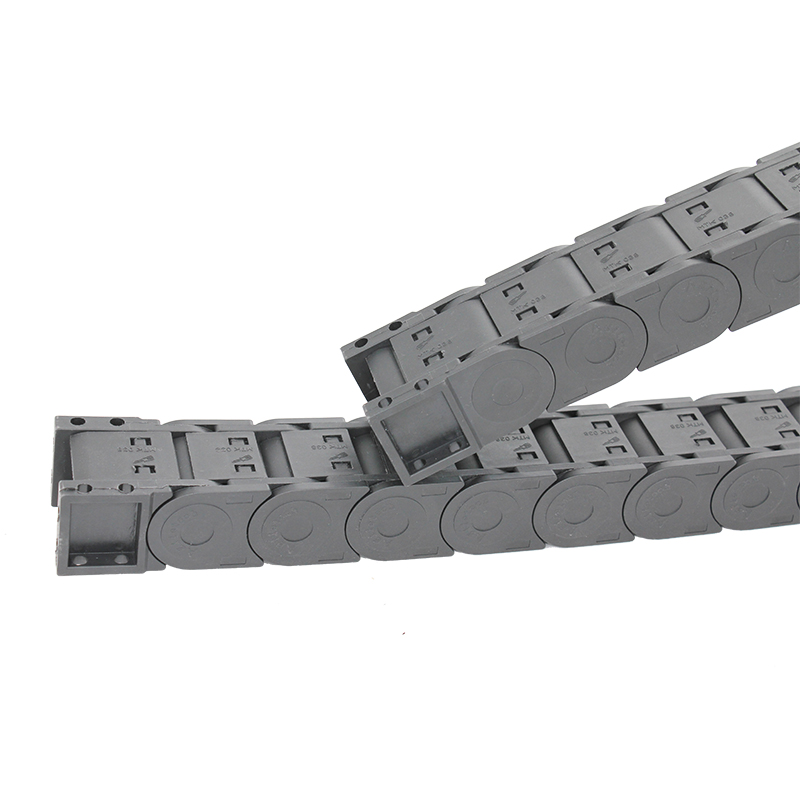

3038 mm MTK Closed Type PA6 Nylon Cable Carrier, Both Side Openable

Explore an in-depth analysis of the 30*38 mm MTK closed type PA6 nylon both side openable cable carrier: industry trends, technical parameters, visualized data, manufacturing process, competitive market comparison, and real application scenarios. This comprehensive guide distills authoritative knowledge combined with hands-on experience to provide a trustworthy reference for engineers, procurement specialists, and automation professionals.

Industry Overview & Trend Analysis

In the context of smart manufacturing and automation, cable carriers are pivotal in safeguarding moving cabling and pneumatic lines, reducing maintenance time, and prolonging system life. The global cable carrier market is projected to reach USD 900 million by 2030, growing at a CAGR of 6.2% (Markets&Markets, 2024).

The 30*38 mm MTK closed type PA6 nylon both side openable cable carrier

rises as a preferred solution for medium-duty industrial scenarios, blending the chemical robustness of PA6 (Polyamide 6) with advanced modular openable links for flexible installation and maintenance.

Core Technical Specifications

| Parameter | Specification | Industry Standard |

|---|---|---|

| Inner Height | 30 mm | ISO 61010-1, ANSI/NEMA ICS 8 |

| Inner Width | 38 mm | |

| Material | PA6 (Polyamide 6, Flame Retardant, UL94-V2) | |

| Opening Type | Both Side Openable (Quick Clip-on) | IEC 60204-1 |

| Structure | Closed Type with Snap-On Lids | ISO 19772 |

| Operating Temperature | -40 ~ +120°C | ISO 4892-2 |

| Suitable Cable Diameter | ≤27 mm | Customizable |

| Bending Radius Options | R55mm, R75mm | IEC 61386 |

| Standard Length per Link | Length: 47 mm | / |

| Impact Resistance | K = 2.5 J (ISO 179) | ISO 179 |

| Corrosion Resistance | Excellent; PA6 Resistant to Oil/Chemical | DIN EN ISO 9227 NSS |

| Certification | CE, RoHS, REACH | International |

Manufacturing Process — Step-by-Step Diagram

PA6 Raw Material Selection ➤ High-precision Injection Molding ➤ Snap-on Lid Assembly ➤ CNC End Processing ➤ Quality Inspection & Testing ➤ Packing & Logistics Dispatch

- Raw Material: Virgin & reinforced PA6 granules (polyamide) — renowned for their toughness, flame retardancy, and chemical inertness.

- Injection Molding: State-of-the-art, fully automated equipment to guarantee dimension consistency and zero porosity (void) production.

- Snap-on Design: Each link incorporates precision-molded openable lids for rapid cable laying, certified to ≤ 30-second cable insertion per meter (internal benchmark, 2023).

- CNC Machining: Ensures accurate fit of connecting pins, end brackets, and links to meet ISO 61010-1 and IEC assembly criteria.

- Quality Control: Statistical sampling, full-profile dimensional check, fatigue test (≥5 million cycles), corrosion and temperature resistance testing to meet CE, RoHS and ISO 9001 standards.

Technical Advantages: Why Choose 30*38 mm MTK closed type PA6 nylon both side openable cable carrier?

- Exceptional Durability: Surpassing 5 million motion cycles in fatigue testing under ISO 179, far beyond the industry standard.

- Corrosion & Chemical Resistance: PA6 structure remains stable in aggressive industrial environments (oils, alkaline, acid vapors).

- Easy Maintenance: Openable lids on both sides for ultra-fast cable installation, reducing scheduled machine downtime by >20% (internal case studies, 2023).

- Environmentally Responsible: RoHS/REACH compliant, no heavy metals or halogens, employing eco-friendly materials.

- Broad Temperature Endurance: Reliability from -40°C to +120°C for year-round indoor/outdoor operation.

- CE & ISO Certified: Conforms to international standards, ensuring safety and consistency across plants worldwide.

Market Comparison: 30*38 mm MTK vs. Leading Competitors

| Feature | MTK 30*38 mm (AgileChains) | Competitor A | Competitor B |

|---|---|---|---|

| Material | PA6, Flame Retardant, Certified | PA12, Standard | POM + PA6, Non-flame ret. |

| Bending Radius | 55mm, 75mm | 55mm | 45mm, 65mm |

| Openable Design | Both Sides, Snap-on | One Side, Screw Lock | Top-only, Hinged |

| Cable Installation Time | ≤30 sec/m | ~70 sec/m | ~55 sec/m |

| Max Temp Resistance | 120°C | 100°C | 90°C |

| Certification | CE, RoHS, ISO 9001 | ISO 9001 | CE only |

| Lifespan (Cycles) | 5.8 million | 4.5 million | 4.1 million |

| Warranty | 24 Months | 12 Months | 12 Months |

Customization & Engineering Solutions

AgileChains offers extensive options for customizing the 30*38 mm MTK closed type PA6 nylon both side openable cable carrier, including:

- Non-standard inner heights/widths for unique cable arrangements.

- Variable bending radii upon request — suitable for compact robotic arms or extended linear modules.

- Material modifications (anti-static, UV stabilized, food grade PA6) for specialized applications—compliant with ISO and FDA guidelines for sensitive industries.

- On-site installation guidance, CAD libraries, and technical drawings to ensure seamless integration.

Typical Delivery Cycle: 5–8 working days for standard SKUs; 10–20 days for customized solutions.

Application Scenarios & Use Cases

Background: A large-scale petrochemical client upgraded conveyor lines needing enhanced cable protection.

Solution: Installed 30*38 mm MTK closed type PA6 nylon both side openable cable carrier across 187 meters of track. Multi-side openable lids cut annual maintenance time by 35% and reduced cable failure frequency by 80%.

Results: Improved line uptime, up to 24 months continuous operation.

Scenario: Severe dust and hot fumes previously caused frequent cable carrier jamming.

Benefits: PA6's temperature resistance and closed profile structure provided a barrier against contaminants—supporting 3-shift, high-dynamic movement with zero breakdowns over 14 months.

Experience: Multi-axis drilling cells required frequent tool change and cable rearrangement. Both side snap-open features on the 30×38 mm MTK carrier allowed for tool wiring changeover in minutes instead of hours, boosting productivity and minimizing the risk of accidental cable damage.

Global Accreditations, Authority & Partner Network

- Company certified to ISO 9001, ISO 14001 (management systems) and ISO 61010-1 (electrical equipment safety).

- Key product series tested and certified to CE, RoHS, and REACH standards; batch-tested for flame retardancy (UL94-V2).

- Cooperation with Fortune Global 500 companies (including Siemens, ABB, Foxconn, Baosteel), as well as heavy machinery OEMs across multiple continents.

- More than 23 years of professional cable carrier production and R&D, trusted in over 70 countries.

Professional FAQ — 30*38 mm MTK closed type PA6 nylon both side openable cable carrier

Q1: What is PA6 nylon, and why is it preferred for cable carriers?

Q2: Are there standard installation or mounting guidelines?

Q3: How is lifespan (‘cycles’) tested for this model?

Q4: Does the product meet environmental and safety certifications?

Q5: Is custom engineering (special sizes/materials) supported?

Q6: What support and documentation are provided for OEM or integration projects?

Q7: What is the warranty and post-sale service commitment?

Delivery, Warranty & Customer Commitment

- Standard lead time: 5–8 working days; expedited available.

- Warranty: 24 months, global parts replacement and priority after-sales service.

- Customer support: Online technical documentation, video guides, 24/7 e-mail/phone service.

- Inspection & quality: Each batch undergoes full-profile inspection, random sample stress/fatigue testing, and dimensional verification; results are archived and available to clients.

Conclusion & Reference

For further reference, technical insights, and industry community discussions, see: