Innovative Spiral Chip Conveyor Design for Efficient Material Handling Solutions

The Spiral Chip Conveyor Revolutionizing Material Handling

In the world of manufacturing and material handling, efficiency and ingenuity stand as cornerstones of productivity. Among the myriad of solutions developed to optimize the movement and management of materials, the spiral chip conveyor has emerged as a game-changer. This innovative system addresses some of the most persistent challenges in the industry, particularly those related to the transport of chips, shavings, and other small machined materials.

Understanding the Spiral Chip Conveyor

The spiral chip conveyor is a specialized material handling device designed to move chips and particles vertically or at an angle, as opposed to traditional conveyors that often work horizontally or in a straight line. Its unique helical design allows for a compact footprint, making it suitable for installations with limited space. Typically made of durable materials such as steel, this conveyor system features a continuous spiral element that moves materials through a casing, using gravity and rotational motion.

Advantages of Spiral Chip Conveyors

1. Space Efficiency The spiral design allows these conveyors to operate in tight spaces, making them ideal for shops and factories where floor space is at a premium. Unlike standard conveyors that require extensive horizontal space, spiral chip conveyors can run vertically, achieving significant elevation without taking up much room.

2. Versatility Spiral chip conveyors are incredibly versatile. They can handle various types of materials—metal chips, plastic shavings, and other small particles—making them suitable for multiple industries, including metalworking, woodworking, and recycling. This adaptability ensures that businesses can maintain a single solution for diverse material types.

3. Reduced Operational Footprint Since they can transport materials vertically, spiral conveyors minimize the need for additional equipment and systems. This reduction in equipment not only saves on capital expenditures but also leads to lower maintenance costs and streamlined operational processes.

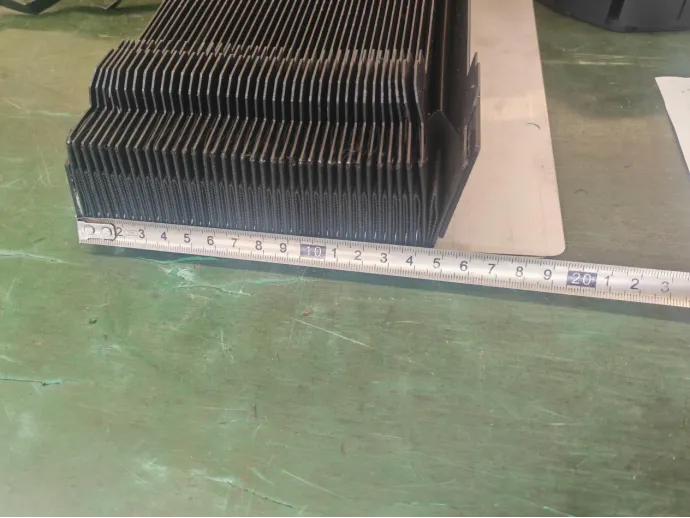

spiral chip conveyor

4. Improved Safety By enclosing materials within a casing, spiral chip conveyors enhance safety in the workplace. Loose chips and debris are contained, significantly reducing the risk of slips, trips, and falls. Furthermore, the ergonomic design aids in reducing worker fatigue, as operators do not have to bend or reach awkwardly to manage materials.

5. Increased Efficiency The smooth operation of the spiral chip conveyor results in increased throughput. Companies can transport materials from machines directly to disposal or recycling areas efficiently, minimizing downtime and boosting productivity.

Applications Across Industries

Spiral chip conveyors are commonly used in various sectors. In metalworking, for instance, they efficiently collect and transport swarf (metal chips and shavings) generated during machining processes. This is crucial for maintaining a clean and safe work environment. In recycling operations, spiral conveyors help in sorting different materials, facilitating the efficient processing of waste and promoting sustainability.

Woodworking facilities also benefit from these conveyors as they can manage sawdust and wood chips, thereby aiding in the reduction of waste and improving overall resource management.

Conclusion

The rise of the spiral chip conveyor marks a significant advancement in the field of material handling. By addressing issues of space, versatility, safety, and operational efficiency, these innovative conveyors provide a robust solution for industries grappling with the challenges of material transport. As manufacturers continue to seek ways to optimize production processes and increase workplace safety, the spiral chip conveyor stands out as an essential tool in the arsenal of modern manufacturing technologies. Embracing this technology not only enhances productivity but also signals a commitment to innovation and improvement in the ever-evolving landscape of industry.