10mm drag chain

Understanding 10mm Drag Chains A Comprehensive Guide

In today's world of automation and machinery, efficient movement and management of cables and hoses are critical for operational excellence. Among the various tools designed for this purpose, drag chains—particularly those with a 10mm width—have gained significant attention due to their practicality and functionality. This article will delve into drag chains, their advantages, applications, and what makes the 10mm variant a popular choice in various industries.

What is a Drag Chain?

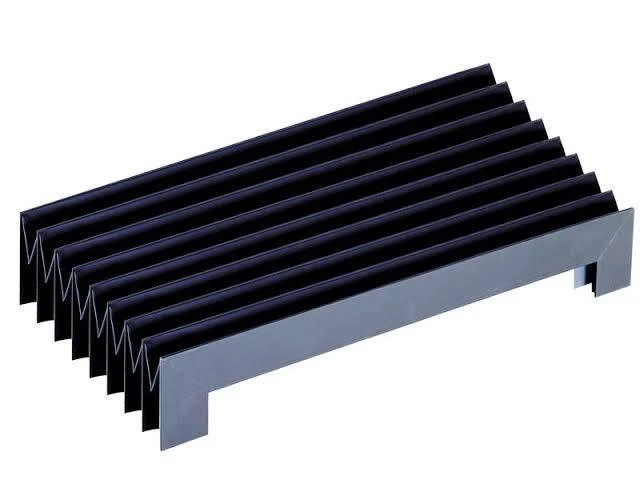

A drag chain, also known as a cable carrier or energy chain, is a type of protective guide system designed to manage and route cables and hoses in a safe and organized manner. Typically designed in a modular fashion, drag chains consist of interconnected links, allowing for flexibility in configuration. They are engineered to facilitate the movement of cables and hoses in linear, vertical, or horizontal orientations, which is crucial for machinery that have moving components.

Features of 10mm Drag Chains

The 10mm drag chain is characterized by its internal width of 10mm, making it suitable for smaller cables and hoses. The size is particularly advantageous in applications where space constraints are a concern. Here are some key features of 10mm drag chains

1. Compact Design The narrow design allows for simplified routing in confined spaces, ensuring that the installation does not interfere with other moving parts or operations.

2. Flexibility The drag chain's design allows it to bend and pivot, accommodating various motion paths while ensuring that cables and hoses remain protected.

4. Ease of Installation Designed for easy assembly and disassembly, these drag chains enable quick changes, which is essential in fast-paced production environments.

10mm drag chain

Advantages of Using 10mm Drag Chains

1. Cable Protection Drag chains provide an extra layer of protection for cables and hoses against abrasion, crushing, and entanglement. This helps extend the lifespan of your equipment and reduces downtime caused by cable replacements.

2. Improved Organization By keeping cables and hoses arranged neatly, drag chains help maintain a tidy workspace, reducing hazards and simplifying maintenance tasks.

3. Enhanced Mobility The flexible design promotes smooth movement of cables and hoses, reducing friction and wear as machinery moves.

4. Cost-Effective Solution Investing in a drag chain can be economical in the long run. By minimizing wear and preventing incidents caused by loose or tangled cables, businesses save on maintenance and replacement costs.

Applications of 10mm Drag Chains

Given their specific dimensions and advantages, 10mm drag chains find applications across a variety of sectors, including

- Industrial Automation Used extensively in robotic applications, CNC machines, and assembly lines where precise cable management is necessary for optimal performance. - Packaging Machinery Maintaining order and protecting cables in high-speed packaging machines, where the risk of tangling is high. - Entertainment Industry Employed in stage equipment and lighting systems to keep cables organized and secure while allowing for movement. - Automotive Used in manufacturing environments to manage wires in robotic arms and assembly lines.

Conclusion

In summary, 10mm drag chains play a crucial role in automating and streamlining industrial processes by providing effective cable management solutions. Their compact design, durability, and flexibility make them an ideal choice for a range of applications, ensuring that your equipment operates smoothly and efficiently. Investing in quality drag chains not only protects your cables and hoses but also contributes to a safer and more organized work environment, ultimately driving productivity and cost-efficiency.