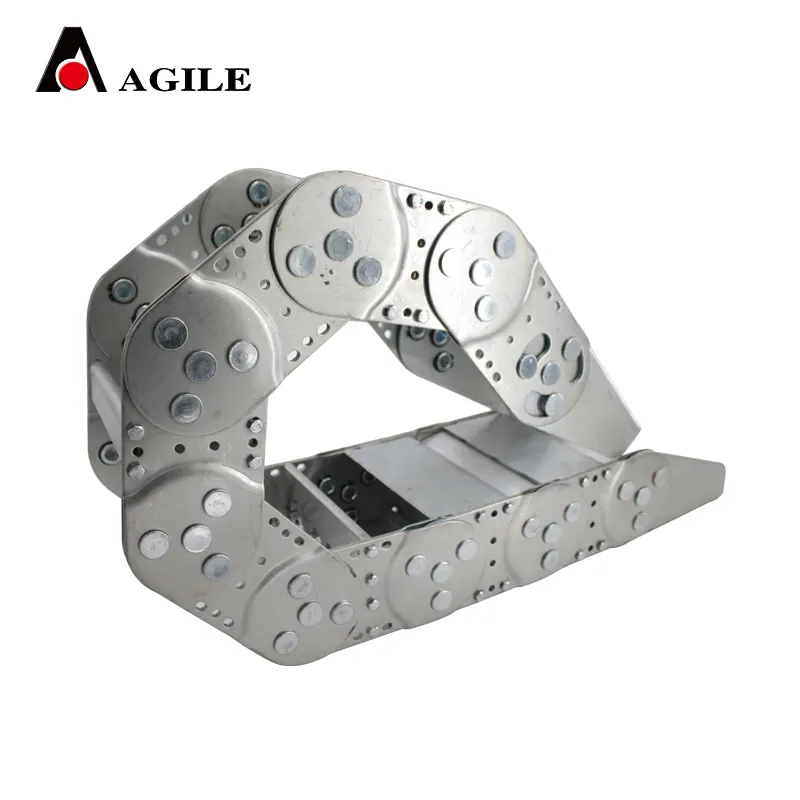

10mm drag chain

Understanding 10mm Drag Chains A Comprehensive Guide

In the world of engineering and manufacturing, the importance of effective cable management cannot be overstated. One component that has gained significant attention for its efficiency in protecting and organizing cables and hoses is the drag chain, specifically the 10mm drag chain. This article explores the features, benefits, applications, and considerations of using a 10mm drag chain in various environments.

What is a Drag Chain?

A drag chain, also known as a cable carrier or energy chain, is a device used to guide and protect flexible cables and hoses in machinery and equipment. Drag chains are designed to move along with the machine components, providing a safe pathway for electrical and fluid power lines while reducing wear and tear from movement.

Features of 10mm Drag Chains

The 10mm drag chain is characterized by its interior width of 10 millimeters, making it suitable for smaller cables and hoses. Common features include

2. Modular Design Many drag chains come in links that can be easily assembled and disassembled. This modularity allows for easy expansion or customization to fit specific applications.

3. Flexibility and Bending Radius A critical aspect of drag chains is their flexibility. The 10mm variant is designed to accommodate tight bending radii, which is essential in compact machinery or situations requiring intricate movement.

4. Low Noise Modern drag chains are designed to reduce noise levels during operation, leading to a more pleasant working environment.

Benefits of Using 10mm Drag Chains

10mm drag chain

1. Efficient Space Utilization The compact size of 10mm drag chains allows for efficient use of space within machinery, making them ideal for applications where every millimeter counts.

2. Protection Against Wear and Tear By securely routing cables and hoses, drag chains minimize friction and contact with surfaces, significantly prolonging the lifecycle of the components they protect.

3. Improved Safety By organizing cables and hoses, drag chains reduce the risk of tangling or accidental disconnection, which can lead to equipment malfunction or safety hazards.

4. Versatile Applications These drag chains are versatile and find applications in various industries, including robotics, CNC machinery, conveyor systems, and more, where reliable cable management is crucial.

Considerations When Choosing a 10mm Drag Chain

When selecting a 10mm drag chain for your application, consider the following factors

- Load Capacity Ensure that the drag chain can support the total weight of the cables and hoses it will carry. - Bending Radius Determine the minimum bending radius required for your specific application to ensure smooth operation without damaging cables.

- Environmental Conditions Assess the environmental factors such as temperature fluctuations, chemical exposure, and dust or moisture levels that could affect the drag chain’s performance.

- Cable Compatibility Verify that the cable or hose types you plan to use fit securely within the drag chain without being overly compressed.

In conclusion, the 10mm drag chain is an invaluable tool for ensuring efficient and safe cable management in various applications. Its robust design, flexibility, and ability to protect sensitive cables make it an essential component in modern machinery. By carefully considering the specific needs of your application, you can choose the right drag chain to enhance both the performance and longevity of your equipment.