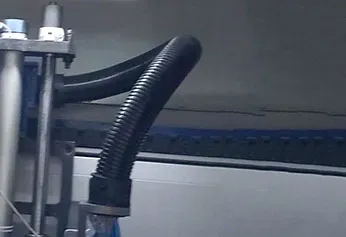

1 4 convoluted tubing

Understanding 1% 204% Convoluted Tubing A Technical Overview

In the world of engineering and manufacturing, the significance of high-performance materials cannot be overstated. Among these, convoluted tubing represents a vital component used across various industries, including automotive, aerospace, medical, and industrial applications. This article seeks to explore the concept of 1% 204% convoluted tubing, focusing on its composition, manufacturing process, advantages, and applications.

What is Convoluted Tubing?

Convoluted tubing is a type of flexible tube that features a series of grooves or convolutions, which enhance its bending capabilities while maintaining a robust structure. This unique design allows the tubing to withstand high pressures and temperatures, making it suitable for various demanding environments. The term 1% 204% refers specifically to the tubing's parameters, which typically define its composition and performance metrics.

Breakdown of the Terminology

The phrase 1% 204% can be somewhat perplexing without proper context. In many cases, it might refer to specific formulation percentage and performance metrics. 1% could denote the proportion of a particular additive or polymer that enhances the tubing's characteristics, such as its durability or resistance to certain chemicals. In contrast, 204% might reflect certain performance metrics, like flexibility, tensile strength, or expansion capabilities under specified conditions.

Materials Used

Convoluted tubing is often crafted from advanced polymer materials such as PTFE (Polytetrafluoroethylene), polyethylene, or thermoplastic elastomers. PTFE is particularly popular due to its excellent chemical resistance and ability to withstand high temperatures. The specific variations in material composition—like the 1% additive—are designed to optimize the tubing for specific applications, enhancing properties like abrasion resistance, flame retardation, or UV stability.

Manufacturing Process

The production of convoluted tubing typically involves extrusion, followed by a secondary process to create the convolutions. During extrusion, polymer materials are heated and forced through a die to create a continuous tube. The formation of the convoluted structure can be achieved through techniques like vacuum forming or by employing intricate machinery designed to impart the desired shape. Quality control is essential, ensuring that each length meets stringent industry standards for consistency and durability.

Advantages of Convoluted Tubing

1 4 convoluted tubing

The unique structure and high-performance materials of convoluted tubing offer several benefits. These include

1. Flexibility The convoluted design allows the tubing to bend and twist without kinking, essential for dynamic applications where motion is expected.

2. Chemical Resistance Materials like PTFE provide excellent protection against a wide range of chemicals, making these tubes ideal for use in laboratories and industrial environments.

3. Durability Convoluted tubing is designed to withstand harsh conditions—including extreme temperatures and pressures—extending its lifespan and reducing the need for replacements.

4. Ease of Installation The flexibility of convoluted tubing allows for easier routing and installation in complex setups, which is an advantage in confined spaces.

5. Customizability Manufacturers often offer a range of sizes, colors, and performance characteristics, allowing customers to find a solution that fits their specific needs.

Applications

The versatility of 1% 204% convoluted tubing leads to its utilization in a variety of sectors. In the automotive industry, it is used for fuel lines, air intake hoses, and brake lines. The aerospace sector employs convoluted tubing for wiring protection and fuel systems. In the medical field, it is found in breathing apparatuses, catheter systems, and fluid delivery applications.

Conclusion

1% 204% convoluted tubing is an example of how advancements in materials and engineering can lead to solutions that enhance performance in diverse applications. By understanding its composition, manufacturing process, and advantages, engineers and manufacturers can make informed decisions when selecting the appropriate materials for their specific needs. As industries continue to evolve, the demand for high-quality, flexible, and durable components like convoluted tubing is likely to grow, underscoring its importance in modern manufacturing and engineering practices.