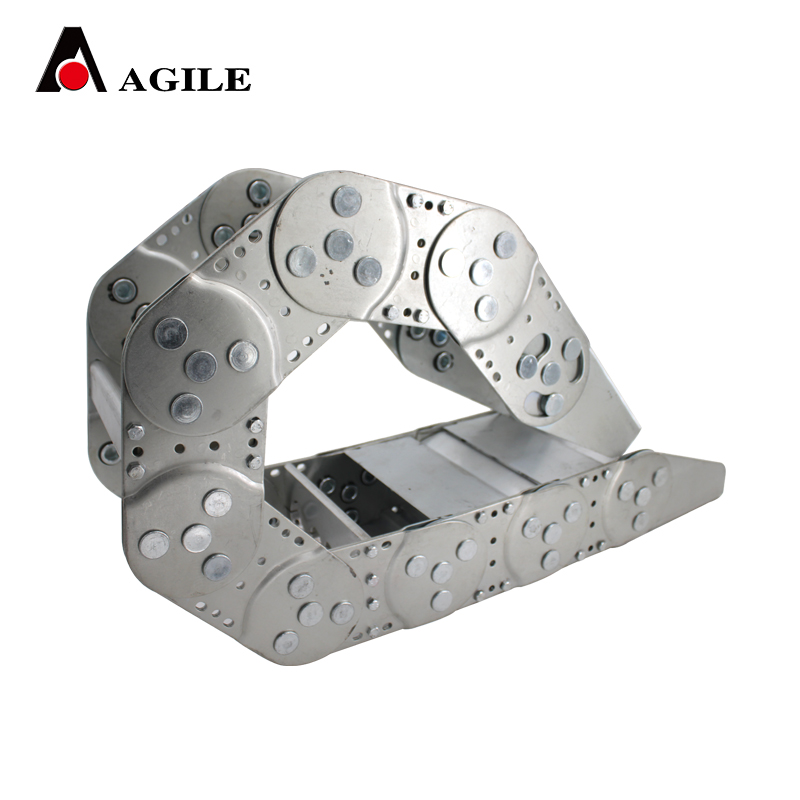

1 2 wire loom

Understanding 1% 2% Wire Looms Essentials for Efficient Wiring Solutions

Wire loom, a critical component in the field of electrical systems, plays a pivotal role in the organization and protection of wiring. When we speak of 1% and 2% wire looms, we are typically referring to the variations in material density, flexibility, and their respective applications in various industries, including automotive, industrial, and consumer electronics.

What is Wire Loom?

Wire loom is primarily a form of tubular or flexible conduit that houses and protects electrical wires. It acts as a safeguarding layer, preventing wear and tear caused by external elements, chemical exposure, and abrasion during operation. By organizing wires, wire looms streamline installations and enhance aesthetic appeal, which is particularly important in consumer-facing applications.

The Importance of 1% and 2% Wire Looms

The designation of 1% and 2% typically relates to specific performance characteristics, such as tensile strength, thermal resistance, and flexibility. For instance, in the context of materials used for wire loom, 1% wire loom may imply a lighter construction that is sufficient for low-demand applications, whereas 2% wire loom offers enhanced durability for more rigorous conditions.

1% wire loom is generally made from lightweight, flexible materials, making it ideal for applications where ease of installation and flexibility are paramount. Common uses include inside vehicles, where space is often limited, and the wiring needs to be both protected and easily accessible for maintenance.

On the other hand, 2% wire loom products tend to be constructed from sturdier materials, providing better resistance against extreme temperatures and harsh environments. These looms are particularly beneficial in industrial settings where durability is crucial, and where wires could be exposed to mechanical stress or chemical exposure.

1 2 wire loom

Applications of 1% and 2% Wire Looms

1. Automotive Industry In vehicles, wire looms are essential for organizing and protecting electrical systems. 1% wire looms might be employed in passenger cars where the wiring does not face as much environmental stress, while 2% wire looms could be utilized in heavy-duty vehicles or vehicles exposed to extreme conditions.

2. Industrial Settings Factories and manufacturing plants require reliable wiring solutions that can withstand the rigors of an industrial environment. 2% wire looms serve to protect electrical wiring from dust, moisture, and mechanical hazards, contributing to safer and more efficient operations.

3. Consumer Electronics In devices such as televisions and computers, wire looms can streamline internal layout, ensuring that wires do not tangle and are protected from wear over time. The choice between 1% and 2% loom would depend on the product's design specifications and cost considerations.

Benefits of Using Wire Loom

- Protection Wire looms provide a shield for wires against potential damage, prolonging the lifespan of electrical systems. - Organization By grouping wires together, wire looms help maintain a tidy and orderly environment, making it easier for technicians to troubleshoot or upgrade systems. - Safety Properly organized wiring reduces the risk of shorts and electrical fires, enhancing the overall safety of electrical setups.

Conclusion

In summary, both 1% and 2% wire looms play indispensable roles in the efficient management of electrical wiring across various applications. Their unique features cater to different needs within automotive, industrial, and consumer sectors, ensuring that the right balance between flexibility and durability is achieved. As technology progresses, the importance of selecting the appropriate wire loom becomes increasingly critical, underscoring the need for informed choices in electrical design and installation. Understanding these options not only aids in effective wiring management but also promotes safety and efficiency in everyday operations.