Customizing Hinge Chip Conveyors for Specific Needs

In the realm of industrial material handling, the ability to customize equipment to meet specific operational requirements is crucial. Hinge chip conveyor, hinged belt chip conveyor, and chip conveyor from Shijiazhuang Anjie Electric Co., Ltd. offer wholesalers the flexibility to provide tailored solutions to their clients.

Main Features Overview of Chip Conveyors

|

Feature Aspect |

အသေးစိတ် |

|

Conveyable Materials |

Capable of transporting iron scrap, aluminum scrap, copper scrap, and non - iron metal. Unsuitable for powder scrap. |

|

Efficiency and Speed |

High conveying efficiency with a wide range of speed options available. |

|

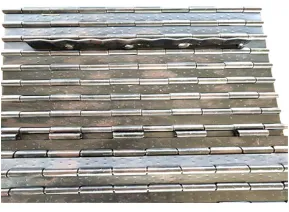

Structural Design |

Utilizes a new type of hinge plate structure connected with a spherical surface, preventing light and tiny chips from adhering to the belt. |

|

Material and Durability |

Constructed from stainless steel, with main spare parts processed for anti - abrasion and anti - corrosion properties. |

|

Functional Performance |

Stable operation, noise - free, ensuring safety and reliability during use. |

|

Appearance and Operation |

Streamline shape appearance enables smooth chip conveying. |

|

Safety Feature |

Equipped with an overload protection function. |

Customization Options for Hinge Chip Conveyor

- Material - Specific Adaptations: The hinge chip conveyor(https://www.agilechains.com/cnc-hinge-type-metal-swarf-chip-conveyor.html)from Shijiazhuang Anjie Electric Co., Ltd. can be customized based on the type of chips to be conveyed. For instance, when dealing with highly abrasive iron scrap, additional wear - resistant coatings can be applied to the conveyor's surface. In cases where the chips are corrosive, such as certain types of aluminum or copper scrap, the stainless - steel components can be further treated to enhance corrosion resistance, ensuring the hinge chip conveyor can handle the specific material without premature wear or damage.

- Size and Capacity Tailoring: Wholesalers can work with the company to customize the size and capacity of the hinge chip conveyor. Whether it's adjusting the length and width of the conveyor belt to fit into a specific industrial space or increasing the load - bearing capacity to handle larger volumes of chips, the customization allows for seamless integration into different production lines. This ensures that the hinge chip conveyorcan meet the unique throughput requirements of each client's operation.

- Speed and Control Customization: The speed of the hinge chip conveyorcan be customized according to the client's production pace. In some industries, a slower speed might be preferred for precise chip handling, while others may require a faster conveyor to keep up with high - volume production. Additionally, control systems can be customized, such as adding variable frequency drives for smooth speed adjustments or integrating sensors for automated operation, providing clients with a hinge chip conveyor that operates exactly as needed.

Operational Advantages of Hinged Belt Chip Conveyor

- Efficient Chip Handling:The hinged belt chip conveyor's unique hinge plate structure, connected with a spherical surface, offers superior chip handling capabilities. This design prevents light and tiny chips from getting stuck on the belt, ensuring a continuous and unobstructed flow of materials. Whether it's conveying small metal shavings or larger chunks of scrap, the hinged belt chip conveyor can handle the task with efficiency, reducing the risk of blockages and downtime in the production process.

- Long - Term Reliability:Thanks to its construction from stainless steel and the anti - abrasion and anti - corrosion processing of main spare parts, the hinged belt chip conveyor provides long - term reliability. It can withstand the harsh conditions of industrial environments, including exposure to moisture, chemicals, and constant mechanical stress. This durability means that clients can rely on the hinged belt chip conveyor for extended periods without the need for frequent replacements or extensive maintenance, resulting in cost savings over time.

- Quiet and Safe Operation: The hinged belt chip conveyoroperates quietly, minimizing noise pollution in the workplace. Its stable function and overload protection feature also ensure safety during operation. The overload protection mechanism automatically shuts down the conveyor when it detects excessive loads, preventing damage to the equipment and potential hazards to workers. This makes the hinged belt chip conveyor a safe and comfortable choice for industrial applications.

Application - Specific Customization for Chip Conveyor

- Industry - Driven Modifications: Different industries have specific requirements for chip conveyor In the metalworking industry, where there is a mix of various metal chips, the conveyor can be customized with stronger magnets (if applicable) to separate ferrous and non - ferrous metals during the conveying process. In the automotive manufacturing sector, where space is often at a premium, the chip conveyor can be designed with a more compact and flexible layout to fit into tight production areas, ensuring efficient chip removal without disrupting the production line.

- Environmental Considerations: For clients operating in environmentally sensitive areas or those with strict environmental regulations, the chip conveyorcan be customized to meet these requirements. This may include adding dust - collection systems to prevent airborne particles from escaping during chip conveyance or incorporating leak - proof designs to avoid any spills or contamination of the surrounding environment. By customizing the chip conveyor for environmental compliance, wholesalers can offer solutions that meet the needs of clients across different regulatory landscapes.

- Integration with Existing Systems: Many clients already have existing production systems in place. The chip conveyorcan be customized to integrate seamlessly with these systems. This could involve customizing the conveyor's input and output interfaces to match the height, width, and speed requirements of other equipment, such as machining centers or sorting machines. By ensuring compatibility, the chip conveyor can enhance the overall efficiency of the production line, working in harmony with other components to streamline the chip - handling process.

Hinge Chip Conveyor FAQS

What types of chips can the hinge chip conveyor handle?

The hinge chip conveyor can handle iron scrap, aluminum scrap, copper scrap, and other non - iron metal chips. However, it is not suitable for powder scrap due to its design and the nature of powder materials, which may cause issues with adhesion and flow.

How can the capacity of the hinged belt chip conveyor be increased?

The capacity of the hinged belt chip conveyor can be increased through customization. Shijiazhuang Anjie Electric Co., Ltd. can modify the size of the conveyor belt, such as increasing its width or length, and strengthen the structural components to handle heavier loads. Additionally, the drive system can be upgraded to provide more power for higher - volume chip conveying.

Can the chip conveyor be customized for outdoor use?

Yes, the chip conveyor can be customized for outdoor use. The company can use materials with enhanced weather resistance, such as specially coated stainless steel, and add protective enclosures to shield the conveyor from rain, sun, and other outdoor elements. These customizations ensure that the chip conveyor can operate reliably in outdoor environments.

What is the typical lifespan of a customized hinge chip conveyor?

The lifespan of a customized hinge chip conveyor depends on various factors, including the type of chips conveyed, operating conditions, and maintenance practices. However, with its high - quality materials and durable design, a well - maintained hinge chip conveyor from Shijiazhuang Anjie Electric Co., Ltd. can last for many years, providing long - term value to clients.

How does the overload protection function of the hinged belt chip conveyor work?

The hinged belt chip conveyor is equipped with sensors that monitor the load on the conveyor. When the detected load exceeds the preset limit, the overload protection function is triggered. This causes the conveyor to automatically stop, preventing damage to the conveyor belt, motor, and other components, and protecting the overall system from potential failures.