Understanding the Functionality and Benefits of Energy Chain Cables in Modern Applications

Understanding Energy Chain Cables An Essential Component for Modern Machinery

In the realm of modern automation and machinery, the term energy chain cables refers to a specific type of cable management system designed to ensure the reliable transmission of energy and data in dynamic settings. As industries strive for efficiency and reliability, energy chain cables have become indispensable in various applications, ranging from manufacturing to robotics and beyond.

What Are Energy Chain Cables?

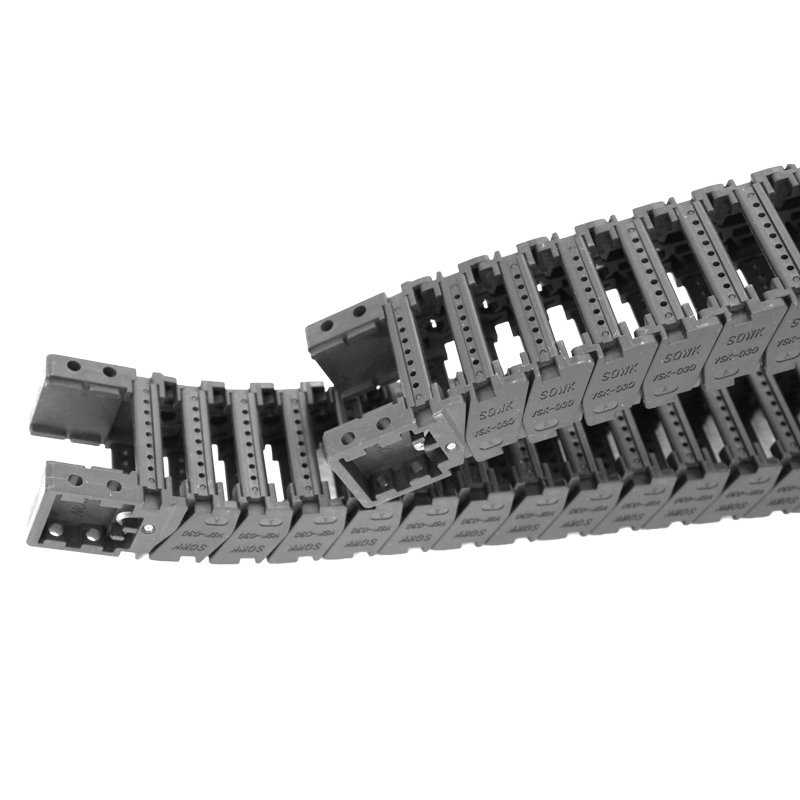

Energy chain cables, also known as energy chains or cable carriers, are specialized systems that protect and guide cables and hoses in moving applications. They are typically made from durable materials such as plastics or metals, designed to withstand wear and tear while ensuring flexibility. Energy chain cables consist of interconnected links thatform a flexible conduit, allowing for the free movement of cables and hoses in machines that involve rotational or linear motion.

Importance in Modern Applications

The significance of energy chain cables cannot be overstated. As machines and equipment become more complex and automated, the need to manage multiple cables efficiently becomes critical. Energy chain cables serve several essential functions

1. Protection These systems guard cables and hoses against mechanical damage from abrasion, pinching, or tangling. By providing a physical barrier, energy chain cables extend the lifespan of these critical components, reducing maintenance costs and downtime.

2. Organization In environments where multiple cables must be routed, energy chain cables help keep them neatly organized. This organization simplifies troubleshooting and repairs while enhancing the accessibility of each cable.

3. Flexibility Energy chain cables are designed to move with the machinery they support. Unlike traditional cable management solutions, they allow for dynamic motion without compromising the integrity of the cables. This flexibility is particularly beneficial in robotic arms, CNC machines, and conveyor systems where repetitive movements are involved.

energy chain cable

4. Efficiency By ensuring that cables and hoses remain our of the way during operation, energy chain cables contribute to the overall efficiency of the machine. This includes minimizing the risk of tangling or snagging, which can lead to operational halts.

Applications Across Various Industries

Energy chain cables are employed across a wide range of industries. In the manufacturing sector, for example, they are utilized in assembly lines where robotic arms require consistent and flexible energy and data supply. In the automotive industry, energy chain cables are critical for conveyor systems that transport vehicles and components through various stages of assembly.

Moreover, in the field of healthcare, state-of-the-art medical devices benefit from energy chain cables to ensure that power and data connections remain secure and unobstructed during operation. Similarly, in the entertainment industry, stage equipment utilizes these systems to manage power cables for lighting and sound systems, enabling seamless performances.

Future Trends

As technology continues to advance, the design and functionality of energy chain cables are also evolving. Innovations such as integrated sensors for monitoring cable wear and advanced materials for improved durability are on the horizon. Furthermore, with the increasing trend towards automation and smart factories, the demand for sophisticated energy chain cable solutions is expected to rise.

Conclusion

Energy chain cables play a vital role in the successful operation of a plethora of modern machines and systems. Their ability to provide protection, organization, flexibility, and efficiency has made them an essential component in various sectors. As industries continue to innovate and embrace new technologies, energy chain cables will undoubtedly advance alongside them, ensuring reliable performance in the dynamic environments of tomorrow. Understanding their importance not only helps in appreciating modern machinery but also highlights the need for effective cable management solutions in our increasingly automated world.