Innovative Spiral Chip Conveyor for Enhanced Material Handling Efficiency

The Spiral Chip Conveyor An Innovative Solution for Efficient Material Handling

In the realm of manufacturing and processing industries, efficient material handling is crucial for optimizing productivity and minimizing waste. Among the advanced solutions available, the spiral chip conveyor stands out as a highly effective system designed to manage the transport of metal chips and other bulk materials. This innovative technology not only streamlines manufacturing processes but also enhances overall operational efficiency.

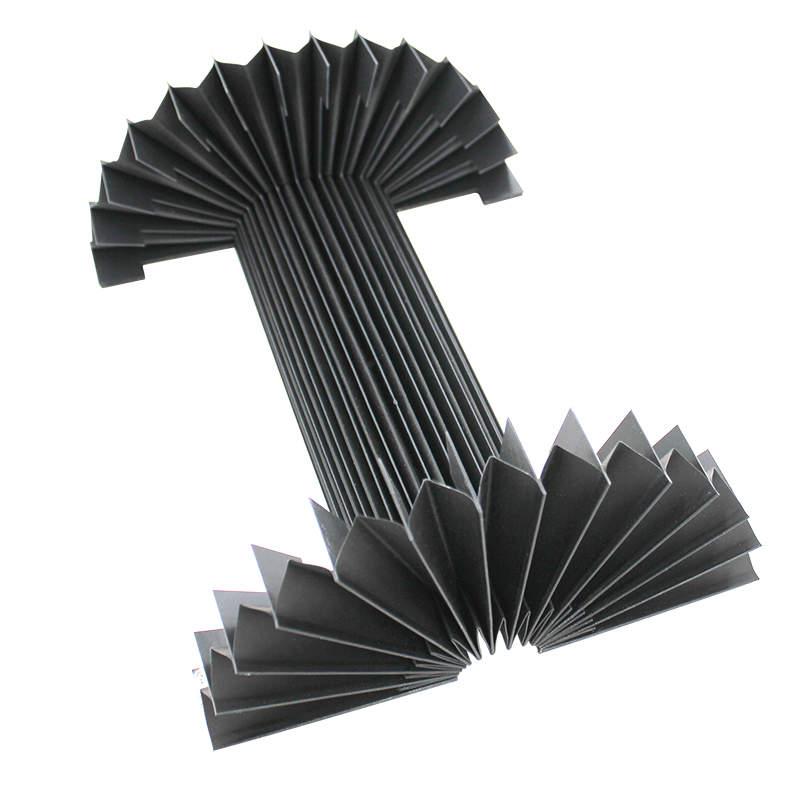

The spiral chip conveyor is engineered to move materials in a vertical or inclined manner, utilizing a helical screw mechanism housed within a robust casing. This design allows for space-saving configurations, making it ideal for environments where floor space is at a premium. Unlike traditional conveyors that typically operate on a linear path, the spiral design efficiently elevates materials, maximizing the use of available vertical space.

One significant advantage of the spiral chip conveyor is its ability to handle a variety of materials

. In industries such as metalworking, where metal shavings and chips are generated during machining processes, the spiral conveyor effectively collects and transports these by-products to designated disposal areas or recycling stations. This not only helps keep the work environment clean and safe but also contributes to sustainability efforts by ensuring that valuable materials are recycled rather than discarded.spiral chip conveyor

Moreover, the spiral chip conveyor is designed for durability and reliability. Constructed from high-quality materials resistant to wear and corrosion, these conveyors can withstand the harsh conditions often found in manufacturing environments. Maintenance is typically straightforward, with easy access to components, minimizing downtime and ensuring smooth operation.

Another aspect worth noting is the adaptability of spiral chip conveyors to various production lines. They can be integrated into existing systems with relative ease, allowing manufacturers to upgrade their material handling processes without extensive modifications. Additionally, their modular design enables customization to fit specific operational needs, ensuring optimal performance tailored to individual applications.

In conclusion, the spiral chip conveyor represents a significant advancement in material handling technology. By offering efficient, safe, and sustainable solutions for transporting metal chips and other bulk materials, it greatly enhances operational workflows in the manufacturing sector. As industries continue to seek innovative ways to improve efficiency and reduce waste, the adoption of spiral chip conveyors is likely to become increasingly widespread, paving the way for a more streamlined and environmentally friendly future in production practices.