Alternative Solutions for Managing Cables with 3% and 208% Split Looms

Understanding 3%, 208%, and Split Loom A Comprehensive Overview

In the intricate world of technology and manufacturing, understanding various components and materials is essential for efficiency and functionality. Among many specialized products, two concepts that stand out are 3%, 208%, and split loom. Each term plays a pivotal role in specific applications, especially within the realms of electrical wiring and industrial design. This article aims to elucidate these terms and their relevance in contemporary practices.

What is Split Loom?

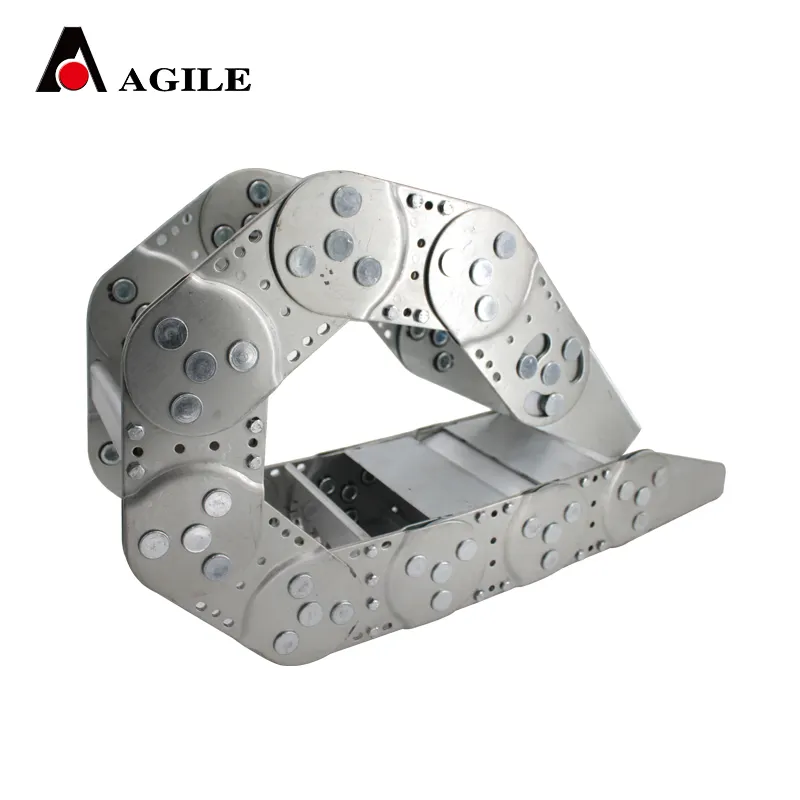

Split loom refers to a type of protective tubing used mainly in the organization and safeguarding of electrical wires and cables. This flexible plastic tubing is designed with a split along its length, allowing for easy insertion of wires while providing protection against abrasion, moisture, and other environmental hazards. Split loom is particularly valued in automotive, industrial, and commercial applications where multiple wires are bundled together.

The versatility of split loom comes from its ability to accommodate different types and sizes of wiring. It can handle anything from automotive harnesses to more extensive electrical setups. When paired with wire ties or clips, split loom not only protects wires but also helps maintain a tidy appearance, reducing the risk of wear from movement and contact with other surfaces.

Deciphering the Percentages 3% and 208%

While split loom is relatively straightforward, the numbers 3% and 208% may require further explanation, especially as they pertain to specific standards or measurements in engineering and manufacturing contexts.

3 8 split loom

The 3% figure often relates to a margin of error in design specifications, particularly in the fields of engineering and manufacturing. For example, when calculating tolerances for components, a 3% deviation might be deemed acceptable. This flexibility allows for minor variances in production that can occur due to machinery or material inconsistencies.

On the other hand, the 208% figure is less common but can imply a measure of efficiency or output in a given context. In certain industries, achieving a target that exceeds the baseline—such as productivity or energy efficiency—by 208% is a clear indicator of success and optimal performance. These percentages signify not just numbers but the striving for excellence and continuous improvement within production cycles.

The Interplay of Split Loom, 3%, and 208%

The connection between split loom, 3%, and 208% lies in their application in design efficiency and safety. When engineers and designers incorporate split loom into their wiring solutions, they often aim for optimal performance with minimal risk. Utilizing a 3% margin for error ensures that the systems they design will function reliably, while pushing towards a 208% efficiency benchmark pushes innovation.

In practice, the integration of split loom with accurate measurements leads to safer and more efficient installations. Engineers can guarantee that wiring systems are not only safeguarded against damage but also optimized for use in a variety of challenging environments, thereby enhancing the overall project quality.

Conclusion

In the dynamic landscape of technology and engineering, understanding elements like split loom, and the implications of measurements like 3% and 208%, can significantly enhance project execution. As industries continue to evolve, the importance of protective components and precise specifications cannot be overstated. By staying informed about these concepts, professionals can deliver better, safer, and more efficient solutions across various fields.