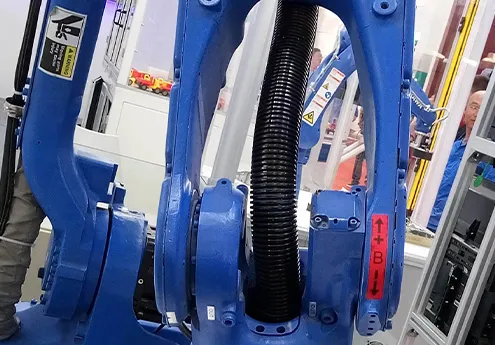

plastic cable chain track

The Versatility and Advantages of Plastic Cable Chain Tracks

In an age of rapid technological advancement and automation, efficient management of cables and hoses has become a critical concern for industries around the world. One of the most effective solutions to this challenge is the use of plastic cable chain tracks. These innovative components provide exceptional support and organization for cables, hoses, and pipes, contributing to the seamless functioning of machinery and equipment across various applications. This article delves into the features, benefits, and applications of plastic cable chain tracks.

What is a Plastic Cable Chain Track?

Plastic cable chain tracks, often referred to as cable carriers or drag chains, are designed to house and protect movable cables and hoses in machinery while allowing them to flex and move freely. Typically manufactured from high-quality plastic materials such as PA (Polyamide) and POM (Polyoxymethylene), these tracks are lightweight, durable, and resistant to wear and tear. Their modular design allows easy assembly and customization to suit specific operational requirements.

Key Features

1. Flexibility and Mobility Plastic cable chain tracks are designed to accommodate a wide range of movements, including linear and rotational motion. This flexibility is essential in applications such as robotic arms, CNC machines, and automated conveyor systems, where cables must move without becoming entangled or stressed.

2. Durability and Resistance Made from robust plastic materials, these tracks provide excellent resistance to chemicals, oils, and temperature fluctuations. This durability ensures that the cables and hoses they protect remain safe in harsh environments, reducing the risk of wear, damage, and downtime.

3. Lightweight Design One of the biggest advantages of plastic cable chain tracks is their lightweight nature. This reduces the overall weight of machinery, allowing better energy efficiency and easier integration into various systems.

4. Modular Construction The modular design of plastic cable chains allows for customization and easy assembly. Users can connect multiple segments to achieve the required length and shape, making them suitable for diverse applications.

5. Noise Reduction The use of high-quality plastic materials helps to minimize noise during operation. This is particularly beneficial in environments where excessive noise can be a distraction or safety concern.

plastic cable chain track

Benefits of Using Plastic Cable Chain Tracks

1. Enhanced Organization By providing a dedicated pathway for cables and hoses, plastic cable chain tracks help prevent tangling and reduce the risk of damage. This promotes a cleaner and more organized workspace.

2. Increased Lifespan of Cables Protecting cables from abrasion and damage can significantly extend their lifespan. This not only saves on replacement costs but also minimizes downtime due to maintenance.

3. Improved Safety Having cables and hoses organized within a cable chain reduces the risk of accidents and injuries. It helps provide a safer work environment by eliminating tripping hazards associated with loose cables.

4. Cost-Effectiveness While the initial investment in plastic cable chain tracks may seem significant, the long-term benefits—such as decreased maintenance costs, reduced downtime, and extended cable life—make them a cost-effective solution.

Applications of Plastic Cable Chain Tracks

Plastic cable chain tracks find widespread use across numerous industries, including

- Manufacturing In automated production lines, cable chains help manage the multitude of cables needed for machinery operation. - Robotics Robotic applications demand high mobility and flexibility, making plastic cable chains an ideal choice for managing control cables. - Elevators and Lift Systems Cable carriers assist in organizing control and power cables within lift systems to ensure safety and functionality. - Automotive In automotive assembly lines, these cable tracks are essential for managing wiring in robotic arms that assemble vehicles.

Conclusion

Plastic cable chain tracks are a vital component in the modern industrial landscape. Their flexibility, durability, and organizational capabilities make them indispensable for maintaining the efficiency and safety of machinery. As industries continue to automate and evolve, the reliance on innovative solutions like plastic cable chain tracks will undoubtedly strengthen, paving the way for even greater advancements in technology and productivity.