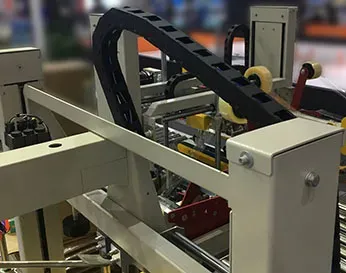

welded steel drag chain

Welded Steel Drag Chains A Comprehensive Overview

Welded steel drag chains play a crucial role in various industrial applications, providing efficient transportation and protection for cables and hoses in moving machinery. These chains are designed to endure harsh environments while maintaining a high level of performance and durability. This article explores the features, advantages, applications, and maintenance of welded steel drag chains.

What are Welded Steel Drag Chains?

Welded steel drag chains, also known as cable carriers or energy chains, are specifically engineered guides that facilitate the movement of cables and hoses. Constructed from high-quality welded steel, these chains are built to withstand heavy loads and dynamic movement. The welded design enhances strength and durability, making them ideal for environments where plastic or lighter materials would fail.

Key Features

1. Robust Construction The primary feature of welded steel drag chains is their robust construction. The steel is often treated with corrosion-resistant coatings, ensuring longevity even in challenging conditions.

2. Modular Design These chains come in modular components that can be easily assembled and disassembled. This flexibility enables customization to fit various machinery layouts and specific operational needs.

3. High Load Capacity Welded steel drag chains are designed to handle significant weights. This makes them suitable for heavy machinery and equipment found in manufacturing plants, construction sites, and other industrial sectors.

4. Smooth Movement The design of welded steel drag chains facilitates smooth movement of cables and hoses. This feature minimizes wear and tear on the components, extending their lifespan and reducing maintenance costs.

5. Versatility The adaptability of these chains allows them to be used in a multitude of settings, from automated production lines to robotic applications. They can accommodate different types of cables and hoses, providing a universal solution for various industries.

Advantages of Using Welded Steel Drag Chains

1. Durability The steel construction provides superior resistance to wear, impact, and environmental factors such as temperature fluctuations, dust, and chemicals.

2. Safety By securely enclosing cables and hoses, these chains minimize the risk of entanglement and damage. This contributes to a safer working environment and reduces downtime caused by cable failures.

welded steel drag chain

3. Reduced Maintenance The robust nature of welded steel drag chains necessitates less frequent repairs and replacements, resulting in lower operational costs over time.

4. Improved Efficiency The smooth operation of the chains enhances the overall efficiency of machinery. Equipment can function more reliably without the risk of cable snagging or wear.

Applications

Welded steel drag chains are used in a variety of applications across multiple industries, including

- Automotive Manufacturing In automated assembly lines where precision and timing are critical. - Construction Equipment Where heavy-duty performance is a necessity, such as on cranes and excavators. - Robotics In robotic arms and automated machinery, where freedom of movement for cables and hoses is essential. - CNC Machining Where tools and equipment require dynamic movement and protection of vital connections.

Maintenance Tips

To ensure the longevity and optimal performance of welded steel drag chains, regular maintenance is required. Here are some tips to follow

1. Routine Inspections Regularly check for signs of wear and tear, such as cracks or deformations. Early detection can prevent more extensive damage.

2. Lubrication Keep the chains lubricated to minimize friction and wear. Refer to manufacturer guidelines for the appropriate lubrication methods and products.

3. Cleaning Periodically clean the chains to remove dust, debris, and other contaminants that could affect performance.

4. Proper Installation Ensure that the chains are installed correctly to avoid unnecessary strain and damage. Follow the manufacturer’s installation guidelines closely.

Conclusion

Welded steel drag chains are an essential component in the realm of industrial machinery, offering a unique combination of durability, load capacity, and flexibility. Their ability to securely manage cables and hoses under demanding conditions makes them an invaluable choice for industries ranging from automotive to robotics. By understanding their features, applications, and maintenance needs, businesses can leverage the benefits of welded steel drag chains to enhance operational efficiency and safety.