Creating an Efficient Cable Management Solution with Split Loom for Organized Wiring

Understanding the Significance of 1% 201% 4% Split Loom

In the world of cable management and electrical safety, the term split loom might not be familiar to everyone, yet its importance is paramount. Split loom tubing is a flexible plastic conduit that protects cables from damage while also organizing them for a cleaner and safer environment. Understanding the characteristics and applications of split loom, particularly in the context of the percentages mentioned—1%, 201%, and 4%—provides valuable insight into its effective use in various industries.

What is Split Loom?

Split loom is made from durable materials, typically polyethylene or nylon, and features a split down one side. This design allows it to accommodate multiple cables or wires, providing them with a protective layer against abrasion, chemicals, and other environmental factors. The flexibility of split loom makes it easy to install, bend, and route around corners, which is particularly advantageous in applications like automotive, construction, and home wiring.

The 1%, 201%, and 4% Context

While the percentages—1%, 201%, and 4%—might initially seem arbitrary, they can serve as a metaphorical framework for understanding the role of split loom in various applications.

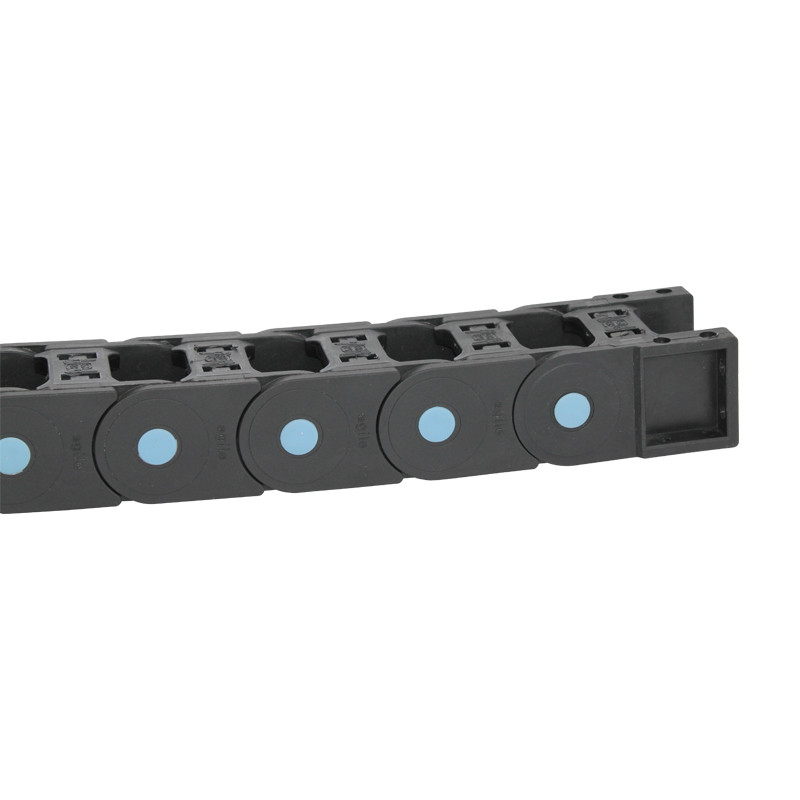

1 1 4 split loom

1. 1% – The Smallest Details Matter In any project, it's essential to pay attention to the smallest details. When managing cables, the precise choice of split loom, such as the diameter and type of material, can significantly impact the project's overall success. For example, using the correct size ensures proper fit and security, reducing the likelihood of wear and tear. Selecting the right split loom can mean the difference between a well-organized assembly and a chaotic tangle of cables that could lead to equipment failure or even safety hazards.

2. 201% – Going Beyond Expectations The 201% can be viewed as going above and beyond the basic requirements. In industries where safety and efficiency are paramount, utilizing split loom tubing effectively can enhance operations. For instance, in automotive applications, split loom not only protects electrical wiring but also contributes to the vehicle’s aesthetic by keeping wires secured and hidden away. Going beyond standard practices and implementing split loom can help in preventing costly repairs and potential hazards, illustrating how this seemingly simple product plays a crucial role in ensuring operational integrity.

3. 4% – The Final Touch of Professionalism Lastly, the 4% represents the finishing touches that elevate a project from good to exceptional. High-quality split loom, combined with careful installation techniques, makes a lasting impression. In professional environments, attention to detail reflects the quality of work being performed. A well-organized wiring system complete with split loom can enhance not only functionality but also visual appeal, leaving a positive impression on clients or stakeholders. It's these elements of professionalism that can yield repeat business and referrals.

Conclusion

In conclusion, while split loom may appear to be a simple aspect of cable management, its significance is layered and multifaceted. By considering the 1%, 201%, and 4% as representative of meticulous attention to detail, exceeding industry standards, and achieving a polished finish, we can appreciate the crucial role split loom plays in various applications. As technology continues to progress and the demands on electrical systems grow more complex, the utility of split loom will undoubtedly remain vital. It serves as a testament to how even the most unassuming components can make a tremendous difference in ensuring safety, efficiency, and professionalism in our wiring systems.