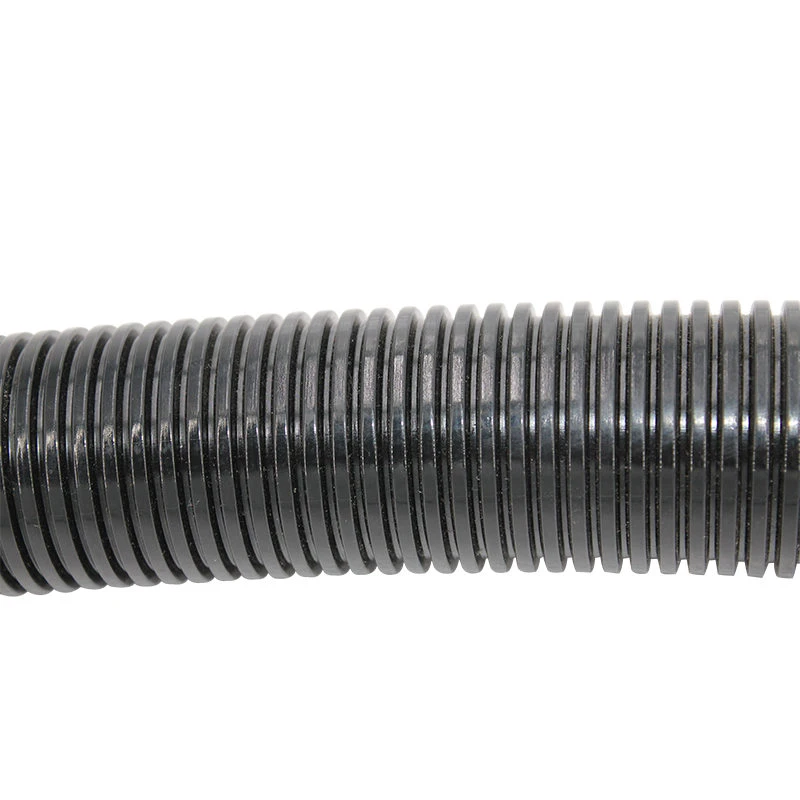

reinforced drag chain

In the realm of cable management solutions, the 8mm drag chain stands as a vital component with diverse applications across various industries. Its modest size is deceptive, concealing a powerhouse of utility and efficiency that meets the stringent demands of modern mechanical engineering and automation processes.

From an authoritative standpoint, the standards governing the production and use of drag chains, such as DIN 53516 for wear resistance and ISO 1798 for impact strength, ensure that the 8mm drag chain not only meets but often exceeds industry expectations. Manufacturers subject these components to rigorous testing, simulating real-world strain to guarantee that end-users can trust their performance under any circumstances. Trust in the 8mm drag chain extends beyond its physical attributes into its financial implications. Cost-effectiveness plays a vital role in its widespread adoption. Not only does it offer a relatively low initial investment, but its enduring durability also translates into significant savings over time. Companies benefit from less frequent replacements and lower risk of cable damage, which in turn conserves operational budgets and resources. The user experience, another critical measure of its trustworthiness, cannot be overstated. Installing an 8mm drag chain is generally straightforward, even for those with limited technical expertise. Clear instructions accompany most models, and the modular nature ensures that adjustments or extensions can be made with basic tools. For engineers and technicians, the simplicity and reliability of these drag chains reduce the technological burden and allow them to focus on optimizing other aspects of their systems. Maintaining the trust that industries place in the 8mm drag chain requires ongoing innovation. Manufacturers are continuously exploring enhancements in materials technology and design ergonomics to keep pace with the evolving demands of modern automation. Smart drag chains, with embedded sensors for monitoring and predictive maintenance, are on the horizon, promising even greater efficiencies and insights. In a digital age where every component of machinery is scrutinized for efficiency and reliability, the 8mm drag chain remains a paragon of performance excellence. It brings together unparalleled expertise in engineering, authoritative manufacturing standards, and firsthand user experience to provide a trusted solution that propels industries into the future of automation and beyond. Whether for a cutting-edge robotics lab or a bustling automotive plant, the 8mm drag chain has proven itself an indispensable asset, elevating not only cables but the very standards of industrial productivity.

From an authoritative standpoint, the standards governing the production and use of drag chains, such as DIN 53516 for wear resistance and ISO 1798 for impact strength, ensure that the 8mm drag chain not only meets but often exceeds industry expectations. Manufacturers subject these components to rigorous testing, simulating real-world strain to guarantee that end-users can trust their performance under any circumstances. Trust in the 8mm drag chain extends beyond its physical attributes into its financial implications. Cost-effectiveness plays a vital role in its widespread adoption. Not only does it offer a relatively low initial investment, but its enduring durability also translates into significant savings over time. Companies benefit from less frequent replacements and lower risk of cable damage, which in turn conserves operational budgets and resources. The user experience, another critical measure of its trustworthiness, cannot be overstated. Installing an 8mm drag chain is generally straightforward, even for those with limited technical expertise. Clear instructions accompany most models, and the modular nature ensures that adjustments or extensions can be made with basic tools. For engineers and technicians, the simplicity and reliability of these drag chains reduce the technological burden and allow them to focus on optimizing other aspects of their systems. Maintaining the trust that industries place in the 8mm drag chain requires ongoing innovation. Manufacturers are continuously exploring enhancements in materials technology and design ergonomics to keep pace with the evolving demands of modern automation. Smart drag chains, with embedded sensors for monitoring and predictive maintenance, are on the horizon, promising even greater efficiencies and insights. In a digital age where every component of machinery is scrutinized for efficiency and reliability, the 8mm drag chain remains a paragon of performance excellence. It brings together unparalleled expertise in engineering, authoritative manufacturing standards, and firsthand user experience to provide a trusted solution that propels industries into the future of automation and beyond. Whether for a cutting-edge robotics lab or a bustling automotive plant, the 8mm drag chain has proven itself an indispensable asset, elevating not only cables but the very standards of industrial productivity.