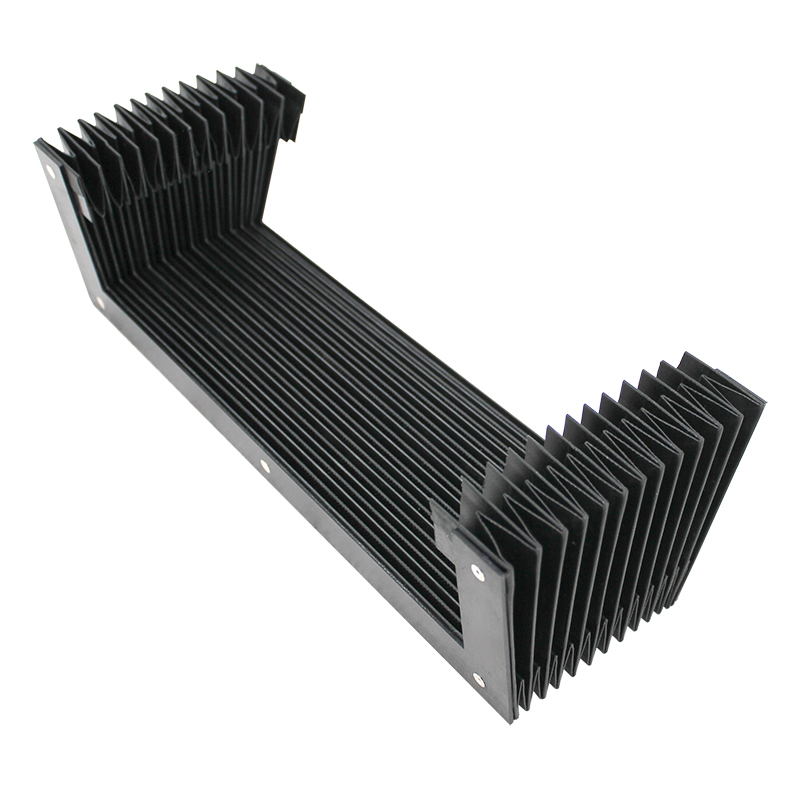

1 4 wire loom

Understanding 1% 204% Wire Loom A Comprehensive Guide

Wire looms are essential tools in the world of electrical engineering and automotive design. They serve a critical purpose in organizing and protecting wires, ensuring that electrical systems operate safely and efficiently. Within this realm, one specific category has been gaining traction the 1% 204% wire loom. This article will delve into what it is, its uses, and why it is an important component in various applications.

What is a Wire Loom?

A wire loom is a protective cover that organizes and shields electrical wires. It typically comes in various materials, including plastic and nylon, and can be found in different shapes and sizes to accommodate differing needs. Wire looms not only prevent wires from tangling or becoming damaged but also contribute to a cleaner and more professional appearance in installations.

The 1% 204% Specification

The term 1% 204% refers to specific parameters and configurations that are crucial for various applications. While it may not be a standard designation across the board, it implies a particular focus on the size, tensile strength, and utility of the wire loom. The numbers could represent various factors such as the wire’s resistance to heat, flexibility, or the percentage of the loom's effectiveness in protecting the wires inside.

Key Features and Benefits

1. Protection One of the primary advantages of using a 1% 204% wire loom is its ability to safeguard wires from abrasion, moisture, and other environmental factors. It creates a barrier that ensures wires remain intact and functional over time.

1 4 wire loom

2. Organization These wire looms make it easy to sort and manage wiring systems. In automotive and industrial applications, where multiple wires run parallel to one another, having a dedicated loom can significantly reduce confusion and improve troubleshooting efficiency.

3. Aesthetic Appeal A well-organized wiring system also looks professional and clean, which is particularly important in consumer-facing settings. When customers see neat wiring, it enhances their perception of quality and attention to detail.

4. Heat Resistance Many 1% 204% wire looms are designed to withstand higher temperatures, making them suitable for environments that experience extreme heat, such as automotive engines or industrial machinery.

5. Ease of Installation These looms are designed for user-friendliness, enabling quick installation and removal when needed. This is particularly beneficial in settings where modifications to wiring systems are common.

Applications

The use of 1% 204% wire looms spans various industries. In the automotive sector, they are employed to manage the complex wire systems found in modern vehicles, ensuring safety and reliability. In industrial settings, they help organize wiring in machinery and equipment, thereby enhancing maintenance efforts.

In conclusion, the 1% 204% wire loom is a vital tool for both electrical engineers and technicians. It not only provides essential protection for wires but also enhances organization and aesthetics in a variety of applications. As technology continues to evolve, the demand for such specialized wire management systems will likely increase, reflecting the ongoing need for efficiency, safety, and professionalism in electrical work. Whether you are involved in automotive design or electrical installations, understanding and utilizing high-quality wire looms like the 1% 204% can significantly improve your projects and operations.