1 4 inch split loom

Understanding 1 4 Inch Split Loom A Comprehensive Guide

When it comes to efficient organization and protection of wires, cables, and hoses, the use of split loom tubing has gained significant popularity across various industries. One specific type that has garnered attention is the 1 4 inch split loom. This guide delves into what split loom is, its advantages, and its applications, with a special focus on the 1 4 inch variant.

What is Split Loom?

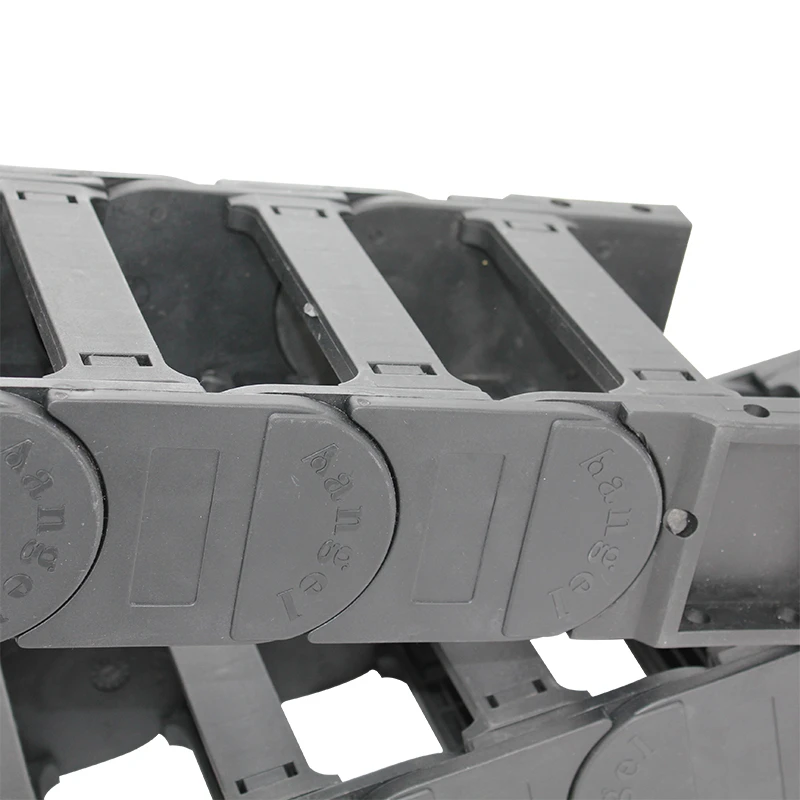

Split loom tubing is a type of protective conduit made from flexible plastic, predominantly polyethylene or polypropylene. It features a split along the length, which allows for the easy insertion of cables and wires. The open design enables quick access for repairs or modifications while offering a level of protection against abrasion, heat, and chemical exposure. The term “split loom” derives from its ability to wrap around wires like a loom wraps thread, providing structure and support.

1 4 Inch Size Specification

The designation 1 4 inch refers to the diameter of the split loom tubing, which typically equates to 1.25 inches when interpreted correctly. This size is versatile, making it suitable for a variety of applications ranging from automotive wiring to electrical installations in commercial buildings. The expanded inner diameter accommodates multiple cables, allowing for easy management without excessive bundling.

Advantages of Using Split Loom Tubing

1. Protection One of the primary benefits of split loom is the protection it provides for wires against abrasion and external elements. This is particularly valuable in environments where cables may be subject to wear and tear or exposure to chemicals.

1 4 inch split loom

2. Organizational Efficiency The split design allows for organized bundling of multiple wires without the need for heat-shrink tubing or other bundling methods. This reduces clutter, making it easier to trace wires during maintenance or troubleshooting.

3. Flexibility and Ease of Use The flexible nature of split loom tubing allows it to bend and adapt easily to tight spaces and corners, facilitating installation in complicated layouts. Moreover, its lightweight composition prevents unnecessary strain on cables.

4. Temperature and Chemical Resistance Split loom made from high-quality materials can endure varying temperatures and resist chemicals, making it suitable for diverse operating conditions, including automotive and industrial applications.

Applications of 1 4 Inch Split Loom

The 1 4 inch split loom is widely used in various sectors

- Automotive It protects wiring harnesses from heat and mechanical damage, ensuring that vehicles function smoothly. - Electronics In electronic assemblies, it organizes internal wiring for cleaner designs and easier repairs. - Construction In new builds, it safeguards electrical wiring and HVAC systems against damage during the construction process.

Conclusion

In summary, the 1 4 inch split loom tubing offers an effective solution for protecting and organizing wires and cables across numerous applications. Its combination of flexibility, durability, and protective qualities makes it an ideal choice for industries that require reliable wire management solutions. By incorporating split loom tubing into your wiring systems, you can enhance longevity, safety, and efficiency in your projects. Whether you're in automotive, electronics, or construction, split loom should be a key component of your wiring strategy.