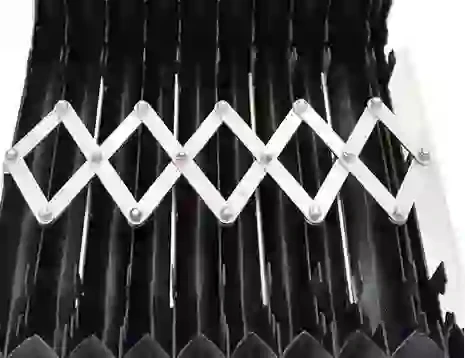

10mm drag chain

Understanding the 10mm Drag Chain A Comprehensive Insight

In the realm of industrial machinery and automation, one component that often goes overlooked yet plays a crucial role is the drag chain, specifically the 10mm drag chain. This essential device aids in cable management, ensuring that the various electrical and mechanical cables in a machine or assembly line remain organized, protected, and functional. This article will delve into the specifics of the 10mm drag chain, its applications, benefits, and maintenance considerations.

What is a 10mm Drag Chain?

A drag chain, also known as a cable carrier or energy chain, is a series of interconnected links that create a flexible conduit for cables and hoses. The “10mm” in its name refers to the width of the chain, indicating that it is designed to accommodate cables of varying sizes, particularly those with a diameter of up to 10mm. These chains are engineered to handle the rigorous demands of machinery that involve repetitive motion, such as robotic arms, CNC machines, and conveyor systems.

Key Features and Advantages

1. Space Efficiency One of the standout features of the 10mm drag chain is its compact size. With its small profile, it is able to fit into tighter spaces, making it ideal for equipment where space is at a premium.

2. Flexibility and Durability Made from high-quality materials such as nylon or polyethylene, 10mm drag chains are not only flexible but also resistant to wear and tear. This durability ensures they can withstand continuous motion and harsh environment factors, like temperature variations and exposure to chemicals.

3. Silent Operation Unlike some cable management solutions that create noise during operation, many drag chains operate silently, which is particularly beneficial in environments where noise reduction is paramount.

4. Versatile Applications The 10mm drag chain finds applications across various industries, including manufacturing, automation, robotics, and even in the medical field. They are commonly used in robotic functionalities, moving parts of machinery, and even in racing vehicles for cable management.

10mm drag chain

5. Easy Installation and Maintenance Many drag chains are designed for straightforward installation, requiring minimal tools and effort. Additionally, maintenance is simple; periodic inspections and cleaning can help in prolonging the life of the chain.

Installation and Maintenance Tips

When integrating a 10mm drag chain into machinery, it’s important to consider a few installation best practices

- Proper Sizing Ensure the drag chain is appropriately sized not only to accommodate the cables but also to allow for movement. A chain that is too small may cause friction and wear, while one that is too large could lead to clumsy cable management.

- Route Planning Plan the routing of the drag chain carefully, ensuring that there are no sharp bends or kinks that could damage the cables inside.

- Regular Inspections Conduct regular inspections to identify any signs of wear or damage. This should include checking for cracks in the chain links and ensuring that cables are properly secured within the chain.

- Lubrication Depending on the type of drag chain, periodic lubrication might be required to maintain its flexibility and functionality.

In summary, the 10mm drag chain is an invaluable component for any machinery requiring effective cable management. Its combination of space efficiency, flexibility, silent operation, and ease of installation makes it a preferred choice across numerous industries. By focusing on proper installation and maintenance practices, organizations can utilize these drag chains to maximize productivity and machine longevity. Understanding the nuances of drag chains paves the way for enhanced operational efficiency and safety in various mechanical applications.