Optimizing Cable Management with 1% and 4% Split Loom Techniques for Efficiency

Understanding 1% 4% Split Loom A Comprehensive Overview

In the realm of electrical insulation and organization, split loom tubing has become a vital component for engineers, electricians, and DIY enthusiasts alike. Particularly, the 1% 4% split loom refers to a specific type of split loom that serves to safeguard and manage electrical wiring in various applications. Understanding how this product works, its benefits, and its applications can significantly enhance your wiring management strategies.

What is Split Loom?

Split loom is a flexible, tubular sheath typically made from polyethylene or other plastic materials. Its design features a split down one side, allowing for easy placement around bundles of wires. The primary purpose of split loom is to protect wires from external factors such as abrasion, moisture, and chemical exposure, thus prolonging the lifespan of electrical systems.

The Significance of the 1% 4% Split Loom

The designation “1% 4%” generally refers to the size or specifications related to the thickness or specific percentages of the materials involved in the split loom’s construction. When discussing electrical management, these statistics can be critical. A 1% thickness may indicate a particular gauge that ensures sufficient safety and insulation for low-voltage applications, while a 4% might denote a thicker or more robust option suitable for higher load conditions.

Selecting the appropriate split loom significantly influences performance and safety in electrical setups. This is especially important in automotive applications, where vibration and environmental factors put additional stress on wiring systems.

Benefits of Using 1% 4% Split Loom

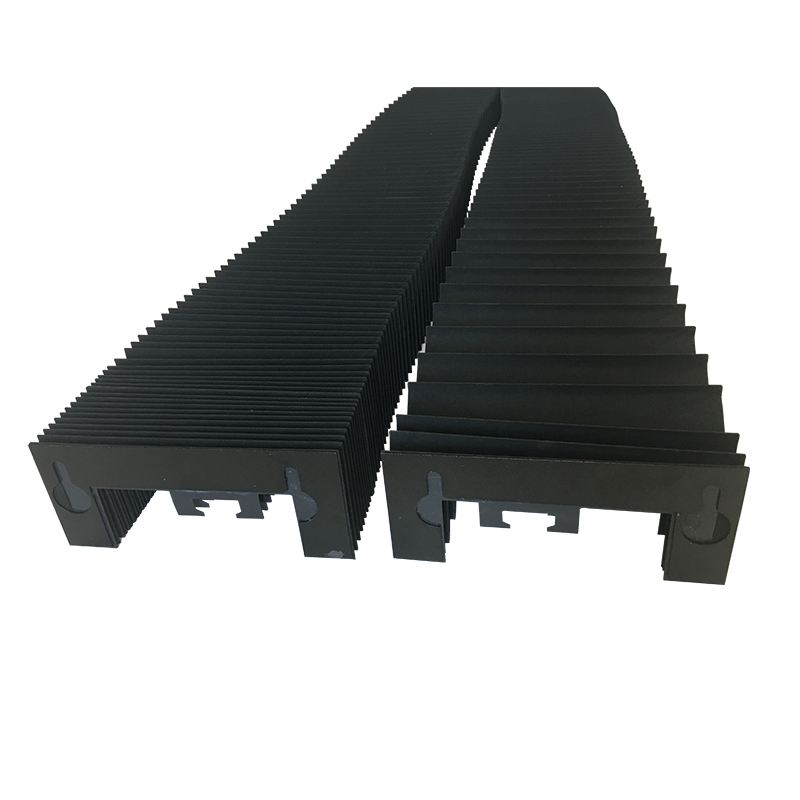

1 4 split loom

1. Protection from Physical Damage The primary advantage of using split loom tubing is its ability to shield wires from fraying and cutting caused by friction or contact with sharp objects. This is crucial in industrial settings or vehicles where wiring is exposed to various physical threats.

2. Organizational Efficiency Split loom helps to keep multiple wires bundled together, preventing tangling and confusion. This organizational aspect is especially beneficial in complex installations, as it aids in efficient troubleshooting and maintenance.

3. Flexibility and Adaptability The flexibility of the 1% 4% split loom allows it to conform to different shapes and sizes of wire bundles. This adaptability makes it suitable for a range of applications, from small electronic devices to larger automotive systems.

4. Chemical and Environmental Resistance Many split loom products are designed to resist moisture, chemicals, and UV light. This durability is particularly important in outdoor or industrial applications where exposure to harsh environments is common.

Applications

The uses of 1% 4% split loom are diverse. In automotive industries, it's used to protect wiring harnesses, ensuring that vehicles can operate safely and efficiently. In commercial and residential electrical installations, split loom organizes and protects wiring in walls, ceilings, and under floors. Moreover, in industrial settings, it is frequently employed to manage wiring in machines and equipment, safeguarding against abrasion and chemical exposure.

Conclusion

The 1% 4% split loom is a critical component for anyone involved in electrical work or equipment management. Understanding its properties and benefits can lead to safer, more organized electrical installations and maintenance. As technology advances and applications expand, the importance of effective wiring management tools like split loom only continues to grow, making it an essential item for professionals and hobbyists alike. Whether you are safeguarding wiring in a car or organizing cables in your home, investing in quality split loom can provide long-term benefits to your electrical systems.