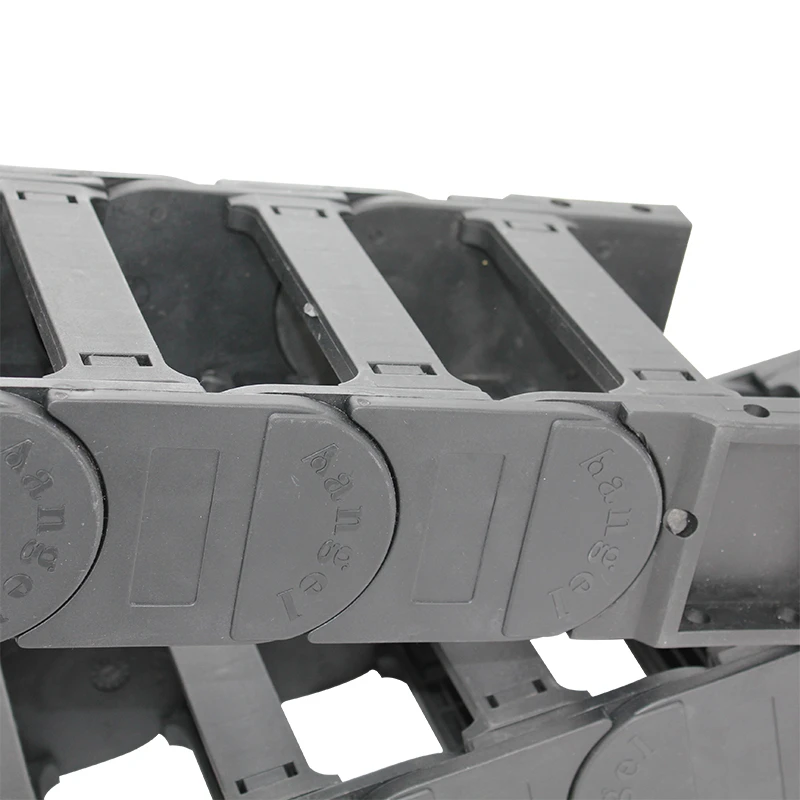

welded steel drag chain

The Advantages and Applications of Welded Steel Drag Chains

Welded steel drag chains are an essential component in various industrial applications, providing efficient and reliable solutions for the management and protection of electrical cables, hydraulic hoses, and other types of flexible lines. Their robust design and strength make them a favorable choice in environments where high durability and resistance to wear are crucial. This article explores the advantages and applications of welded steel drag chains in modern industries.

Strength and Durability

One of the primary benefits of welded steel drag chains is their exceptional strength. Made from high-quality steel, these chains can withstand significant stress and are inherently resistant to deformation under heavy loads. The welded construction method enhances the integrity of the chain, ensuring that it can handle dynamic movements and the rigors of industrial environments. Unlike plastic or lighter alternatives, welded steel drag chains do not succumb easily to wear and tear, making them a long-lasting option.

Protection of Cables and Hoses

In many industrial settings, cables and hoses are subject to harsh conditions, including exposure to chemicals, extreme temperatures, and physical abrasion. Welded steel drag chains provide a protective enclosure for these lines, preventing external damage and maintaining operational integrity. They effectively minimize the risk of accidental disconnections or wear, which can lead to costly downtime in production processes. By offering a safe path for cables and hoses, these chains improve overall safety and efficiency in the workplace.

Flexibility in Design

welded steel drag chain

Welded steel drag chains come in a variety of sizes and configurations, allowing for customization based on specific application requirements. Whether in narrow spaces or large industrial setups, these chains can be tailored to accommodate the needs of different machinery and equipment. The versatility extends to their ability to manage various types of loads, including those that twist, bend, or rotate. This flexibility enables industries to optimize their machinery layouts, facilitating smoother operations and enhancing productivity.

Applications Across Industries

The applications of welded steel drag chains are vast and varied. In the manufacturing sector, they are commonly found in CNC machines, assembly lines, and robotics, where the movement of cables and hoses is critical for operational success. They are also utilized in the automotive industry for automated assembly processes, ensuring that power and control lines are organized and secure.

Furthermore, in the construction and mining industries, welded steel drag chains safeguard vital connections in heavy equipment such as excavators and cranes. These chains are particularly valuable in harsh environments, where they enhance equipment reliability and longevity, significantly reducing maintenance costs.

Conclusion

In summary, welded steel drag chains are indispensable in modern industrial applications where strength, durability, and protection are paramount. Their ability to safeguard cables and hoses while offering flexibility in design makes them an ideal choice for a wide range of industries. As businesses strive for greater efficiency and reduced downtime, the adoption of robust solutions like welded steel drag chains will continue to play a crucial role in enhancing operational performance and safety. As technology evolves, these chains are likely to see further innovations, solidifying their status as a staple in industrial equipment management.