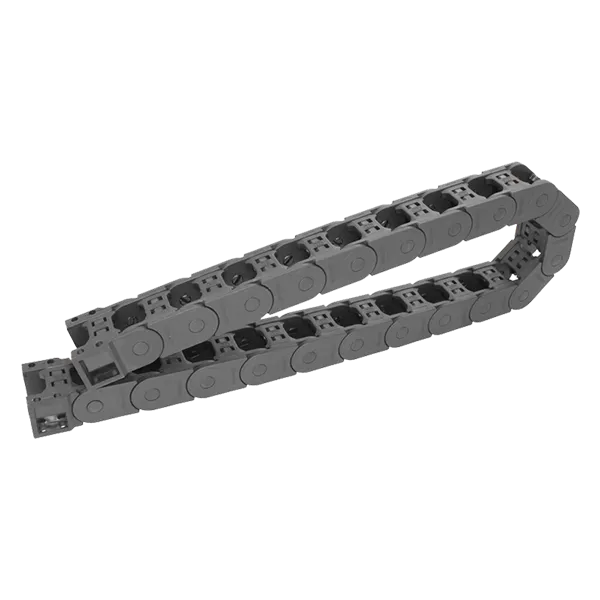

machine cable track

Understanding the Importance of Machine Cable Tracks

In an era characterized by rapid technological advancements, industrial machinery operates in increasingly complex environments. To optimize performance and safety, the design and integration of various components are paramount. One such critical component is the machine cable track. Although often overlooked, these tracks play a vital role in improving the efficiency and reliability of machinery across various industries.

What is a Machine Cable Track?

A machine cable track, also known as a cable carrier, is a protective system designed to guide and manage the movement of cables and hoses in machinery. These tracks ensure that cables remain organized, reducing wear and tear while minimizing the risk of accidental damage. They come in various forms, including modular designs that allow for customization based on specific needs.

Benefits of Using Cable Tracks

1. Protection Against Wear and Tear Cables are often subjected to continuous motion, bending, and movements that can lead to fraying or breaking. A cable track provides a dedicated path, preventing the cables from excessive bending and protecting them from harsh environments.

2. Enhanced Safety Loose cables can pose serious safety risks. They can lead to tripping hazards, potential electrical shorts, or even machinery malfunctions. By securing cables within a cable track, manufacturers can create a safer working environment for operators and reduce the risk of accidents.

3. Improved Organization In complex machinery, multiple cables and hoses can become tangled or disorganized over time. Cable tracks help maintain order, making it easier to identify and troubleshoot issues as they arise. This organization aids in maintenance efforts, contributing to overall operational efficiency.

4. Streamlined Maintenance When cables are properly managed in tracks, maintenance becomes a more straightforward task. Workers can access cables without the need to dismantle other machinery components. This not only saves time but also reduces labor costs and downtime.

machine cable track

5. Adaptability Modern cable tracks are designed to be flexible and adaptable to various applications. Whether in manufacturing, robotics, or automotive industries, cable tracks can be tailored to specific machinery requirements. They come in different materials, including plastic and metal, to suit diverse operating conditions.

6. Reduced Downtime The longer cables remain intact and undamaged, the less frequently they need to be replaced. By minimizing wear and tear through the use of cable tracks, businesses can reduce unplanned downtime associated with cable failures, enhancing productivity and profitability.

Considerations for Implementing Cable Tracks

When selecting and implementing cable tracks within machinery, several factors should be considered

- Cable Type Different cables require different levels of protection and flexibility. Assessing the type of cables being utilized will help in choosing the appropriate track system.

- Operating Environment Factors such as temperature, humidity, and exposure to chemicals should influence the material choice for the cable tracks.

- Movement Range and Speed Understanding the operational needs of the machinery, including the range of motion and speed at which cables will be moving, is vital for selecting the right cable track system.

Conclusion

Machine cable tracks may seem like a minor component in the intricate workings of industrial machinery, but their significance cannot be understated. By providing protection, organization, and safety for cables, these tracks enhance not only the longevity of the cables themselves but also the overall efficiency and safety of machinery operations. As industries continue to evolve, investing in cable management solutions like machine cable tracks will undoubtedly play a crucial role in optimizing performance and ensuring a safe working environment.