cable track system

The Importance of Cable Track Systems in Modern Industries

In today’s fast-paced industrial landscape, the efficiency and safety of machinery have become paramount. One of the critical components that contribute to these factors is the cable track system. These systems are engineered to manage and protect the various cables and hoses that power and control modern machines. The significance of cable track systems extends across various sectors, including manufacturing, robotics, automation, and telecommunications.

What is a Cable Track System?

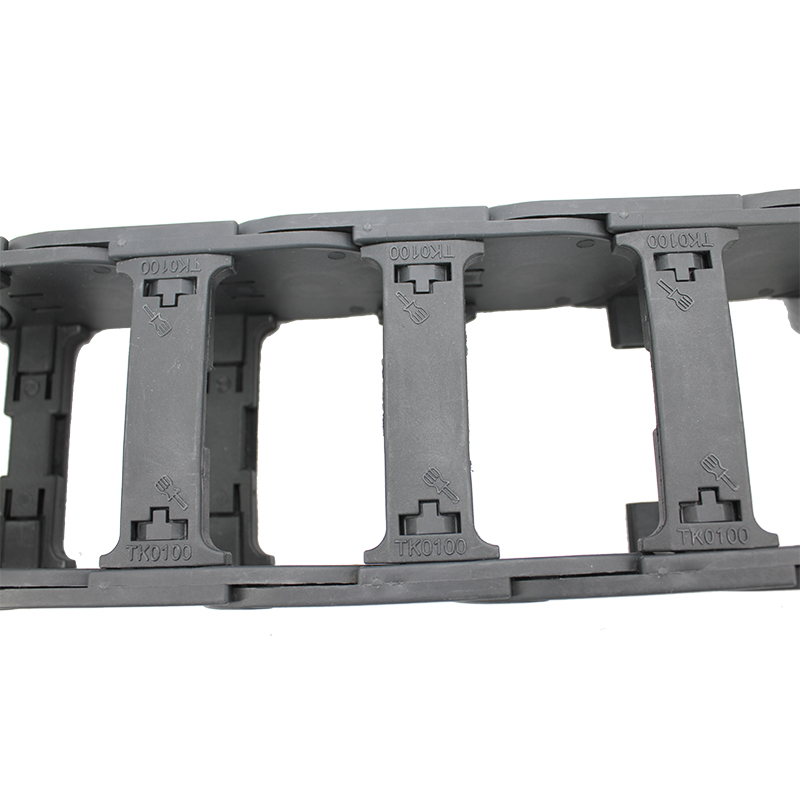

A cable track system, also known as drag chains or energy chains, consists of a series of interconnected links that form a flexible channel for guiding cables and hoses in a controlled manner. The primary purpose of these systems is to organize cables, preventing tangles and wear, which can lead to downtime and costly repairs. They are typically made from durable materials such as plastic or metal, providing both flexibility and stability.

Benefits of Cable Track Systems

1. Organization One of the primary benefits of cable track systems is their ability to keep cables organized. In environments where multiple machines operate in close proximity, tangled cables can pose significant safety hazards. A well-organized cable track system allows for easy identification and access, reducing the risk of accidents caused by tripping over loose cables.

2. Protection Cables and hoses are vulnerable to damage from environmental factors such as dust, oil, and extreme temperatures. Cable track systems shield these vital components from external hazards, thereby extending their lifespan. Additionally, these tracks protect cables from mechanical stress caused by movement, which can lead to wear and tear.

3. Flexibility and Mobility In industries where machinery needs to move freely, cable track systems provide the flexibility required. They can fit various applications, from robotic arms in an assembly line to stationary machinery in manufacturing plants. The design of these systems allows them to accommodate bending and twisting motions, ensuring that cables remain intact and functional.

cable track system

4. Efficiency By minimizing cable wear and ensuring that they stay organized, cable track systems contribute to the overall operational efficiency of industrial settings. Less downtime due to maintenance and repairs translates to higher productivity, ultimately affecting a company's bottom line positively.

Applications of Cable Track Systems

Cable track systems find applications in an array of industries. In manufacturing plants, they are used to guide cables in automated machinery, ensuring seamless operation. In robotics, these systems are essential for supplying power and data to moving parts, allowing robots to perform their tasks without interruption. Moreover, in the telecommunications industry, cable track systems help maintain the integrity of critical communication lines.

Choosing the Right Cable Track System

When selecting a cable track system, several factors should be considered, including the type of cables, the environment in which the system will operate, and the degree of movement required. It's crucial to choose a system that can adequately protect and organize the specific cables used in an application.

Conclusion

In conclusion, cable track systems play a vital role in enhancing safety, organization, and efficiency within various industrial applications. As technology advances and industries evolve, the demand for reliable cable management solutions will continue to grow. Investing in quality cable track systems is not just an operational choice; it's a strategic decision for any organization looking to improve its productivity and ensure a safe working environment.