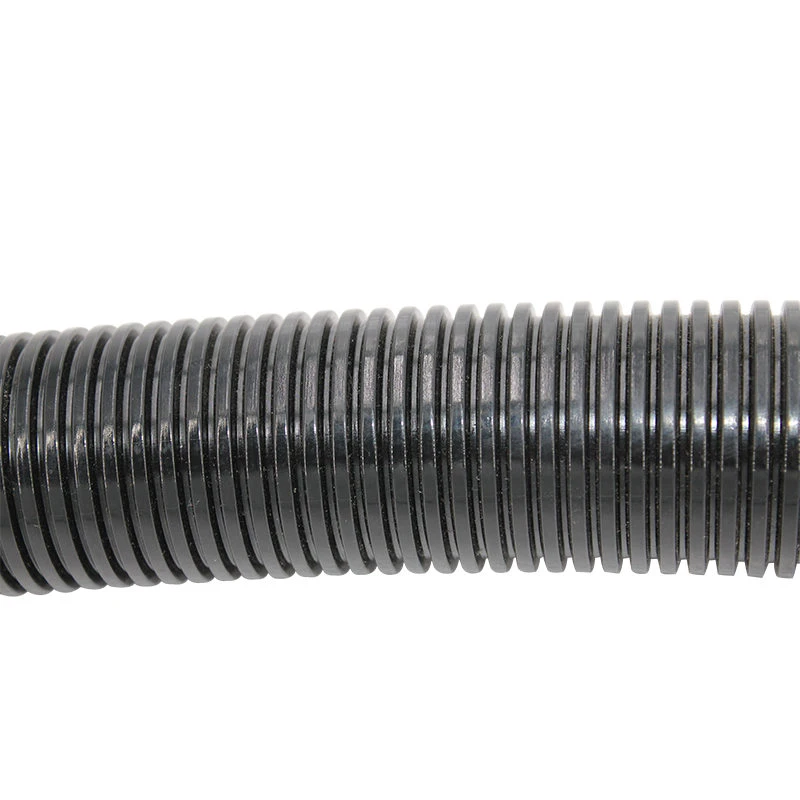

non split loom

The Non-Split Loom Innovation in Weaving Technology

In the world of textiles, innovation has always played a crucial role in enhancing productivity and improving the quality of fabrics. One of the more recent advancements that has gained attention in the industry is the non-split loom. Unlike traditional looms that either split or can be modified to do so, non-split looms present a unique solution that fosters efficiency and versatility in textile manufacturing.

Understanding Non-Split Loom Technology

A non-split loom operates on a design principle that eliminates the need for splitting the warp threads during production. This technology is particularly appreciated in the manufacture of intricate, high-quality fabrics where consistency and tension are paramount. In traditional looms, the splitting of warp threads could lead to discrepancies in thread tension and weave density. However, with non-split looms, this risk is significantly reduced, leading to more uniform fabric production.

The mechanics of a non-split loom involve harnesses that control the lifting of warp threads without the need for splitting. This streamlined process not only simplifies weaving but also allows for greater customization and adaptability of the woven fabric. By maintaining consistent tension and alignment of the yarns, manufacturers can produce textiles that are both durable and aesthetically appealing.

Benefits of Non-Split Looms

1. Enhanced Fabric Quality The ability to maintain consistent thread tension throughout the weaving process results in superior fabric quality. Fabrics produced on non-split looms exhibit fewer defects, reduced fraying, and a more uniform appearance, making them more appealing to consumers.

2. Increased Production Speed Non-split looms offer quicker setup times compared to traditional looms. The simplified threading process and reduced need for adjustments allow manufacturers to increase their production rates, thereby meeting market demands more efficiently.

3. Versatility Manufacturers can easily switch between different fabric types and patterns on a non-split loom without extensive reconfiguration. This versatility enables businesses to respond swiftly to changes in consumer preferences, producing a wider variety of textiles while maintaining high quality.

non split loom

4. Reduced Waste With improved accuracy in the weaving process, non-split looms contribute to the reduction of material waste. The more efficient use of yarns not only benefits manufacturers economically but also aligns with sustainability goals in the textile industry.

Case Studies

Numerous textile manufacturers have adopted non-split loom technology and have reported remarkable results. For instance, a prominent fabric company that transitioned to non-split looms found a 30% increase in productivity alongside a significant improvement in customer satisfaction due to the enhanced quality of their products. Similarly, smaller firms leveraging this technology have been able to compete effectively in niche markets, offering bespoke textiles that are both durable and visually appealing.

Future of Non-Split Looms

As the demand for high-quality textiles continues to grow, non-split looms are poised to play an integral role in the evolution of the textile industry. The ongoing advancements in technology, including automation and digital weaving processes, are likely to further enhance the capabilities of non-split looms. Manufacturers are already experimenting with smart looms that enable real-time monitoring and adjustments, ensuring even greater precision and efficiency.

Moreover, as sustainability becomes a significant focus for consumers, the efficiency and reduced waste associated with non-split looms may provide companies with a competitive edge. By producing high-quality fabrics in a more sustainable manner, businesses can not only meet consumer demands but also contribute positively to the environment.

Conclusion

The non-split loom represents a significant leap forward in weaving technology. By combining efficiency, quality, and adaptability, these looms are redefining textile production. As the industry continues to evolve, the non-split loom will undoubtedly play a pivotal role in shaping the future of textiles, making it an important topic for manufacturers, designers, and sustainability advocates alike.