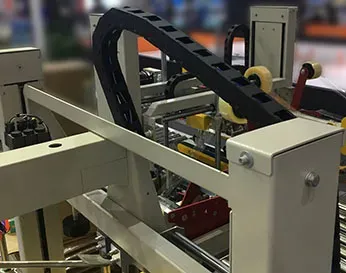

cps drag chain

Understanding CPS Drag Chains A Comprehensive Guide

In the world of mechanical engineering and industrial applications, the term CPS drag chain often appears, particularly in the context of cable management and motion systems. A CPS (Cable Protection System) drag chain is a vital component designed to protect and manage the movement of cables and hoses in various machinery and equipment. The drag chain is especially prevalent in settings where mobility, flexibility, and safety are paramount, such as in CNC machines, robotics, and automated production lines.

What is a CPS Drag Chain?

A CPS drag chain, also referred to as an energy chain, is typically a series of interconnected links that create a flexible channel for cables, hoses, or wires. This system allows for the safe movement of these components while reducing wear and tear caused by frequent motion. The primary purpose of a drag chain is to prevent tangling, abrasion, and damage to the cables, thus enhancing the longevity and reliability of the equipment.

Key Features and Benefits

1. Protection One of the most significant advantages of using a CPS drag chain is its ability to protect sensitive cables and hoses from external damage. In environments where equipment is frequently in motion, cables can easily become damaged, leading to costly downtime and repairs. The drag chain minimizes this risk by encasing the cables securely.

2. Organization Drag chains help to organize wires and hoses, keeping them neatly arranged and preventing clutter in workspaces. This organization is not only aesthetically pleasing but also enhances the efficiency of maintenance and troubleshooting.

3. Flexibility and Movement CPS drag chains are designed to accommodate various types of movements, including linear, angular, and circular motions. Their flexible design allows them to bend and twist while maintaining a tight grip on the cables.

cps drag chain

4. Customization Many manufacturers offer customizable drag chains, allowing businesses to select the size, material, and design that best suits their specific needs. This adaptability is crucial in industries where equipment designs are continually evolving.

5. Ease of Installation CPS drag chains are relatively easy to install and can be integrated into existing systems with minimal disruption. This feature is particularly advantageous for businesses looking to upgrade their machinery without extensive downtime.

Applications of CPS Drag Chains

CPS drag chains are used across a wide range of industries, including

- Manufacturing In automated assembly lines, drag chains ensure that cables remain organized and protected, even as machinery moves and operates continuously. - Robotics Robots often require complex cable management systems due to their intricate movements. CPS drag chains provide the necessary support, allowing robots to function efficiently without cable interference. - CNC Machining CNC machines involve precise movements, and the associated wiring needs protection from potential wear and tear. Drag chains help maintain order and safety. - Printing and Packaging In these industries, equipment often operates under high speeds and loads. Utilizing drag chains helps in ensuring that cables are secure and functional.

Conclusion

In summary, a CPS drag chain is an indispensable component for ensuring the safe and efficient operation of machinery in various industries. By providing protection, organization, flexibility, and ease of installation, these systems play a critical role in enhancing operational efficiency and reducing maintenance costs. As technology continues to evolve, the designs and applications of CPS drag chains are likely to advance, making them even more integral to the landscape of modern engineering and automation. Implementing a drag chain system can significantly contribute to a company’s reliability and productivity, making it an investment worth considering.