1 4 inch split loom

Understanding 1% 204% Inch Split Loom A Comprehensive Guide

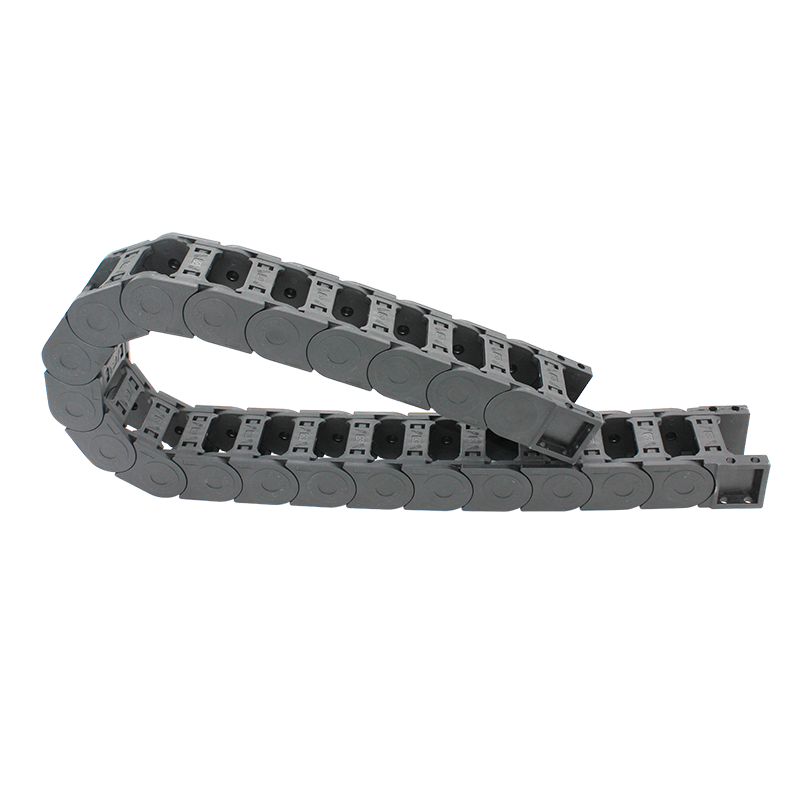

In the world of cable management and protection, the 1% 204% inch split loom is a favored choice among professionals and hobbyists alike. This innovative product offers a multitude of benefits, making it essential for various applications. In this article, we will delve into the specifics of split loom, its features, advantages, and its applications in different industries.

What is Split Loom?

Split loom tubing is a type of conduit used to organize and protect wires and cables. Made from flexible polyethylene, it features a split along its length, allowing for easy installation. The design enables wires to be simply inserted or removed, which is particularly useful in circumstances where adjustments or replacements might be necessary. The 1% 204% inch specification typically refers to the diameter of the loom, providing an effective solution for various wire sizes.

Key Features

1. Material Composition Primarily manufactured from durable polyethylene, split loom is resistant to abrasions, allowing it to protect wires from damage caused by friction. This is vital in settings where cables may rub against surfaces or each other.

2. Flexibility and Versatility The split design allows the loom to be easily wrapped around wiring, providing convenience and adaptability. This flexibility enables users to shape the loom around corners and curves without compromising the integrity or protection of the cables inside.

3. Sizes and Dimensions The 1% 204% inch measurement indicates specific sizes available in the market. These dimensions cater to various requirements, ensuring that users find the perfect fit for their cables, whether they are standard electrical wires or more specialized connections.

Advantages of Using Split Loom

1 4 inch split loom

1. Enhanced Protection One of the primary reasons for using split loom is the enhanced protection it provides to wires and cables. By organizing and shielding them, it reduces the risk of cuts, abrasions, and heat exposure.

2. Improved Aesthetics In installations where appearance matters, split loom offers a neat and organized look. The clean lines of bundled cables create a more professional environment, whether in an office, workshop, or home.

3. Ease of Installation The split design allows for a straightforward installation process. Users can easily wrap and secure the loom around their cables without the need for additional tools or complicated installation steps.

4. Cost-Effective Investing in split loom is often more cost-effective than the alternatives of using multiple types of protective coverings or conduits. It combines versatility and durability, resulting in lower overall costs in the long run.

Applications of Split Loom

The applications for 1% 204% inch split loom are vast and varied

- Automotive Industry In vehicles, it offers protection for wiring harnesses, safeguarding components against heat and abrasion. - DIY Projects Hobbyists and DIY enthusiasts utilize split loom for organizing electronics and wiring in projects, such as home automation or model building. - Industrial Settings Factories and warehouses use split loom to manage power and control cables in machinery and equipment, ensuring safety and efficiency. - Home Wiring Homeowners can benefit by using split loom in home wiring projects to protect electrical lines and enhance workflow in basements or workshops.

Conclusion

The use of 1% 204% inch split loom is a practical solution for anyone looking to protect and organize their wires and cables. Its advantages – from ease of installation to enhanced protection – make it a versatile addition to any project. As technology evolves and industries continue expanding, the demand for effective cable management solutions like split loom will undoubtedly grow, highlighting its importance in both professional and personal settings. Thus, whether you are a professional electrician or a DIY enthusiast, the split loom deserves a prominent place in your toolkit.