated dust and debris, and timely replacements when necessary. Well-maintained bellows can significantly extend the life of the machinery they protect, ultimately leading to cost savings for businesses through reduced downtime and lower replacement costs.

Conclusion

Accordion bellow covers may not be the most glamorous component of machinery, but their role in protecting essential parts is invaluable. With their unique design, versatility across industries, and ability to be customized, they embody a remarkable blend of functionality and elegance. As industries continue to evolve and seek efficient, reliable solutions, the importance of accordion bellow covers will only grow. Implementing these protective solutions is not merely a matter of maintenance; it is a crucial investment in the longevity and productivity of machinery and equipment. In a world that often overlooks the minor details, the accordion bellow cover stands out as a testament to the power of thoughtful design and engineering.