Wood Chip Screw Conveyor - Efficient Material Handling Solutions

Wood Chip Screw Conveyor An Efficient Solution for Material Handling

In the realm of material handling, especially in industries dealing with wood and biomass, the efficient transport of wood chips is crucial. One standout solution that has gained popularity is the wood chip screw conveyor. This equipment not only offers effective transport but also ensures the preservation of material integrity during the movement process.

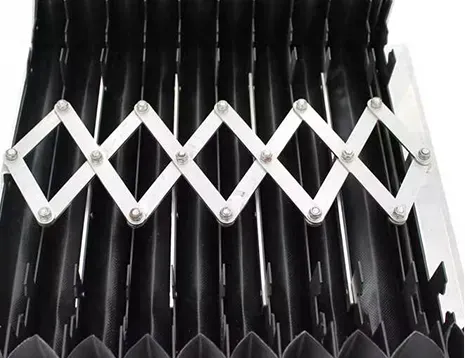

A wood chip screw conveyor operates on a simple yet effective principle a rotating helical screw, also known as an auger, moves wood chips from one location to another. This design allows for continuous and consistent flow, making it an ideal choice for facilities that require high throughput. Unlike traditional belt conveyors, screw conveyors can handle varying material consistencies and sizes, making them versatile for different wood chip forms, whether they are small shavings or larger chunks.

One of the primary advantages of using screw conveyors for wood chips is their ability to minimize material degradation. The enclosed design of the conveyor system reduces the risk of wear and tear on the chips caused by external factors like contaminants or excess moisture. Moreover, due to the gentle handling mechanism, the conveyor helps maintain the quality of the wood chips, which is essential for subsequent processing stages, such as pelletizing or combustion.

wood chip screw conveyor

The installation of a wood chip screw conveyor can significantly enhance operational efficiency. With the ability to be designed for horizontal, inclined, or vertical transport, these conveyors provide flexibility in layout. This adaptability allows industries to save valuable space while maximizing transport capability. Furthermore, screw conveyors can be customized in terms of size, pitch, and material, ensuring compatibility with specific requirements and conditions.

Energy efficiency is another notable benefit of screw conveyors. They typically consume less energy compared to other material handling systems, further driving down operational costs. Additionally, most modern designs incorporate features that reduce noise and minimize wear, contributing to a more sustainable operational environment.

Maintenance of a wood chip screw conveyor is relatively straightforward. Regular inspections and routine maintenance help ensure optimal performance and longevity. Yet, such systems are engineered for durability, often requiring less frequent repairs than alternative conveyor systems.

In conclusion, the wood chip screw conveyor emerges as a highly efficient solution for transporting wood chips in various industrial applications. With benefits such as reduced material degradation, flexibility in design, energy efficiency, and ease of maintenance, it's clear that utilizing this technology can greatly enhance productivity in wood processing facilities. As industries seek to optimize their operations, wood chip screw conveyors stand out as a reliable and effective choice for material handling needs.