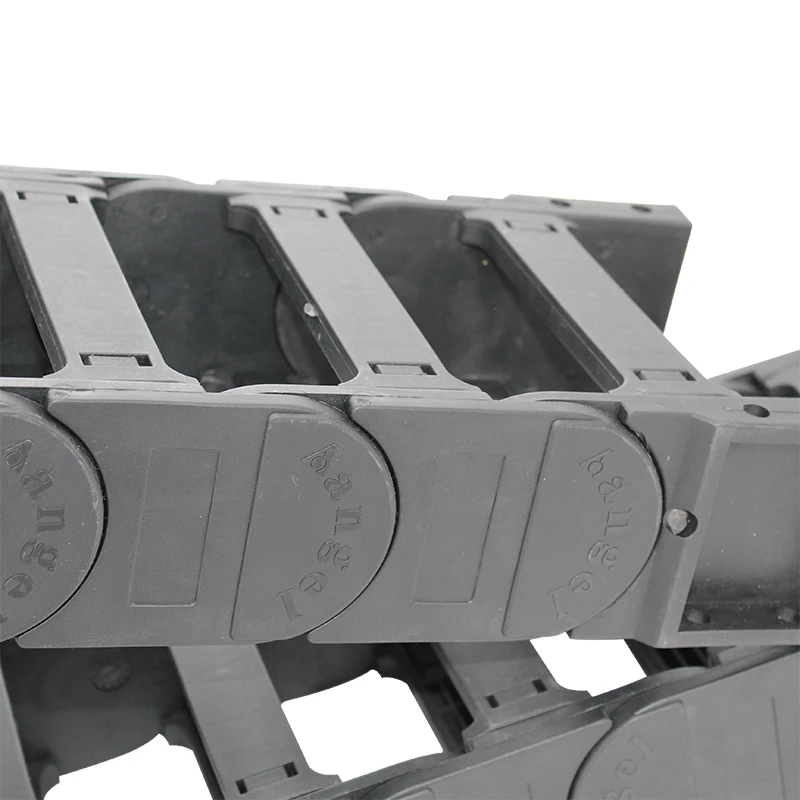

nylon flexible wire loom corrugated bellow conduit hose pipe

Navigating the vast world of conduits, the 10mm corrugated conduit stands out as a versatile and essential component, particularly prized for its utility in wiring and cable management across numerous applications. When dealing with the installation and protection of electrical cables, selecting the right conduit is crucial to ensure not only safety but also the longevity and efficiency of the systems deployed.

Expertise in conduit systems further confirms that proper installation is key to performance and safety. The corrugated design, while inherently flexible, requires careful handling to maximize its protective capabilities and avoid any deformation that could compromise cable protection. In practice, installers are advised to adhere strictly to manufacturer guidelines, employing the necessary cutting tools and securing measures such as clips or ties to prevent movement or vibration that may occur in environments like automotive engine bays. Authoritatively speaking, companies integrating 10mm corrugated conduits into their systems often report significant reductions in maintenance costs and downtime. The conduit’s protective nature against physical impacts and environmental factors lowers the need for frequent inspections and cable replacements, a critical benefit in industries where ease of access may be limited post-installation. A testament to its engineering efficiency, the conduit supports not just straight runs but can be adapted to varying circuitous paths without sacrificing its protective role. Trustworthiness, an invaluable trait in the electrical components industry, is bolstered by the 10mm corrugated conduit’s compliance with industry standards and certifications. Safety certifications from reputable bodies ensure that the conduit lives up to performance claims, providing both operators and end-users with peace of mind. Furthermore, being a staple choice in many safety-critical applications underscores its reliability and effectiveness. The significance of the 10mm corrugated conduit in such applications cannot be overstated. Known for its balance of rigidity and flexibility, it safeguards against the elements, mechanical stresses, and unforeseen challenges intrinsic to the environments they are used in. By understanding the specifics of this conduit’s application needs, one can leverage its myriad benefits, crafting installations that are both high-functioning and enduring. Embracing the knowledge and expertise surrounding this component can lead to decisions that significantly enhance both operational effectiveness and economic efficiency in a variety of settings.

Expertise in conduit systems further confirms that proper installation is key to performance and safety. The corrugated design, while inherently flexible, requires careful handling to maximize its protective capabilities and avoid any deformation that could compromise cable protection. In practice, installers are advised to adhere strictly to manufacturer guidelines, employing the necessary cutting tools and securing measures such as clips or ties to prevent movement or vibration that may occur in environments like automotive engine bays. Authoritatively speaking, companies integrating 10mm corrugated conduits into their systems often report significant reductions in maintenance costs and downtime. The conduit’s protective nature against physical impacts and environmental factors lowers the need for frequent inspections and cable replacements, a critical benefit in industries where ease of access may be limited post-installation. A testament to its engineering efficiency, the conduit supports not just straight runs but can be adapted to varying circuitous paths without sacrificing its protective role. Trustworthiness, an invaluable trait in the electrical components industry, is bolstered by the 10mm corrugated conduit’s compliance with industry standards and certifications. Safety certifications from reputable bodies ensure that the conduit lives up to performance claims, providing both operators and end-users with peace of mind. Furthermore, being a staple choice in many safety-critical applications underscores its reliability and effectiveness. The significance of the 10mm corrugated conduit in such applications cannot be overstated. Known for its balance of rigidity and flexibility, it safeguards against the elements, mechanical stresses, and unforeseen challenges intrinsic to the environments they are used in. By understanding the specifics of this conduit’s application needs, one can leverage its myriad benefits, crafting installations that are both high-functioning and enduring. Embracing the knowledge and expertise surrounding this component can lead to decisions that significantly enhance both operational effectiveness and economic efficiency in a variety of settings.