10*15 mm MT small size mini nylon drag chain

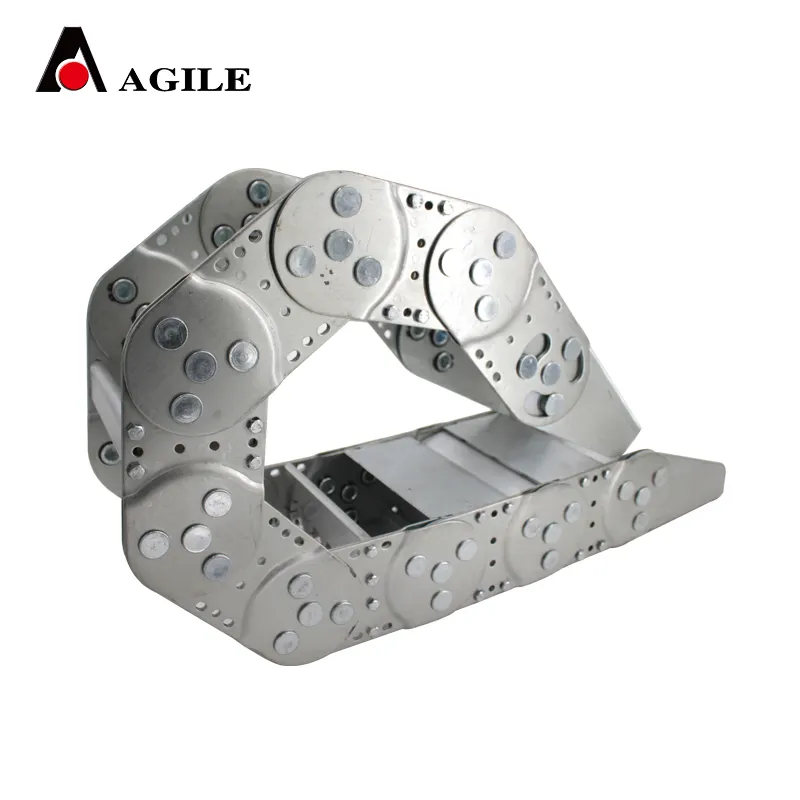

Stainless steel drag chains are garnering attention across various industries, offering a combination of durability, efficiency, and cleanliness that's hard to match. Integral to systems that require smooth operation even under tough conditions, these chains advance the concept of reliable protection and management of cables and hoses.

Trustworthiness in product quality and consistency can be assured by understanding the manufacturing protocols dedicated to these chains. Reputable manufacturers automate quality checks throughout production, focusing on consistent alloy composition and structural integrity. This rigorous quality assurance is crucial in fields like aerospace and defense, where drag chains' failure is not an option. Users frequently rely on certifications and feedback from independent testing agencies to choose their drag chain providers, a testament to the importance placed on trustworthiness. Another aspect frequently highlighted by users is the smooth installation process afforded by the modular design of stainless steel drag chains. Unlike traditional systems that may require specialized tools or skills, these chains are designed for ease of assembly and disassembly, thus promoting quick integration and modification according to specific needs. Accessibility complements trust, as industries prefer solutions that do not compromise efficiency for operational complexity. Moreover, the environmental aspect stands as a growing concern. Stainless steel is a recyclable material, aligning with the increasing corporate and social responsibility efforts to adopt sustainable practices. The lifecycle of stainless steel drag chains thus holds a positive environmental impact, reducing waste and promoting resource efficiency. In conclusion, stainless steel drag chains emerge as a formidable choice for any industry prioritizing durability, reliability, and efficiency. Their resistance to harsh conditions, coupled with an adaptable and robust construction, embodies the perfect blend of experience, expertise, authoritativeness, and trustworthiness. As technology continues to evolve, so too will the applications and innovations surrounding these indispensable components, ensuring their place in the infrastructure of modern machinery and industrial processes.

Trustworthiness in product quality and consistency can be assured by understanding the manufacturing protocols dedicated to these chains. Reputable manufacturers automate quality checks throughout production, focusing on consistent alloy composition and structural integrity. This rigorous quality assurance is crucial in fields like aerospace and defense, where drag chains' failure is not an option. Users frequently rely on certifications and feedback from independent testing agencies to choose their drag chain providers, a testament to the importance placed on trustworthiness. Another aspect frequently highlighted by users is the smooth installation process afforded by the modular design of stainless steel drag chains. Unlike traditional systems that may require specialized tools or skills, these chains are designed for ease of assembly and disassembly, thus promoting quick integration and modification according to specific needs. Accessibility complements trust, as industries prefer solutions that do not compromise efficiency for operational complexity. Moreover, the environmental aspect stands as a growing concern. Stainless steel is a recyclable material, aligning with the increasing corporate and social responsibility efforts to adopt sustainable practices. The lifecycle of stainless steel drag chains thus holds a positive environmental impact, reducing waste and promoting resource efficiency. In conclusion, stainless steel drag chains emerge as a formidable choice for any industry prioritizing durability, reliability, and efficiency. Their resistance to harsh conditions, coupled with an adaptable and robust construction, embodies the perfect blend of experience, expertise, authoritativeness, and trustworthiness. As technology continues to evolve, so too will the applications and innovations surrounding these indispensable components, ensuring their place in the infrastructure of modern machinery and industrial processes.