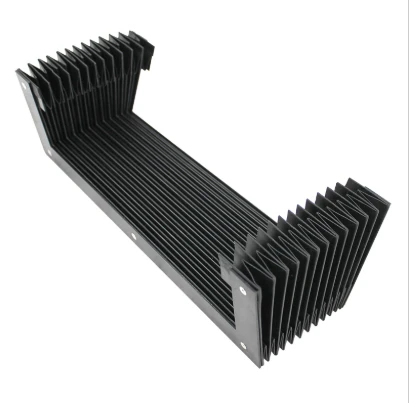

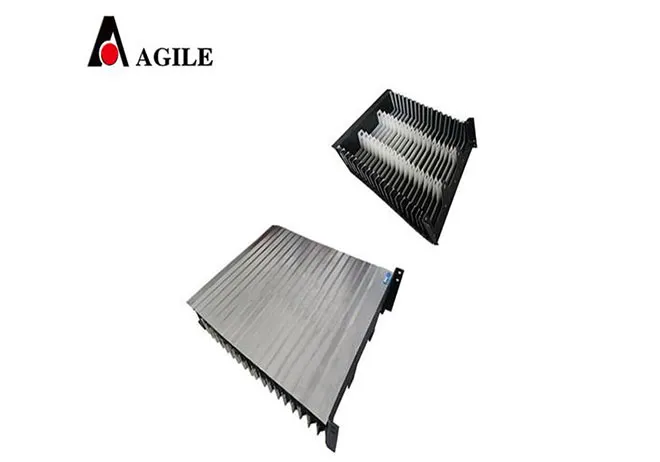

flexible cable carrier

Cable carriers, also referred to as drag chains or energy chains, are integral components in modern machinery and industrial systems. Their design is focused on enhancing the longevity and efficiency of electrical and hydraulic cables, as well as hoses, by protecting them from wear and tear caused by constant movement and environmental factors. Understanding their application, type, and benefits is crucial for any business involved in automation, manufacturing, or heavy machinery operations.

Trustworthiness in cable carrier systems is enhanced through rigorous testing and adherence to international standards. Reputed manufacturers conduct exhaustive testing to ensure their products meet or exceed performance expectations under various stress conditions. Additionally, they maintain certifications from established industry bodies, guaranteeing that the cable carriers not only comply with safety and quality standards but also deliver reliable performance over their operational lifespan. The implementation of cable carriers can dramatically improve the maintenance cycles and safety standards of industrial operations. With proper installation and regular inspections, they minimize the risk of cable damage, which is crucial for continuous and efficient machinery function. By facilitating smooth cable guidance and reducing cable stress points, cable carriers enable smoother operational flows and prevent disruptions that can lead to significant production losses. In conclusion, cable carriers are a vital element in safeguarding complex cable and hose systems in industrial settings. Their careful selection and regular maintenance play a pivotal role in ensuring operational continuity and efficiency. Partnering with seasoned suppliers and leveraging the latest advancements in cable carrier technology ensures that businesses can mitigate potential risks while optimizing the performance of their equipment. This strategic approach not only enhances productivity but also fortifies the investment in industrial infrastructure, fostering long-term growth and stability in a competitive marketplace.

Trustworthiness in cable carrier systems is enhanced through rigorous testing and adherence to international standards. Reputed manufacturers conduct exhaustive testing to ensure their products meet or exceed performance expectations under various stress conditions. Additionally, they maintain certifications from established industry bodies, guaranteeing that the cable carriers not only comply with safety and quality standards but also deliver reliable performance over their operational lifespan. The implementation of cable carriers can dramatically improve the maintenance cycles and safety standards of industrial operations. With proper installation and regular inspections, they minimize the risk of cable damage, which is crucial for continuous and efficient machinery function. By facilitating smooth cable guidance and reducing cable stress points, cable carriers enable smoother operational flows and prevent disruptions that can lead to significant production losses. In conclusion, cable carriers are a vital element in safeguarding complex cable and hose systems in industrial settings. Their careful selection and regular maintenance play a pivotal role in ensuring operational continuity and efficiency. Partnering with seasoned suppliers and leveraging the latest advancements in cable carrier technology ensures that businesses can mitigate potential risks while optimizing the performance of their equipment. This strategic approach not only enhances productivity but also fortifies the investment in industrial infrastructure, fostering long-term growth and stability in a competitive marketplace.