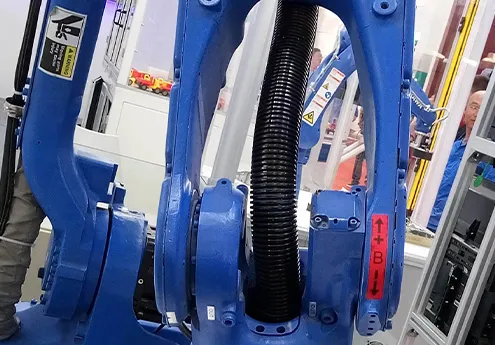

3 4 split wire loom tubing

The Versatility and Utility of 3% and 4% Split Wire Loom Tubing

In an era where efficient organization and protection of electrical wires have become paramount, split wire loom tubing has emerged as an invaluable solution for both professional electricians and DIY enthusiasts. Among the various types available in the market, 3% and 4% split wire loom tubing stand out for their unique benefits and versatility.

What is Split Wire Loom Tubing?

Split wire loom tubing is a conduit designed to protect bundles of electrical wires from abrasion, heat, and other environmental factors. Its hallmark feature is the split along its length, allowing for easy insertion and subsequent removal of wires without the need for additional fittings. This significantly simplifies wire management, making it an ideal choice for various applications, from automotive wiring to industrial installations.

Benefits of 3% and 4% Split Wire Loom Tubing

1. Enhanced Protection The primary function of split wire loom tubing is to safeguard wires from potential damage. Both 3% and 4% options provide a robust barrier that resists abrasion and cuts, which is especially important in settings where wires may rub against hard surfaces or other materials. This protective feature extends the lifespan of the wiring, reduces the risk of shorts, and enhances overall safety.

3 4 split wire loom tubing

2. Easy Installation One of the standout features of split wire loom tubing is its user-friendly design. The split allows for easy feeding of wires into the tubing. The 3% and 4% options provide varying thicknesses, making them suitable for different wire gauges. This flexibility not only saves time during installation but also allows for adjustments based on project requirements.

3. Organizational Clarity Organizing wires can be a daunting task, especially in complex installations with numerous connections. Using split wire loom tubing helps in neatly bundling wires together, reducing visual clutter and making troubleshooting easier. This is particularly beneficial in automotive and machinery applications where clarity in wiring can significantly reduce maintenance time.

4. Versatility in Application 3% and 4% split wire loom tubing can be used in diverse environments, including automotive, home improvement, marine, and industrial applications. The 3% option is typically more apt for lighter duty applications, while the 4% variant offers additional strength for heavier, more demanding tasks. This versatility means users can choose the appropriate thickness based on the specific nature of their project.

5. Heat and Chemical Resistance Both types of split wire loom tubing are often designed to withstand exposure to heat and chemicals. This resistance is critical in environments such as automotive engines or industrial settings where wires may come into contact with oils, solvents, or extreme temperatures. By using suitable tubing, one can greatly enhance the durability of the wiring system.

Conclusion

In summary, 3% and 4% split wire loom tubing are essential tools for anyone looking to secure and organize electrical wires effectively. Their protective qualities, ease of installation, and versatility make them a top choice in various industries. Whether you are a seasoned professional or a novice DIYer, investing in high-quality split wire loom tubing can lead to safer, more efficient, and organized wiring solutions. With the right choice of tubing, you can ensure that your electrical installations not only meet safety standards but also perform optimally for years to come. As technology continues to evolve, the role of such products will only become more significant, making them a crucial part of any wiring project.