10*15 mm MT small size mini nylon drag chain

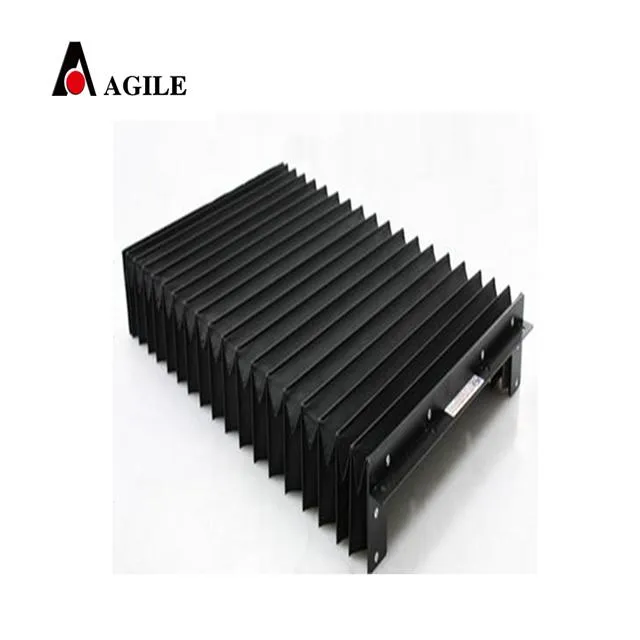

Steel drag chains have become indispensable components in various industries, playing a vital role in protecting and guiding cables, hoses, and hydraulic lines. With a remarkable blend of durability and flexibility, these chains offer an efficient solution for preventing wear and tear of cables that are subject to constant motion.

For those seeking trust in their mechanical componentry, steel drag chains stand out due to their maintenance-friendly design. Easy access for inspection and cleaning allows for longer intervals between service requirements, ultimately leading to reduced operational downtime and lower maintenance costs. This aspect is particularly crucial in high-stakes environments where any pause in production can lead to significant losses. When considering steel drag chains, it is essential to engage with a provider who possesses proven expertise in their development and application. Look for companies that offer comprehensive consultation services, helping clients choose the right chain based on load requirements, speed, and environmental conditions. Such expert guidance ensures optimal performance and alignment with overarching project goals. For practitioners considering an upgrade or new installation, case studies on steel drag chain applications can provide valuable insights. Reviewing scenarios where these chains have been successfully integrated into complex systems enables potential users to envision similar successes within their operations. Additionally, engaging with an experienced supplier who can offer customization capabilities will ensure that the chosen steel drag chain system meets both current and future needs. In conclusion, steel drag chains embody a fine balance between robust construction and flexibility, providing a trustworthy solution for cable management in challenging environments. Their development is underscored by deep industry expertise, ensuring that they continue to evolve in tandem with technological advancements. As industries strive for greater efficiency and reliability, the role of steel drag chains remains pivotal, supported by their proven effectiveness and steadfast reputation for quality and durability.

For those seeking trust in their mechanical componentry, steel drag chains stand out due to their maintenance-friendly design. Easy access for inspection and cleaning allows for longer intervals between service requirements, ultimately leading to reduced operational downtime and lower maintenance costs. This aspect is particularly crucial in high-stakes environments where any pause in production can lead to significant losses. When considering steel drag chains, it is essential to engage with a provider who possesses proven expertise in their development and application. Look for companies that offer comprehensive consultation services, helping clients choose the right chain based on load requirements, speed, and environmental conditions. Such expert guidance ensures optimal performance and alignment with overarching project goals. For practitioners considering an upgrade or new installation, case studies on steel drag chain applications can provide valuable insights. Reviewing scenarios where these chains have been successfully integrated into complex systems enables potential users to envision similar successes within their operations. Additionally, engaging with an experienced supplier who can offer customization capabilities will ensure that the chosen steel drag chain system meets both current and future needs. In conclusion, steel drag chains embody a fine balance between robust construction and flexibility, providing a trustworthy solution for cable management in challenging environments. Their development is underscored by deep industry expertise, ensuring that they continue to evolve in tandem with technological advancements. As industries strive for greater efficiency and reliability, the role of steel drag chains remains pivotal, supported by their proven effectiveness and steadfast reputation for quality and durability.