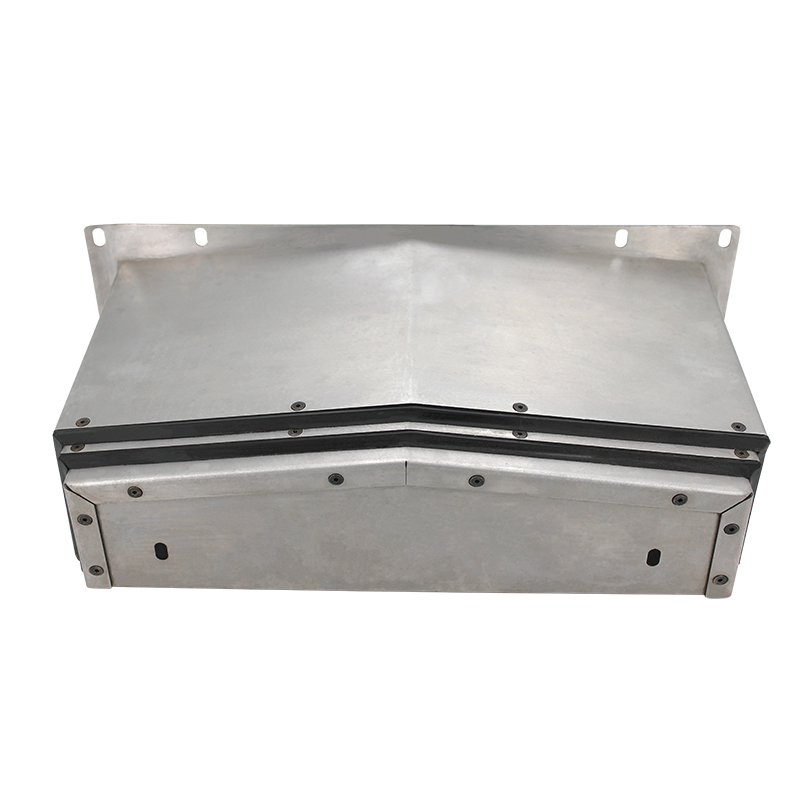

1 8 inch wire loom

The Versatility of 1 8 Inch Wire Loom

Wire loom is an essential component in the realm of electrical wiring and organization, especially in various industries such as automotive, aerospace, and construction. Among the different types of wire looms available, the 1 8 inch wire loom stands out for its versatility and efficiency in protecting and managing electrical wires.

Understanding Wire Loom

Wire loom is designed to protect and manage wires, preventing them from being damaged due to abrasion, heat, or environmental factors. Often made from durable materials like polyethylene, Nylon, or PVC, wire loom offers a reliable means to group wires together, ensuring they remain tidy and organized. The specific dimensions, such as the 1 8 inch size, refer to the diameter and layout of the wire loom, influencing its application and effectiveness.

Features of 1 8 Inch Wire Loom

The 1 8 inch wire loom has a unique diameter that makes it particularly suitable for a range of wire sizes and applications. Its flexibility allows it to accommodate multiple wires, often necessary in installations where space is limited. This size is ideal for automotive wiring, where the protection of wires within confined spaces is crucial. Furthermore, the lightweight nature of this wire loom makes it easy to handle and install, reducing labor efforts and time during the wiring process.

One of the standout features of this wire loom is its resistance to extreme temperatures and chemicals. This property is particularly important in industries where wires are exposed to harsh environments. Whether it’s exposure to oil in automotive applications or extreme temperatures in aerospace settings, the 1 8 inch wire loom provides reliable protection.

Applications in Various Industries

1 8 inch wire loom

1. Automotive Industry The automotive sector extensively uses the 1 8 inch wire loom for wiring harnesses. It helps keep the wires organized, reduces the risk of wear and tear, and provides a polished look to vehicle interiors.

2. Aerospace In aerospace applications, where safety and reliability are paramount, this wire loom serves as a protective barrier against environmental hazards. It keeps electrical systems intact, ensuring the safety of operations during flights.

3. Construction Electrical contractors frequently utilize this wire loom in residential and commercial buildings. By grouping wires together and protecting them from damage, it contributes to the overall safety and functionality of electrical systems in homes and offices.

Installation and Maintenance

Installing the 1 8 inch wire loom is a straightforward process. It can be cut to desired lengths, making it adaptable for different applications. While some types come with a split design for easy wire insertion, others may require manual feeding of wires into the loom. Proper installation not only enhances the aesthetics of wiring systems but also minimizes the risk of electrical faults.

Maintenance of wire loom involves regular inspections to check for wear and tear. As with any material, exposure to UV rays, extreme temperatures, and harsh chemicals can impact the durability of the loom. Replacing damaged sections promptly can prevent more extensive issues down the line.

Conclusion

The 1 8 inch wire loom exemplifies the perfect fusion of flexibility, durability, and functionality. Its application across various industries underlines its importance in wire management and protection. As technology continues to evolve, so too will the designs and materials used in wire looms, ensuring that they remain an integral part of electrical systems for years to come. Whether you are an engineer, a technician, or a DIY enthusiast, understanding and utilizing wire loom can significantly enhance the quality and safety of electrical installations.