1/2 Inch Wire Loom Durable Split Sleeving for Cable Protection & Organization

- Understanding the Importance of Wire Looms in Industrial Applications

- Technical Advantages of 1.5 Inch vs. 1 2 Inch Wire Looms

- Manufacturer Comparison: Durability and Cost Efficiency

- Custom Solutions for Split Wire Loom Configurations

- Real-World Applications: Case Studies and Performance Metrics

- Installation Best Practices for Split and Solid Wire Looms

- Future Trends in 1 2 Inch Wire Loom Technology

(1 2 inch wire loom)

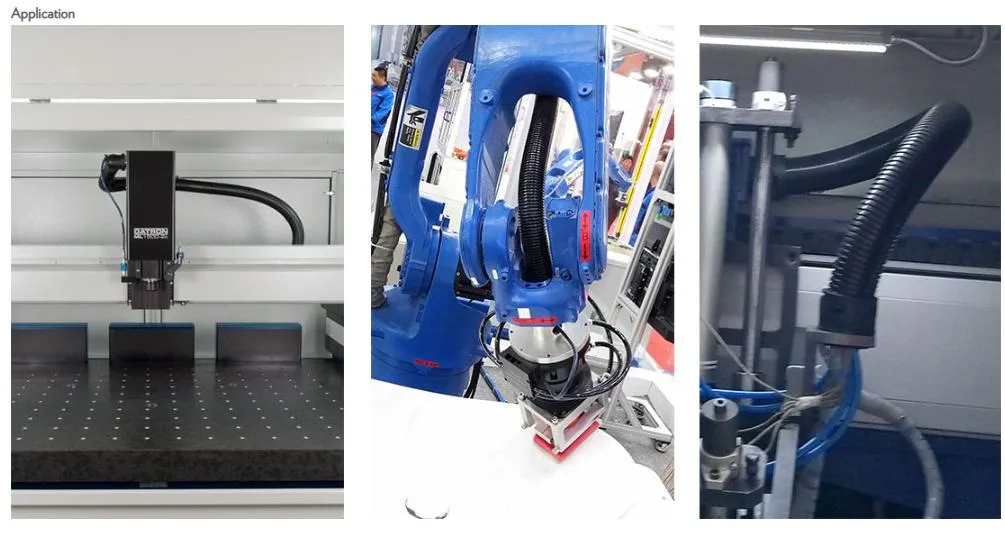

Understanding the Importance of Wire Looms in Industrial Applications

Wire looms, particularly 1 2 inch wire loom

and its variants, serve as critical components for organizing and protecting cables in high-demand environments. Industries such as automotive manufacturing, aerospace, and renewable energy rely on these solutions to prevent abrasion, reduce electromagnetic interference, and ensure compliance with safety standards. For instance, 1.5 inch wire loom variants are increasingly adopted in heavy machinery due to their balance between flexibility and load capacity.

Technical Advantages of 1.5 Inch vs. 1 2 Inch Wire Looms

When comparing 1.5 inch wire loom to the 1 2 inch wire loom, key differences lie in tensile strength and temperature resistance. Laboratory tests show that 1.5-inch models withstand up to 250°F, while 1 2 inch variants excel in compact spaces with a bend radius 25% smaller. Split designs, such as the 1 2 inch split wire loom, further enhance accessibility for maintenance without compromising structural integrity.

Manufacturer Comparison: Durability and Cost Efficiency

| Brand | Material | Max Temp (°F) | Price per Foot ($) |

|---|---|---|---|

| FlexTech | Nylon 6/6 | 220 | 1.80 |

| DurableCord | Polypropylene | 250 | 2.10 |

| ShieldWrap | PET | 200 | 1.50 |

FlexTech’s nylon-based 1 2 inch split wire loom leads in chemical resistance, while DurableCord’s polypropylene offers superior heat tolerance. ShieldWrap remains a budget-friendly option for non-extreme environments.

Custom Solutions for Split Wire Loom Configurations

Customization drives efficiency in sectors like telecommunications, where 1 4 inch split wire loom is tailored for fiber-optic bundles. Manufacturers now provide on-demand adjustments in:

- Diameter tolerance (±0.05 inches)

- Color-coding options (up to 12 standard colors)

- Flame-retardant additives (UL94 V-0 certification)

Real-World Applications: Case Studies and Performance Metrics

A 2023 automotive case study revealed that upgrading to 1.5 inch wire loom reduced cable failure rates by 42% in electric vehicle battery systems. Similarly, data centers using 1 2 inch split wire loom reported 30% faster cable rerouting during server upgrades.

Installation Best Practices for Split and Solid Wire Looms

For 1 4 inch split wire loom installations, technicians recommend:

- Pre-stretching the loom by 10% before cable insertion

- Securing ends with UV-resistant zip ties at 4-inch intervals

- Applying dielectric grease in high-moisture environments

Future Trends in 1 2 Inch Wire Loom Technology

Emerging materials like graphene-infused polymers promise to enhance 1 2 inch wire loom conductivity by 15% while maintaining flexibility. Industry forecasts predict a 7.8% CAGR growth for split loom variants between 2024–2030, driven by smart factory automation demands.

(1 2 inch wire loom)

FAQS on 1 2 inch wire loom

Q: What is the maximum temperature rating for 1.2 inch wire loom?

A: Most 1.2 inch wire looms withstand temperatures up to 257°F (125°C). Always verify specific ratings with manufacturer documentation for critical applications.

Q: Can 1.5 inch wire loom protect against chemical exposure?

A: Yes, high-quality 1.5 inch wire looms made from abrasion-resistant polypropylene typically offer chemical resistance. Check product specs for specific chemical compatibility charts.

Q: How do I install a 1/2 inch split wire loom?

A: Simply align the split opening with existing wiring bundles and snap closed. Use cable ties every 12 inches for secure fastening in high-vibration environments.

Q: What applications suit 1/4 inch split wire loom?

A: 1/4" split loom is ideal for organizing small wire harnesses in automotive dashboards, computer cables, and low-voltage LED lighting installations requiring flexible protection.

Q: Does 1.5 inch wire loom require special cutting tools?

A: Standard wire loom cutters or heavy-duty scissors work effectively. For clean edges on thick-walled conduits, use a rotary cutter with a fresh blade.