1 Percent and 208 Percent Split Loom for Improved Cable Management Solutions

Understanding the 1 8 Split Loom A Comprehensive Guide

In the world of electrical installation and cable management, the term split loom is frequently encountered. The 1 8 Split Loom specifically refers to a variety of split loom tubing that is used to protect and organize electrical wires and cables. This article explores the advantages and applications of split loom, particularly focusing on the 1 8 variant, its specifications, and the importance of proper cable management.

What is Split Loom?

Split loom tubing is a flexible protective conduit designed to encase and organize wires and cables. It is typically made from polypropylene or polyethylene, which provides excellent durability and resistance to various environmental factors such as abrasion, heat, and chemicals. The unique split design allows easy insertion and removal of cables without the need for additional tools. This is particularly advantageous in applications where cables may need to be frequently accessed or modified.

The 1 8 Specification

The 1 8 Split Loom is characterized by its size and adaptability. The identifier often refers to specific measurements and material properties that are suitable for a range of applications. Typically, this type of split loom is designed to accommodate various wire sizes, making it an excellent choice for both small and large wiring projects. Its robust construction ensures that wires are protected from potential damage caused by abrasion or environmental hazards.

Advantages of Using Split Loom

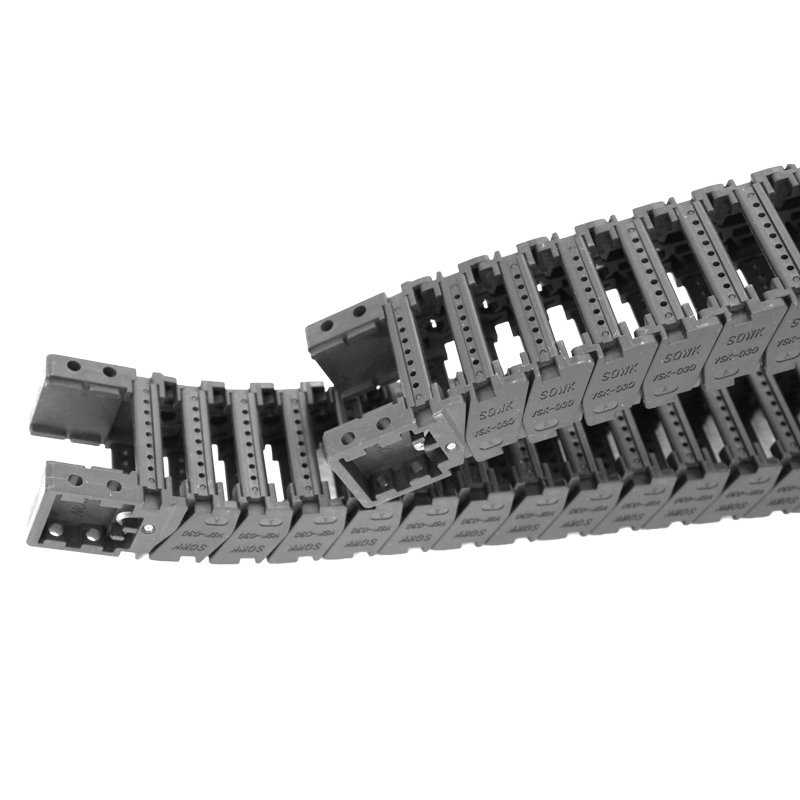

1 8 split loom

One of the most significant benefits of using split loom tubing, such as the 1 8 variant, is the enhanced organization it brings to wiring systems. By grouping cables together, split loom helps to prevent tangling and confusion, which can lead to costly installation errors. Additionally, this tubing provides a clean and professional appearance to any electrical setup, whether in automotive, industrial, or residential applications.

Another advantage is the protection it offers. Electrical wires are often exposed to harsh conditions, including UV exposure, moisture, and physical wear. The split loom acts as a barrier, safeguarding wires from damage and ensuring longevity. This protection is crucial in applications that require reliability, such as automotive wiring systems, where safety is paramount.

Applications of 1 8 Split Loom

The versatility of the 1 8 Split Loom makes it ideal for various applications. In automotive industries, it is widely used to protect wiring harnesses from heat and contamination. In industrial settings, it finds use in cable management systems that sustain demanding environments. Additionally, it is commonly employed in residential electrical installations, offering a neat and safe way to manage household wiring.

Conclusion

In summary, the 1 8 Split Loom is an essential component in the realm of cable management and protection. Its durable design, ease of use, and organizational capabilities make it invaluable across many industries. As technology continues to evolve, the importance of effective cable management and the use of reliable materials like split loom will remain ever vital for ensuring safe and efficient electrical installations.