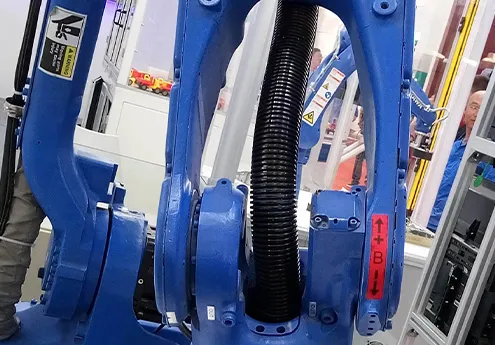

1.5 split wire loom

Understanding 1.5% Split Wire Loom A Comprehensive Overview

In the world of wiring and cables, protective measures are paramount to ensure longevity and safety. One of the most effective solutions available in the market today is the 1.5% split wire loom. This practical component serves to both organize and protect wires and cables from wear and tear, environmental damage, and accidental contact. Given the increasing complexity of wiring systems in vehicles, machinery, and electronic devices, the demand for quality wire protection products like the split wire loom has surged.

What is Split Wire Loom?

At its core, split wire loom is a type of protective tubing made from durable materials, typically polyethylene or nylon. Designed with a longitudinal split running along its length, the split wire loom allows for easy installation. Users can slide multiple cables inside without the need for disconnecting them, which saves time and effort. The “1.5%” designation typically refers to the specific size or diameter of the loom, which can accommodate wires that are up to 1.5% in diameter.

Benefits of Using 1

.5% Split Wire Loom1. Protection Against Environmental Hazards One of the primary roles of split wire loom is to shield wires from damage due to environmental factors. This includes protection against UV rays, chemicals, and moisture, which can all lead to insulation breakdown over time. By encasing wiring within a split loom, the risk of corrosion and short-circuits is significantly reduced.

2. Organization In settings where multiple cables and wires are present, organization is key. The split design of the loom allows for easy bundling and management of wires, preventing tangling and complications when troubleshooting electrical systems. A well-organized wiring system aids in maintenance and repairs, minimizing downtime.

1.5 split wire loom

3. Improved Aesthetics Aside from functional benefits, using split wire loom can improve the overall appearance of a wiring installation. Neatly arranged wires held together in loom are visually appealing and contribute to a more professional look in DIY projects, automotive applications, and electronics.

4. Cost-Effectiveness Utilizing split wire loom is an economical choice. Given its durability and ability to protect wires from costly damages, using these looms can save users money in the long run. Whether in automotive contexts or in home wiring, the initial investment in split wire loom pays off when it prevents major electrical failures.

5. Versatility This product is applicable in a wide range of industries, from automotive to industrial machinery and consumer electronics. The 1.5% size can accommodate a significant variety of wire gauges, making it adaptable to numerous applications.

Installation and Use

Installing a 1.5% split wire loom is straightforward. Users can cut the loom to the desired length, ensuring it is long enough to cover the entire length of the wires they want to protect. The open side allows for easy insertion of wires, which can be done with minimal effort. For added security, users may choose to fasten the loom in place using electrical tape or zip ties, especially in high-vibration environments like automotive applications.

Conclusion

In an era where electrical systems are integral to nearly all devices and machinery, the importance of protective measures cannot be overstated. The 1.5% split wire loom emerges as an essential tool that offers protection, organization, aesthetic appeal, and cost savings. Whether you are a DIY enthusiast, an automotive technician, or a professional in the manufacturing industry, integrating split wire loom into your wiring systems can enhance safety and efficiency, ensuring that your cables and wires remain in optimal condition for years to come.