Optimizing Cable Management with 1% and 4% Split Loom Solutions for Effective Organization

Understanding 1% 4% Split Loom A Comprehensive Guide

In the world of electrical wiring and cable management, the tools and materials we use can significantly impact the efficiency and safety of our projects. One of these essential tools is known as split loom, specifically the 1% 4% split loom variety. This article aims to delve into what split loom is, its applications, the benefits it provides, and the specifics of the 1% 4% split loom type.

What is Split Loom?

Split loom is a type of plastic tubing that is designed to house and protect electrical wires and cables. It is often made from materials such as polyethylene or nylon, which provide durability and flexibility. The split refers to the longitudinal cut along the length of the loom, allowing cables to be easily inserted and removed. This feature makes split loom an excellent choice for both temporary and permanent wiring solutions.

Understanding the 1% 4% Designation

When referring to 1% 4% split loom, it is essential to understand what these percentages signify. In the context of split loom, they often denote the thickness or the percentage of the wall of the tubing in relation to its diameter. A 1% discount of the total diameter might indicate a lighter yet effective design, while the 4% version could signify a heavier-duty option better suited for more robust applications. These distinctions allow engineers and technicians to choose the right type of split loom based on the specific needs of their project, balancing flexibility, durability, and protective capabilities.

Applications of Split Loom

Split loom is utilized across various industries and for multiple applications. Here are some prominent uses

1. Automotive Wiring Split loom is commonly used in vehicles to organize and protect the myriad of wires that run throughout the body and engine. Its flexible nature allows it to withstand high temperatures and environmental factors.

2. Home and Commercial Wiring In residential and commercial settings, split loom can protect electrical wiring from abrasion, moisture, and other hazards. It helps to maintain a neat and organized appearance, reducing the risk of tangling or damage.

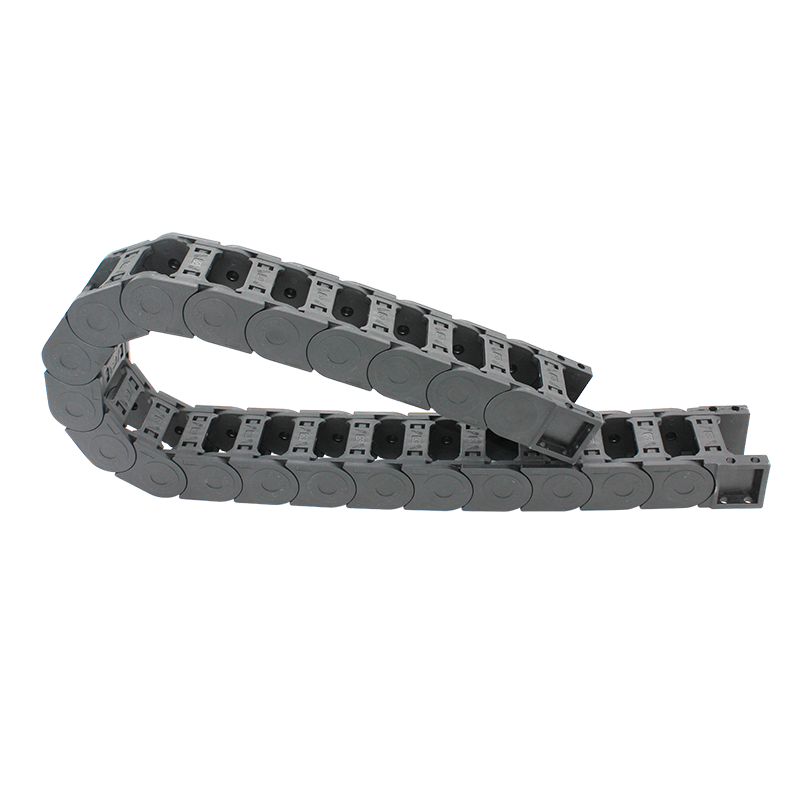

1 4 split loom

3. Industrial Equipment Manufacturing plants often use split loom to manage the extensive cabling associated with machinery and equipment. Its durability is vital in harsh environments where wires are subject to wear and tear.

4. Telecommunications In the telecommunications sector, split loom is employed to safeguard cables from electrical interference and physical damage, ensuring uninterrupted service.

Benefits of Using Split Loom

The adoption of split loom in wiring and cable management comes with several benefits

- Protection The primary benefit of using split loom is its ability to protect wires from mechanical damage, moisture, and chemicals. This prolongs the lifespan of the cables, reduces maintenance costs, and enhances safety.

- Organization Split loom helps in organizing cables, making it easier to identify, trace, and replace wires without unnecessary confusion or disruption.

- Flexibility The design of split loom allows for easy insertion and removal of cables. This flexibility is essential during installation and when adjustments or repairs are needed.

- Cost-Effectiveness Given its durability and protective benefits, using split loom can be a cost-effective solution in the long run, reducing the need for frequent replacements and repairs.

Conclusion

In summary, understanding the intricacies of 1% 4% split loom or any type of split loom technology is crucial for anyone working with electrical systems. Whether in automotive, residential, industrial, or telecommunications applications, the benefits of using split loom are undeniable. Its protection, organization, and flexibility make it an indispensable tool in the arsenal of engineers and technicians alike. As technology evolves, so too will our methods of cable management, but split loom remains a steadfast choice for reliable and effective wiring solutions.