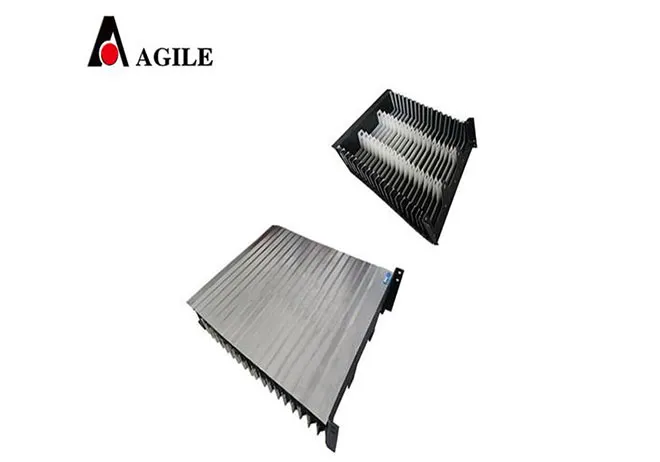

1 2 wire loom

Understanding 1% 2% Wire Looms A Comprehensive Guide

When it comes to organizing and protecting electrical wiring, wire looms have become an essential component in various industries, from automotive to home automation. Among the various types of wire looms available, the 1% and 2% wire looms stand out due to their specific use cases and advantages. This article delves into the characteristics, applications, and benefits of 1% and 2% wire looms, providing you with a detailed understanding of these crucial tools.

What is a Wire Loom?

A wire loom, also known as a wire harness or loom tubing, is a protective cover that encases electrical wires. Their primary function is to keep the wires organized, shield them from abrasion and harsh environmental conditions, and prevent electrical shorts caused by wire contact. Made from various materials such as plastic, nylon, or polypropylene, wire looms feature varying degrees of flexibility and strength, catering to different installation needs.

The Significance of 1% and 2% Wire Looms

The designations 1% and 2% generally refer to the tolerance levels applicable in the manufacturing process of wire looms or to specific dimensions and arrangements in which wiring should be laid out. Understanding these tolerances is crucial in selecting the right loom for your project, ensuring that the wires remain protected and organized, thus minimizing potential issues such as overheating or electrical failure.

1% and 2% wire looms are particularly relevant in applications where precision is vital, such as in automotive installations or sensitive electronic equipment. The specified percentage can denote certain manufacturing standards where wire bundling must be executed within tolerance levels to ensure reliable performance.

Applications of 1% and 2% Wire Looms

1. Automotive Industry In vehicles, wire looms are indispensable for managing the numerous electrical wires that connect everything from the dashboard to the engine. The 1% and 2% wire looms enable automotive engineers to ensure that wiring remains neat and does not interfere with moving parts. They help maintain compliance with safety standards while also improving the aesthetic appeal of vehicle interiors.

1 2 wire loom

2. Aerospace The aerospace sector demands high precision and reliability. 1% and 2% wire looms are critical in managing the complex wiring systems in aircraft, where failures can have catastrophic consequences. Each wire must be secured and organized meticulously to ensure safety and functionality.

3. Home Automation As smart homes become more prevalent, proper wire management is increasingly important. Wire looms assist in organizing the many wires associated with smart technology, maintaining a clean and modern look while ensuring each system's optimal performance.

Benefits of Using 1% and 2% Wire Looms

1. Protection One of the most critical benefits of wire looms is that they protect the wiring from environmental factors such as abrasion, humidity, and temperature fluctuations. This protection extends the life of the electrical systems and minimizes maintenance costs.

2. Enhanced Safety Proper organization of wiring reduces the risk of accidental short-circuits or fires, which can occur when wires are left unsecured or improperly bundled. Using 1% and 2% wire looms can greatly enhance safety in both industrial and residential electrical applications.

3. Improved Aesthetics A well-organized wiring system also looks better. Whether in a vehicle or a home, neatly arranged wires enhance the overall appearance and can even increase the resale value of the property or vehicle.

4. Ease of Access Finally, 1% and 2% wire looms allow for easier maintenance and troubleshooting. When wires are bundled and organized, electricians and technicians can quickly locate and replace faulty wires without the daunting task of sorting through an unorganized mess.

In conclusion, 1% and 2% wire looms play a vital role in ensuring efficient, safe, and visually appealing wiring in a variety of applications. Their significance in maintaining high standards of organization cannot be overstated, as they contribute to the longevity and reliability of electrical systems across industries. Investing in quality wire looms is a smart choice for anyone looking to enhance the performance and safety of their wiring projects.