Exploring the Uses and Benefits of Loom Tubing Split Techniques and Methods

Understanding Loom Tubing Split A Comprehensive Guide

Loom tubing split is a term often found in the fields of manufacturing, textiles, and industrial engineering. It refers to the splitting of loom tubing, which is a critical component that facilitates the weaving process in textile production. Understanding loom tubing and its splitting process is essential for anyone involved in textile manufacturing or engineering. This article will delve into the importance of loom tubing, the process of splitting, and the implications of this procedure on production quality and efficiency.

What is Loom Tubing?

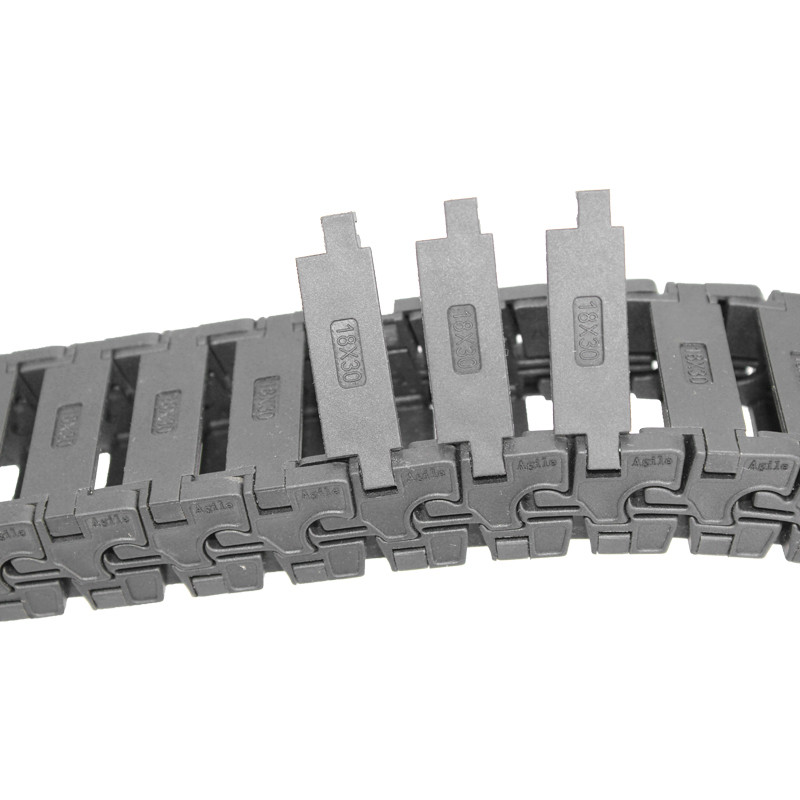

Loom tubing is a protective and supportive material used in weaving machines, commonly referred to as looms. It serves multiple purposes, including protecting the warp yarns, guiding the movement of threads, and ensuring the smooth operation of weaving machines. Loom tubing can be made from various materials, including plastic, rubber, and fabric, each selected based on the specific requirements of the weaving process.

In essence, loom tubing acts as a conduit through which threads are manipulated and interlaced into fabric. The quality of loom tubing directly impacts the efficiency of the weaving process, the quality of the finished product, and the overall productivity of the textile manufacturing unit.

The Process of Loom Tubing Split

The term loom tubing split refers to the process by which loom tubing is divided or cut into specified sections. This process can occur for a variety of reasons, including maintenance, customization, or design adjustments. Splitting loom tubing can be done in several ways, depending on the material and the requirements of the weaving project.

1. Preparation Before splitting loom tubing, it is crucial to prepare the workspace and gather the necessary tools. Proper safety measures should be taken to prevent accidents during the splitting process.

2. Measuring Accurate measurements are vital to ensure that the split pieces will fit correctly into the weaving machine. This step helps avoid material wastage and ensures that the final product meets production specifications.

loom tubing split

3. Cutting The actual splitting can be done using a variety of tools, ranging from specialized cutting devices to standard industrial cutters. The chosen method will depend on the type of loom tubing being used. For instance, rigid plastic tubing may require a saw, while softer rubber tubing can be cut with scissors.

4. Finishing After the tubing has been split, the edges must be finished to prevent fraying or damage during use. This may involve sealing the edges, rounding the corners, or applying a protective coating.

Implications of Loom Tubing Split

Understanding the implications of loom tubing split is essential for ensuring the overall quality and efficiency of the weaving process. Here are some key considerations

- Quality Control Proper splitting of loom tubing is crucial for maintaining quality control in textile production. Poorly split tubing can lead to inconsistencies in thread tension, resulting in defects in the woven fabric.

- Production Efficiency Efficient splitting processes can enhance overall production efficiency. By ensuring that loom tubing is cut accurately and processed quickly, manufacturers can reduce downtime and improve output rates.

- Cost-Effectiveness Effective loom tubing split can also contribute to cost savings. By minimizing waste and reducing the need for excess materials, manufacturers can optimize their resources and increase profit margins.

Conclusion

In summary, understanding loom tubing split is essential for professionals in the textile manufacturing industry. Knowing how to properly split loom tubing can lead to better quality fabrics, improved production efficiency, and cost savings. As the textile industry continues to evolve with advancements in technology and manufacturing processes, staying informed about the best practices regarding loom tubing and its splitting will be critical for success in this dynamic field. As such, manufacturers must prioritize training and efficiency in their operations to remain competitive in the market.