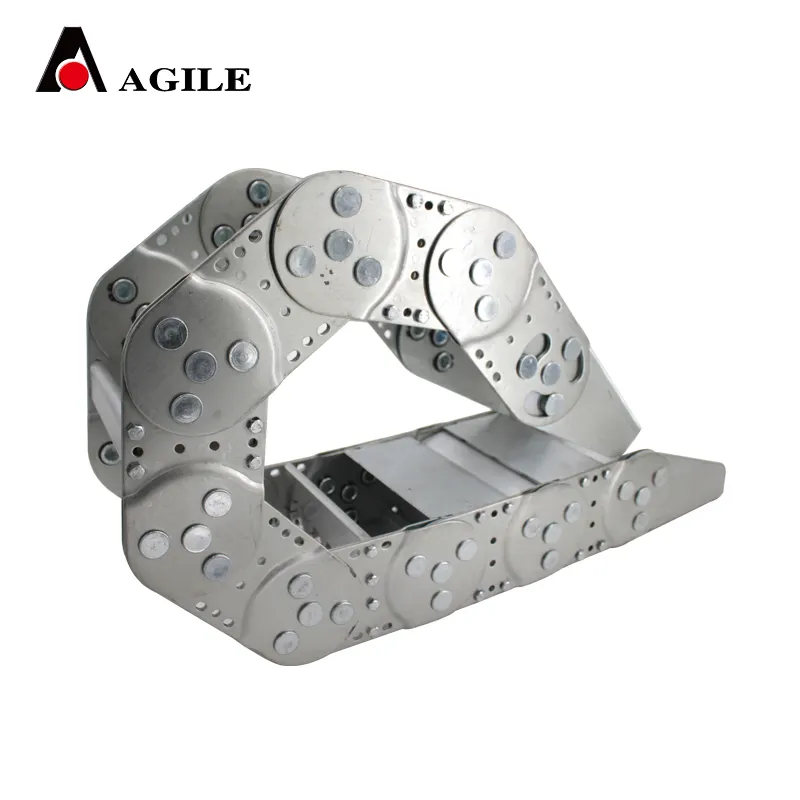

cable carrier system

The Cable Carrier System An Essential Solution for Efficient Cable Management

In today’s fast-paced industrial environment, efficient cable management has become a critical factor in ensuring the longevity and safety of machinery. The Cable Carrier System, also known as Energy Chains or Drag Chains, provides a robust solution for managing cables and hoses in various applications. This article explores the functionality, benefits, applications, and future prospects of cable carrier systems, highlighting their importance in modern engineering.

What is a Cable Carrier System?

A cable carrier system consists of a series of interlocking links that form a flexible chain-like structure. This system is designed to guide and protect moving cables and hoses, allowing them to move smoothly alongside machinery without tangling or sustaining damage. Typically made of durable materials such as plastic or metal, cable carriers come in various shapes, sizes, and designs to accommodate different environments and operational needs.

Functionality and Design

The primary function of a cable carrier system is to provide structured pathways for cables and hoses while allowing for unrestricted movement. As machinery operates, especially in dynamic environments like manufacturing plants, cables can frequently tangle, wear out, or become damaged. Cable carriers prevent these issues by keeping cables organized and within designated paths.

The design of a cable carrier system varies based on the specific application. For example, some designs focus on high-speed machinery, while others cater to applications requiring more flexibility. Innovations in materials and technology have led to lighter, more resilient carriers that can operate in extreme conditions, from high heat to corrosive environments.

Advantages of Cable Carrier Systems

1. Protection of Cables and Hoses One of the primary advantages of cable carrier systems is their ability to protect sensitive cables and hoses from wear and abrasion. This protection ensures a longer lifespan and reduces the need for frequent replacements.

2. Enhanced Mobility Cable carriers enable smooth and efficient movement of cables and hoses, especially in setups involving robotic arms, conveyor belts, and other dynamic machinery. This mobility allows for seamless operations in a variety of industrial processes.

3. Safety By containing and organizing cables, cable carrier systems help to reduce the risk of accidents caused by tripping hazards. A tidy workspace promotes a safer environment, minimizing potential liabilities for businesses.

cable carrier system

4. Reduced Downtime With their ability to protect cables and ensure efficient movement, cable carrier systems significantly minimize downtime caused by maintenance or repairs. This reliability translates to greater productivity and better overall performance.

5. Customizability Cable carriers come in a variety of configurations, allowing companies to select systems that best suit their specific needs. Whether it’s in terms of size, materials, or additional features, the versatility of cable carriers makes them an ideal choice for diverse applications.

Applications of Cable Carrier Systems

Cable carrier systems are used in a broad range of industries, including manufacturing, robotics, automotive, and aerospace. In manufacturing environments, they are often seen in conveyor systems, CNC machines, and automated assembly lines. In the robotics sector, cable carriers ensure that wiring and hoses remain organized and functional, even during fast movements and rotations. The aerospace industry utilizes cable carriers for aircraft systems, where reliability and safety are paramount.

Additionally, cable carrier systems are prevalent in the entertainment industry, where they manage lighting and sound cables in concerts and theater productions. Their adaptability to various environments further cements their status as a fundamental component in contemporary engineering.

The Future of Cable Carrier Systems

As industries evolve, so too will the demands placed on cable management solutions. The future of cable carrier systems lies in advancements in materials and technology. Innovations such as smart cable carriers equipped with sensors for monitoring wear and tear may soon become commonplace, ensuring that maintenance is proactive rather than reactive.

Moreover, as automation and robotics continue to advance, the demand for efficient cable management solutions will only increase. Companies that invest in modern cable carrier systems will likely gain a competitive edge by improving operational efficiency and reducing costs.

Conclusion

In summary, the Cable Carrier System plays a vital role in ensuring efficient cable management across various industries. Its robust design, combined with numerous advantages, makes it an indispensable asset in modern machinery. As technology progresses, the evolution of cable carrier systems will continue to enhance their functionality, providing businesses with innovative solutions to meet the demands of a dynamic industrial landscape. For any organization that values efficiency, safety, and reliability, investing in a quality cable carrier system is a decision that will yield significant returns.