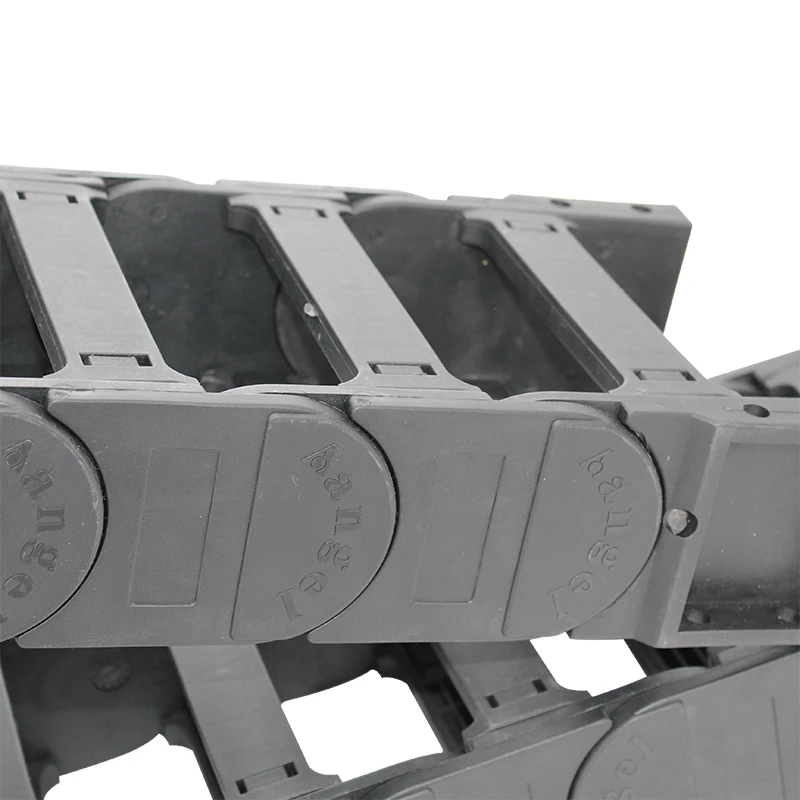

cps drag chain

Understanding CPS Drag Chains A Comprehensive Guide

In the world of engineering and automation, the functionality and reliability of machinery are paramount. One essential component that plays a vital role in enhancing these attributes is the drag chain, specifically the CPS (Cable Protection System) drag chain. This article will explore the significance of CPS drag chains, their advantages, applications, and how they contribute to optimizing industrial operations.

What is a CPS Drag Chain?

CPS drag chains are mechanical systems designed to manage moving cables and hoses in various machinery. These chains provide protection and organization, ensuring that cables are not subjected to wear and tear or tangling, which can lead to significant downtime and increased maintenance costs. The CPS designation emphasizes the system's role in safeguarding cables against mechanical stress, dirt, and other environmental factors that could lead to failure.

Advantages of CPS Drag Chains

1. Protection of Cables and Hoses One of the primary benefits of CPS drag chains is their ability to shield cables and hoses from damage. By securely guiding these components through defined pathways, they prevent abrasion and excessive bending, which are common causes of cable failure.

2. Improved Mobility CPS drag chains facilitate seamless movement of machinery. They can adapt to various configurations, including linear and curved paths, allowing for maximum flexibility in equipment design. This adaptability ensures that cables are free from obstructions and can move alongside the machinery without hindrance.

3. Simplified Maintenance The organized structure of drag chains makes maintenance more straightforward. Technicians can quickly identify and access cables for inspections or replacements, reducing downtime and minimizing disruption to operations.

4. Enhanced Aesthetic Appeal Beyond their functional benefits, CPS drag chains also contribute to the aesthetic organization of machinery. A well-managed cable system presents a neat and professional appearance, which is particularly important in industries focused on quality and presentation.

5. Customizable Solutions CPS drag chains come in various shapes, sizes, and materials, making them highly customizable. Manufacturers can tailor the chains to suit specific machinery requirements, ensuring optimal compatibility and performance.

cps drag chain

Applications of CPS Drag Chains

CPS drag chains find applications across various industries, including

1. Manufacturing In automated production lines, CPS drag chains are crucial for guiding power cables and control cables, ensuring that machinery operates smoothly without interference.

2. Robotics Robotic arms and automated machines use drag chains to manage the plethora of cables required for power and signal transmission. This organization contributes to the efficiency and reliability of robotic operations.

3. CNC Machines Computer Numerical Control (CNC) machines benefit from CPS drag chains by reducing the risk of cable entanglement and protecting delicate wiring from mechanical damage, which is essential for maintaining precision.

4. Material Handling In logistics and warehouse automation, CPS drag chains are employed to keep cables organized on conveyor systems and automated guided vehicles (AGVs), enhancing operational efficiency.

5. Entertainment Industry The entertainment industry, particularly in staging and lighting, often uses CPS drag chains to manage the extensive cabling associated with lighting rigs, sound systems, and special effects equipment.

Conclusion

CPS drag chains are an integral component in the realm of industrial automation, providing essential cable management solutions that enhance machinery performance and durability. Their ability to protect cables from wear, improve mobility, streamline maintenance, and offer customizable designs makes them invaluable in various applications. As industries continue to evolve and embrace automation, the significance of CPS drag chains will only increase, solidifying their role as a key player in ensuring efficient and reliable operations. Understanding their function and advantages can help engineers and operators make informed decisions when optimizing their equipment and processes. Whether in manufacturing, robotics, or the entertainment sector, CPS drag chains pave the way for a more organized and efficient future in industrial operations.