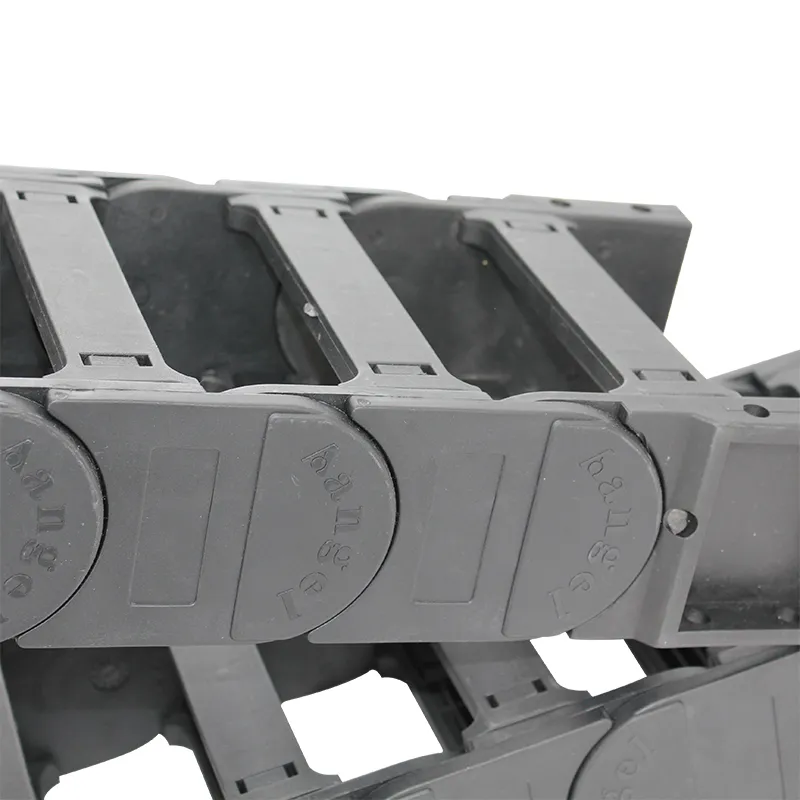

metal chip conveyor

In the world of modern manufacturing, maintaining cleanliness and efficiency on the shop floor is paramount to productivity and quality outcomes. A key component in achieving this is the effective disposal of metal shavings and chips that result from machining operations. Scraper chip conveyors are the unsung heroes of this task, offering a reliable and efficient means of handling these byproducts. This article delves into the intricacies of scraper chip conveyors, highlighting their benefits, functionality, and the factors that underscore their choice in an industrial setting.

Technologically, scraper chip conveyors have evolved significantly with the introduction of intelligent systems. Modern iterations are equipped with sensors and IoT capabilities, allowing operators to monitor performance in real-time. Such integrations can provide vital insights into conveyor speed, chip volume, and maintenance needs, paving the way for predictive maintenance regimes. This proactive approach not only extends the operational life of the machinery but also ensures that plant downtime is minimized—critical in high-stakes manufacturing environments where every second of operational time counts. When selecting scraper chip conveyors, several factors need to be considered to ensure the chosen solution aligns with the specific needs of a given application. Key considerations include the volume and type of chips produced, the space available for the conveyor system, integration capabilities with existing machinery, and the ease of maintenance. Understanding these aspects requires expertise not just in conveyors, but also in the broader context of the production process, which underscores the importance of engaging with supplier partners who bring both knowledge and a track record of reliability. The authoritativeness of a supplier can be gauged by their industry expertise and the extent of customization they offer. Renowned manufacturers provide support in designing systems that are bespoke to an operation’s requirements, ensuring that the solution not only fits seamlessly into the workflow but also anticipates future scaling needs. Comprehensive warranties, after-sales support, and a robust portfolio of past installations further establish trustworthiness—a critical metric in long-term capital equipment investments. In conclusion, scraper chip conveyors provide an essential function on the manufacturing floor by efficiently managing metal waste, thus enhancing both productivity and safety. Their adaptability to various machining environments, coupled with technological advancements, make them a preferred choice in diverse industrial settings. By selecting the right partner rooted in expertise and credibility, businesses can harness these systems to sustain competitive industrial operations.

Technologically, scraper chip conveyors have evolved significantly with the introduction of intelligent systems. Modern iterations are equipped with sensors and IoT capabilities, allowing operators to monitor performance in real-time. Such integrations can provide vital insights into conveyor speed, chip volume, and maintenance needs, paving the way for predictive maintenance regimes. This proactive approach not only extends the operational life of the machinery but also ensures that plant downtime is minimized—critical in high-stakes manufacturing environments where every second of operational time counts. When selecting scraper chip conveyors, several factors need to be considered to ensure the chosen solution aligns with the specific needs of a given application. Key considerations include the volume and type of chips produced, the space available for the conveyor system, integration capabilities with existing machinery, and the ease of maintenance. Understanding these aspects requires expertise not just in conveyors, but also in the broader context of the production process, which underscores the importance of engaging with supplier partners who bring both knowledge and a track record of reliability. The authoritativeness of a supplier can be gauged by their industry expertise and the extent of customization they offer. Renowned manufacturers provide support in designing systems that are bespoke to an operation’s requirements, ensuring that the solution not only fits seamlessly into the workflow but also anticipates future scaling needs. Comprehensive warranties, after-sales support, and a robust portfolio of past installations further establish trustworthiness—a critical metric in long-term capital equipment investments. In conclusion, scraper chip conveyors provide an essential function on the manufacturing floor by efficiently managing metal waste, thus enhancing both productivity and safety. Their adaptability to various machining environments, coupled with technological advancements, make them a preferred choice in diverse industrial settings. By selecting the right partner rooted in expertise and credibility, businesses can harness these systems to sustain competitive industrial operations.