Compact Cable Carrier for Efficient Wire Management Solutions

Understanding Mini Drag Chains A Comprehensive Overview

Mini drag chains are an essential component in modern engineering, particularly in applications requiring efficient cable management. Known for their compact design and versatility, these drag chains are widely used in various industries, including manufacturing, robotics, and automation. This article delves into the features, benefits, and applications of mini drag chains, highlighting their significance in today’s technological landscape.

What is a Mini Drag Chain?

A mini drag chain, also known as a cable carrier or energy chain, is a flexible conduit used to route and protect cables and hoses in moving machinery. Unlike traditional cable management systems, mini drag chains are designed for confined spaces, ensuring cables remain organized and free from tangles and abrasion during operation. Typically made from materials such as nylon or polyurethane, these chains provide durability and longevity under demanding conditions.

Key Features

1. Compact Design One of the standout features of mini drag chains is their small size. This design allows them to fit into tight spaces where larger carriers would be impractical. This makes them ideal for applications such as CNC machines and robotic arms.

2. Flexibility and Mobility Mini drag chains are designed to facilitate smooth movement. They can bend, twist, and flex without compromising the integrity of the cables they house. This flexibility is crucial for dynamic applications where machinery components move in multiple directions.

3. Customizable Links Many mini drag chains come with customizable link sizes, which allow users to adjust the chain’s dimensions to accommodate various cable sizes and types. This feature enhances the drag chain’s adaptability across different machines and applications.

4. Ease of Installation The design of mini drag chains simplifies installation. Most chains can be mounted easily on equipment frames, and their modular design often allows for quick assembly and disassembly, further streamlining maintenance processes.

5. Protection from Environmental Factors Mini drag chains provide effective protection against dust, debris, and other environmental factors that could damage cables and hoses. This protective quality significantly enhances the lifespan of the components they carry.

Benefits of Using Mini Drag Chains

The incorporation of mini drag chains into machinery brings numerous benefits

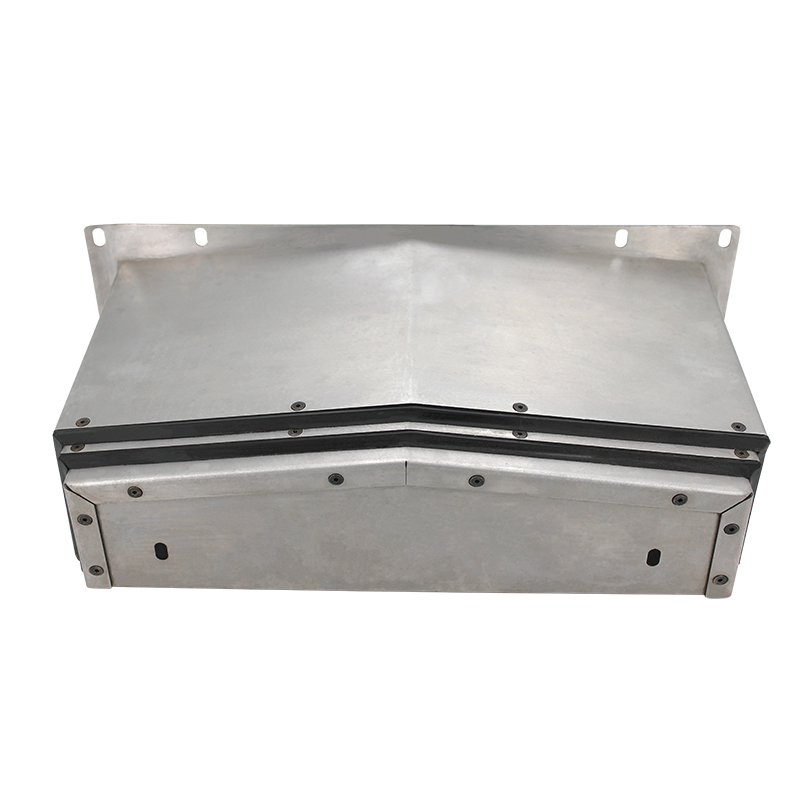

mini drag chain

- Enhanced Cable Life By preventing cables from snagging, twisting, or tangling, mini drag chains significantly prolong the life of cables and hoses, reducing the need for frequent replacements and thereby saving costs.

- Improved Safety With organized cables, there is a decreased risk of tripping hazards in workplaces. Minimizing cable wear also reduces the risk of electrical failures, enhancing overall workplace safety.

- Increased Efficiency These drag chains optimize the routing of cables and hoses, preventing interference with machinery operations. This streamlining can lead to improved operational efficiency and productivity.

- Cost-Effectiveness The initial investment in mini drag chains can yield significant savings over time due to reduced downtime, lower maintenance costs, and the enhanced durability of the equipment.

Applications of Mini Drag Chains

Mini drag chains find applications across various industries, including

- Robotics In robotic systems, mini drag chains facilitate the movement of electrical cables, allowing robots to operate seamlessly across workspaces.

- Automation Systems These chains are crucial in automated production environments, where multiple components move simultaneously. They help organize and protect the numerous cables required for sensors, motors, and controllers.

- CNC Machinery In CNC applications, where precision and movement are paramount, mini drag chains ensure that cables are adequately managed, contributing to smooth operational performance.

- Medical Equipment Many medical devices incorporate mini drag chains to maintain the integrity of cables in environments that require a high standard of hygiene and repairability.

Conclusion

Mini drag chains are an innovative solution to the challenges of cable management in dynamic environments. Their compact design, flexibility, and protective qualities make them indispensable in various applications, from manufacturing to robotics. As technology continues to advance, the importance of efficient and reliable cable management solutions, such as mini drag chains, will undoubtedly grow, further solidifying their role in modern engineering and production processes.