cable chain cnc

Understanding Cable Chains in CNC Machines

In the realm of CNC (Computer Numerical Control) machining, efficiency and precision are paramount. Various components contribute to these attributes, but one that often goes overlooked is the cable chain. Cable chains, also known as energy chains, play a critical role in maintaining the functionality and efficiency of CNC machines. This article explores the importance of cable chains, their design, benefits, and applications within the CNC industry.

What Are Cable Chains?

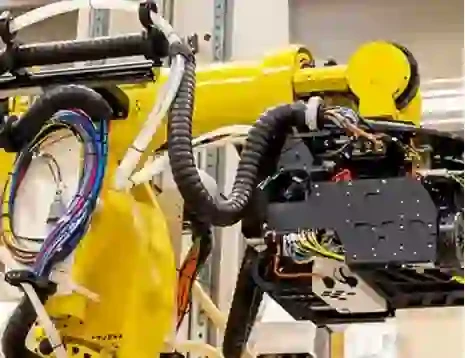

Cable chains are protective conduits that carry and manage the various cables and hoses used in CNC machines. They are designed to guide these cables along a predefined path, protecting them from wear and tear due to movement. The chains are made from durable materials, such as plastics or metals, that can withstand the challenging conditions often present in machining environments.

Design and Functionality

The primary purpose of a cable chain is to ensure that cables and hoses do not become entangled or damaged during machine operation. A typical cable chain features multiple links connected together in a flexible yet robust configuration. This design allows the chain to flex and move as the CNC machine operates, accommodating the dynamic movements of the machine's components.

One of the key design considerations for cable chains is the selection of the right size. The chain must be large enough to accommodate the bundled cables while ensuring sufficient space for movement without excessive slack. Furthermore, cable chains come in various shapes, including open or closed profiles, depending on the specific application requirements.

Benefits of Using Cable Chains in CNC Machines

1. Protection from Damage The primary function of cable chains is to safeguard cables and hoses from abrasion, cutting, and environmental hazards. This protection helps extend the life of the components and reduces the likelihood of machine downtime due to cable failure.

2. Improved Organization Cable chains help keep cables neatly organized, which minimizes clutter in the machine workspace. This organization not only enhances visual clarity but also simplifies maintenance and replacement processes.

3. Increased Flexibility Because cable chains can accommodate various bending angles and motions, they provide the flexibility needed for complex CNC operations. This adaptability enables more efficient machining processes and enhances the machine's overall performance.

cable chain cnc

4. Efficiency in Operation With the cables properly managed and protected, CNC machines can operate more efficiently. Reduced wear on cables leads to fewer repairs and longer service intervals, contributing to a lower overall cost of ownership.

5. Enhanced Safety By neatly routing cables and hoses, cable chains reduce the risk of tripping hazards in the workspace. This increased safety can lead to fewer workplace accidents and a more conducive working environment.

Applications in CNC

Cable chains are widely used across various CNC applications, from milling and drilling to laser cutting and 3D printing. In each of these processes, the movement of the machine’s components may require extensive routing of electrical cables and pneumatic hoses.

1. Milling Machines In milling applications, cable chains help manage the complex interplay of power, control, and feedback systems essential for precision cutting.

2. Laser Cutting Machines The dynamic motion of laser cutting heads necessitates proper cable management to ensure uninterrupted performance and maintain cutting quality.

3. 3D Printers As 3D printing technology evolves, the need for efficient cable management systems becomes increasingly important. Cable chains help navigate the rapid movements often seen in high-speed 3D printers.

4. Robotic Arms Robotic CNC systems benefit greatly from cable chains, as they must handle a large number of cables and hoses while allowing for full-range motion.

Conclusion

In summary, cable chains are an indispensable component of modern CNC machinery. By providing protection, organization, and flexibility, they enhance the efficiency and safety of CNC operations. As technology continues to advance, the role of cable chains is likely to become even more significant, ensuring that CNC machines can meet the demanding needs of various industries. Understanding their significance can help manufacturers optimize their CNC operations and extend the longevity of their machines.