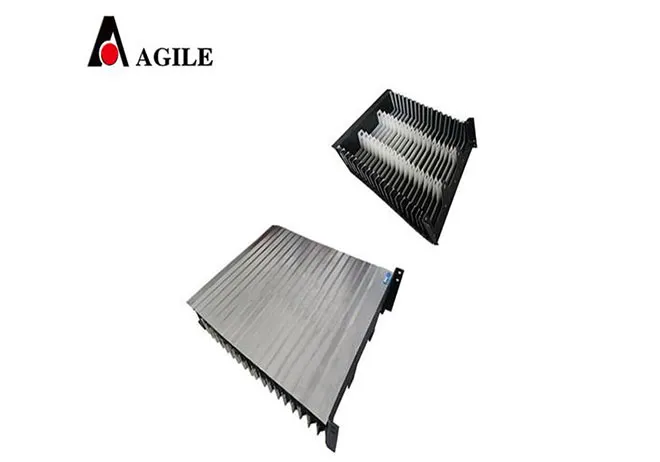

cnc machine used metal swarf chip conveyor

Metal chip conveyors are indispensable in the domain of industrial manufacturing, offering an effective solution for the transportation and management of metal waste materials generated during machining processes. These specialized conveyors are crafted to handle large volumes of sharp, often hazardous metal chips, providing a safe and efficient method for waste disposal and recycling.

The advancements in metal chip conveyor technology also highlight the importance of eco-friendly practices within industrial settings. These conveyors often support recycling efforts by efficiently sorting and transporting metal waste to be reclaimed and repurposed. This not only contributes to sustainability efforts but can also result in significant cost savings for manufacturing companies by minimizing waste. In essence, the role of metal chip conveyors extends beyond simple waste transportation; they are integral to the efficient functioning of manufacturing operations. Their ability to enhance workplace safety, maintain productivity, and support environmental responsibility underscores their value across industries such as automotive, aerospace, and machining. Companies investing in advanced metal chip conveyor systems often find a substantial return on investment. The reduction in machine downtime, enhanced safety measures, and improved waste management processes substantially offset initial acquisition costs. This is why it is vital for facilities to partner with reputable suppliers who can provide sophisticated, reliable solutions tailored to their specific manufacturing needs. As the manufacturing world continues to evolve, embracing these technological innovations becomes paramount. Metal chip conveyors represent a leap forward in managing industrial by-products, ensuring that production environments are both efficient and environmentally conscious. This transformation underscores the significance of selecting the right conveyor system—one that aligns with the operational goals and sustainability commitments of modern industrial enterprises.

The advancements in metal chip conveyor technology also highlight the importance of eco-friendly practices within industrial settings. These conveyors often support recycling efforts by efficiently sorting and transporting metal waste to be reclaimed and repurposed. This not only contributes to sustainability efforts but can also result in significant cost savings for manufacturing companies by minimizing waste. In essence, the role of metal chip conveyors extends beyond simple waste transportation; they are integral to the efficient functioning of manufacturing operations. Their ability to enhance workplace safety, maintain productivity, and support environmental responsibility underscores their value across industries such as automotive, aerospace, and machining. Companies investing in advanced metal chip conveyor systems often find a substantial return on investment. The reduction in machine downtime, enhanced safety measures, and improved waste management processes substantially offset initial acquisition costs. This is why it is vital for facilities to partner with reputable suppliers who can provide sophisticated, reliable solutions tailored to their specific manufacturing needs. As the manufacturing world continues to evolve, embracing these technological innovations becomes paramount. Metal chip conveyors represent a leap forward in managing industrial by-products, ensuring that production environments are both efficient and environmentally conscious. This transformation underscores the significance of selecting the right conveyor system—one that aligns with the operational goals and sustainability commitments of modern industrial enterprises.