Versatile 1% 2% Split Loom Tubing for Effective Cable Management Solutions

Understanding 1% 2% Split Loom Tubing A Comprehensive Guide

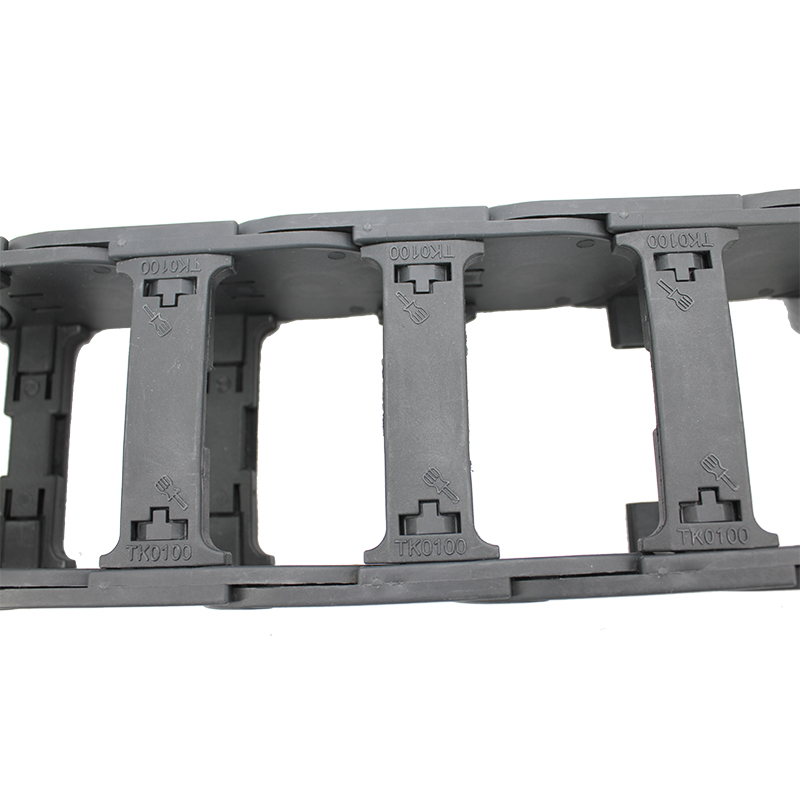

In the world of wire management and protection, split loom tubing has gained significant recognition for its durability and versatility. Split loom tubing is an excellent choice for protecting cables and wires from wear and tear, abrasion, and environmental factors. Among the various options available in the market, the 1% 2% split loom tubing category stands out for its unique attributes. This article will delve into what split loom tubing is, the specifics of the 1% 2% version, and the advantages it offers for various applications.

What is Split Loom Tubing?

Split loom tubing is a flexible, corrugated plastic tube designed for organizing and safeguarding electrical wires and cables. The design includes a split along its length, allowing for easy insertion and removal of cables without the need for expanding the tubing or disassembling the entire setup. This feature makes it especially useful in situations where wires may need to be added or removed frequently.

The 1% 2% Split Loom Tubing Explained

The terms 1% and 2% in the context of split loom tubing often refer to the wall thickness or the specific grades of the material used in the tubing’s construction. This can have significant practical implications based on the intended use.

- 1% Split Loom Tubing Generally lighter and more flexible, the 1% variant is suitable for applications where the weight of the tubing is a concern, such as in portable electronics or lightweight HVAC installations. While it provides adequate protection for low-stress environments, it may not be the best choice where high abrasion or extreme temperatures are anticipated.

- 2% Split Loom Tubing On the other hand, the 2% version is characterized by a thicker wall and improved durability. It can withstand more demanding conditions, making it ideal for industrial settings, automotive applications, and heavy machinery where cables are subjected to more physical stress. The enhanced strength of the 2% split loom makes it a go-to choice for engineers and technicians who require reliable protection in challenging environments.

1 2 split loom tubing

Advantages of 1% 2% Split Loom Tubing

1. Abrasion Resistance One of the most significant benefits of split loom tubing is its ability to protect wires from abrasion. This feature is critical in preventing damage to delicate cables, ensuring they maintain functionality over time.

2. Flexibility and Ease of Use The split design allows for easy installation and maintenance. Users can quickly add or remove wires as needed, which is a tremendous advantage in dynamic workspaces or evolving projects.

3. Cost-Effectiveness Split loom tubing is often more economical than other wire management solutions. Its durability means it can provide long-term protection, ultimately saving costs on replacements and repairs.

4. Customizable Split loom tubing comes in various colors and sizes to suit different applications. This flexibility allows for easy identification of various cables, enhancing organization and safety in complex wiring environments.

5. Environmental Protection Effective split loom tubing, especially the 2% variant, can offer protection against environmental factors such as moisture, chemicals, and UV exposure. This feature is particularly valuable in outdoor or industrial applications.

Conclusion

In summary, 1% 2% split loom tubing is an essential tool in wire management. Understanding the differences between the two variants is crucial for selecting the right tubing for your specific needs. With its protective qualities, ease of use, and cost benefits, split loom tubing significantly contributes to the efficiency and longevity of electrical installations in various industries. Whether you’re a DIY enthusiast or a professional contractor, investing in quality split loom tubing can yield significant advantages, providing safety and organization to your wiring projects.